The modern consumer is known for suchproducts like EZ-200. Fiberglass of this brand belongs to the group of heat-insulating materials, which consist of twisted glass strands of aluminosilicate glass, whose diameter can vary from 0.1 to 20 microns. In the manufacturing process, paraffin emulsion is added to these threads, which acts as a lubricant. On weaving looms weave threads, as a result of which it is possible to obtain a canvas that is chemically resistant and does not burn. It does not wear or decompose.

Specifications

EZ-200 - fiberglass, which has a highstrength, it is able to maintain dimensions during processing and operation, the material resists pushing well. It is non-toxic, non-explosive, capable of undergoing exposure to high temperatures and does not ignite. Fiberglass is perfectly environmentally safe, and among its main characteristics can be distinguished thickness, surface density, as well as breaking load.

The first parameter is equal to the limit of 0.190 mmmay vary in both directions by 0.01 mm. Surface density is measured in g / m² and is equal to 200 for this type of fiberglass. Upwardly, the parameter can vary within 16, while downwards it can be within 10. Builders are often interested in breaking load. According to the basis and duck, this parameter can be equal to 1127 and 1078 N (kgf), respectively. You may also be interested in the density of the fabric on the basis and on the duck, in this case the parameters are 10 and 9 threads per centimeter.

ЭЗ-200 – стеклоткань, которая имеет ширину в within 95 cm, while the roll length is 150 m. The weave is plain, the type of sizing is paraffin emulsion. The warranty period for the storage of this material from the date of manufacture is 2 years. Mass fraction of not less than 1% during calcination.

Scope of use

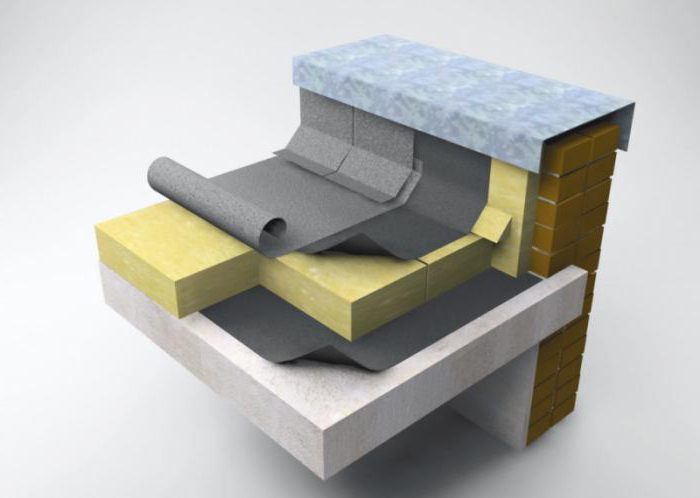

Thermal insulation fiberglass is used inas an independent material. It mainly serves as thermal insulation for boilers, pipes, and gas turbines. It can also be used as thermal insulation, in the form of a coating layer.

Названная ткань применяется для изготовления clothes for metallurgists, electric welders and firefighters, and in the chemical industry filters for toxic gases, acids and alkalis are made of material. Fiberglass is used as the basis for the manufacture of fiberglass for various purposes and types, and the material is impregnated with different resins.

More on the application

EZ-200 - fiberglass, which forms the basisbody parts, namely cars, boats and boat elements. It also serves as an integral part, where chemical resistance of materials is important. These include the manufacture of tanks, tanks and pipes that are used in the chemical industry. It is used for electrical insulation materials of printed circuit boards, in addition, it serves as the basis for the circuits of radio receivers, instruments and computers.

On the fiberglass mica is stuck onsilicone varnish, in the next stage, the material undergoes pressure, as a result of which it is possible to obtain electrical insulating structural material, which is widely used in all areas of the energy industry. EZ-200 fiberglass fabric, the characteristics of which are presented in the article, is used to make items at home, used to repair damaged body parts and machine bumpers. If you have in stock fiberglass of this brand and epoxy resin, you can repair parts of any shape.

Use in construction

EZ-200 fiberglass fabric, technical characteristicswhich were presented above, is used in construction. One of the products that is made of fiberglass is fiberglass reinforcement. It was developed as a replacement for steel reinforcement.

For a long time steel protruded inas the only material that has the necessary properties for this, namely durability and strength. Since there was no alternative, we had to put up with the shortcomings of steel. However, the development of technology has made it possible to manufacture materials with inaccessible properties. That, in turn, allowed to change the standards for the production of building materials.

