Isoplast is currently known andpopular roofing material. It is more expensive than roofing felt, but it has a much better performance characteristics. There are several types of this coating, which differ mainly in purpose. Isoplast different companies produce.

What is the material

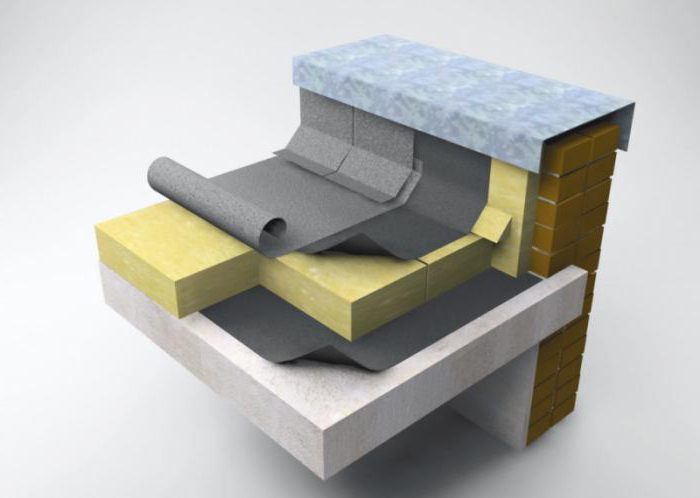

Isoplast for sale, specificationswhich are listed below in rolls one meter wide. The length of the strip at the same time is 10 m. Externally, this material resembles the usual roofing felt. However, the basis for it is not cardboard, but fiberglass or polyester. Hence its increased tensile strength. On both sides, the base is coated with bitumen with polymer APP, IPP, or similar polyols. From below (and sometimes from above) the strip is glued with a protective film. When installing it just removed. On some varieties, scaly, coarse or fine-grained dressings are applied on top.

Material advantages

The advantages of this type of roofing include the following:

- Easy installation. Laying can produce two people.

- Tensile strength and cracking. When laying do not need to be especially careful. Isoplast is rather difficult to tear (unlike, for example, from roofing felt).

- Resistance to temperature changes. You can work with this material even in very cold weather.

- Durability. Isoplast can last more than twenty years.

- Resistance to damage by bacteria.

- Environmental Safety.

- Full waterproof.

- Low weight. Raising the rolls to the roof, as well as transporting them is very easy.

Disadvantages of the material

К минусам этой разновидности кровельной защиты can only be attributed to a fairly high cost. However, given the fact that isoplast serves for a very long time, this drawback is not very significant. Also a minus of this material is its vulnerability to sharp and cutting objects. Therefore, some caution during its installation and operation must still be observed.

Isoplast: technical specifications

Of course, before you acquire the material, you should find out exactly what properties it has. The table below presents its main technical characteristics.

Parameter | "P" | "TO" |

Weight (kg) | 3.0-5.5 | 4.0-5.0 |

Water absorption (% by weight during the day) | 1 | 1 |

Water resistant | Absolute | Absolute |

The basis | Fiberglass or polyester | Fiberglass or Polyester |

Breaking strength (N / 50 mm) | 360 and higher | 600 - polyester, 800 - fiberglass |

Flexibility on R10 | Without kinks at a temperature of at least -15 degrees | Not less than -15 degrees |

Heat resistance | Maximum 120 degrees | 120 degrees |

Varieties of material

When pasting the roof with any kind of rollCoatings are usually arranged for reliability in several layers. Isoplast in this respect is no exception. Most often 2-3 layers of it are put on the roof of a house. At the same time, the lower ones, unlike the upper ones, are not. Depending on the purpose of the material, thus, is divided into labeled "P" (lining) and "K" (roofing). The first is used in the lower layers. For the top of the device should be used roofing isoplast. Technical characteristics of both varieties are given in the table above. They are valid for all modifications of the material. As you can see, the reliability of this roofing is very good.

Isoplast EPP: technical characteristics

As can be judged by the labeling, this materialused in the lower layers of the coating. Its base is polyester. Two letters "p" are used in the labeling because both the bottom and the top of this type of isoplast strip are covered with plastic wrap. The most common type of EPP is used to repair the roof, as well as to cover horizontal roofs. After the letters in the marking of isoplast usually numbers appear (for example, 4.0). They denote the weight of a square meter strip. That is, the greater the number, the thicker the hydro insulator. Thus, isoplast EPP 4, the technical characteristics of which correspond to the properties of the “P” group presented in the table, has a smaller thickness than the material labeled 5.

Isoplast HPP

The scope of this variety is the samelike the EPP. Their differences are only in that CPP is made on the basis of fiberglass, not polyester. The polyethylene film, with which the strips are covered on both sides, prevents the rolls from sticking together during storage and transportation even in hot weather. Having bought the material, you will not be disappointed as it sometimes happens when you purchase roofing felt.

Isoplast EMI

This modification of the material isoplast "P"(technical specifications are the same as for all lining variants) also used in the lower layers of the carpet. But in this case, the front side of the strips is not covered with plastic wrap, but sprinkled with fine quartz sand. The use of such material increases the reliability of the entire coating as a whole.

Isoplast ECP

The material of this variety is applied inas a finishing layer in the roofing carpet. For the lower layers it can not be used. From above isoplast ECP, the technical characteristics of which allow it to be used for any kinds of roofs, can be processed with scaly (vermiculite) or coarse slate dressing. This significantly increases the resistance of the surface to adverse natural factors, as well as extends the service life of the roofing carpet. Bottom strips are covered with a protective film. Sometimes fine sand is also used instead.

Isoplast DP

This kind of material is used for leveling steam. It is made on the basis of fiberglass. There are several modifications: DHP-1.5 ... DHP-2.5.

Use of isoplast to protect roofs

Стелить рассматриваемый материал допускается на absolutely any basis. It can be either concrete (high-rise buildings) or crate made of wood or plywood. In the first case, the surface is pre-primed. It is possible to use this roofing material in any climatic regions of Russia.

В том случае, если кровля покрывается впервые, At least two layers of material should be laid. At the same time, as has been said before, isoplast “P” is laid down below, “K” above. If the roof has already been covered with some roll material, it is allowed to use only one layer - “K”. The joints (chimneys, skylights) and joints (valleys) should be laid in several layers. In this case, it is possible to use both isoplast EPP 4, whose technical characteristics make it just an ideal option for this purpose, and EPP 5 or modifications of the HPP.

Stripes are stacked with overlap as inhorizontal and vertical. On pitched roof material is fused from top to bottom. At installation use a special skating rink for rolling strips. For the top layer, use isoplast ECP 4-5, the technical characteristics of which make it possible to build a very durable, absolutely waterproof and maintainable roof.

Correction of damaged coatings is performed as follows:

- At the site of bloating, the material is cut crosswise.

- The corners are unbent and heated from below by a gas torch.

- Then they are put in place and tightly pressed.

- A patch is placed on top of the damaged area.

The rules for installation of isoplast in the case of its use as a waterproofing material are the same. Before sticking, the surface should be carefully prepared, cleared of dirt and leveled.

As you can see, isoplast, technical characteristicswhich are presented above - the material is very high quality, reliable and durable. Even despite the rather high price, it certainly is worth using it to cover roofs. Due to its durability and reliability, it will pay for itself very quickly.