Replaced steel fiberglasscomposite reinforcement. It has high reliability and durability, low weight and does not corrode. In addition, it is resistant to the adverse effects of moisture, has a low thermal conductivity and does not conduct electricity. Additional qualities include chemical inertness.

Fiberglass as an additive

EZ-200 fiberglass fabric, the certificate of which you can find in the article, forms the basis of glass fiber, it is added to concrete mixes, and it performs the role of a binding element.

Normal concrete mix when curingshrinks and microcracks appear as a result. This can adversely affect the quality of structures and their durability. If fiber is added to the solution, then fresh concrete will not be covered with cracks when it hardens, since fiberglass fibers will stop the germination of defects in the early stages.

Manufacturers and state standards

Fiberglass EZ-200, GOST which looksas follows: 19907-83, manufactured today by many companies. Among others we can distinguish "Polotsk fiberglass." This manufacturer is today one of the leading manufacturers of fiberglass and products based on it in the world.

The plant was founded in 1957, and in JanuaryIn 1965, its second stage was launched, which had a full production cycle from production to processing into fiberglass cloth. This industrial complex has an area of 1 million square meters, it has equipment, which has more than 1000 units.

Если вам нужна стеклоткань ЭЗ-200, Ярославль тоже can offer your goods. In this city there are many companies that offer products for sale. For example, the plant "Range" manufactures fiberglass sputnik in the range. Whereas, KSM offers fiberglass of standard width to the attention of consumers. It should be noted also “TK Energokomplekt”, which produces insulating, roofing and other building materials.

Alternative ways to use fiberglass

Стеклоткань ЭЗ 2 200, технические характеристики which you will need if you plan to purchase this material, is used today in other areas. Depending on the thickness of the material, consumer goods are made of it. These include:

- sanitary parts;

- leisure and sports goods;

- boxes and containers;

- medical products;

- various types of household pipes;

- electrical products.

As for plumbing parts, here you caninclude septic tanks, swimming pools, toilets and showers. If you are interested in products for recreation and sports, then among them you can select paddles for rowing, fishing rods, as well as ski poles. Containers have found their use as containers for solid waste. In dentistry, fiberglass is used as fillings, as well as fixed prostheses and tapes for splinting teeth.

Fiberglass E3-200 is actively used inorthopedics - canes, prostheses and crutches are made from the named material. But in everyday life fiberglass is used for the manufacture of antennas, flagpoles and holders. But this list cannot be called complete, every day the areas of use of fiberglass are expanding, the material covers new areas of activity.

Production features

Fiberglass continuous fiber moldby pulling the molten strands from the glass melt. At the same time, dies are used, and the number of holes can vary from 200 to 4000. At the same time, mechanical devices are used, the fiber is wound on a bobbin. The diameter of the fiber will depend on the diameter of the die and the speed of extrusion.

The process can be carried out in one or two stages.In the first case, the fiber is drawn out of glass melt and comes from glass melting furnaces. In the second, previously obtained balls of glass, glass or air-glass are used. The latter are pieces of fused glass, which are produced in furnaces or glass melting machines, called vessels.

If we are talking about staple glass fiber, then it is formed by the method of blowing a jet of glass, which is affected by steam. Hot gas or air can be used.

For reference

Fiberglass EZ-200, the manufacturer of which canto be selected independently, has a certain tensile strength, microscopic scratches and defects on the surface affect this parameter. For constructive purposes, as a rule, glass is used, the tensile strength of which is 50 MPa. Glasses have a Young's modulus within 70 GPa.

Fiberglass cost

Fiberglass brand E3-200 is sold at a price of 30rub. per square meter. It is a white fabric, which consists of the smallest glass yarns. The material is wound on a paper-bakelite sleeve or wooden roller. Foam rubber is packaged in plastic wrap that facilitates transportation.

Возможно изготовление стеклоткани с окрашиванием in different colors. It can be used as a coating material in its raw or impregnated form. You can use them for thermal insulation of pipelines, boiler plants and gas turbines, as well as a shell in the manufacture of basalt-based insulation mats. Fiberglass is used indoors and outdoors, as well as underground.

Conclusion

Стеклоткань сегодня используется повсеместно, что due to its unique characteristics, among them it is necessary to highlight the high strength, fire safety, dimensional stability, as well as significant elongation at break. The structure is filled, the material is moisture resistant and high rigidity. You can count on thermal and chemical resistance.