Caliper refers to the class of universalmeasuring instruments of high accuracy. This device is designed to determine the external and internal dimensions of small parts, the depth of the holes and other parameters. Knowing how to measure with a caliper, you can easily set the linear values of any objects, including threaded connections on the hardware.

Features of the use of calipers

Convenience and ease of use of thistools cause its widespread use not only in the manufacturing sector, but also in the home. There are three types of calipers: vernier, dial and digital, differing in their design. The most popular is the first option. Such a tool has a mechanical structure, so there is nothing to break there. With careful handling (it is necessary to protect the device from deformation and rust) its service life is practically unlimited.

Measure with a caliper as a micrometer, i.e.up to tenths of a millimeter, allows the nonius scale. The design of the tool provides for the possibility of fixation of the object being measured both from the outer and from the inner side, due to which the probability of error is reduced to zero.

Structural elements of devices

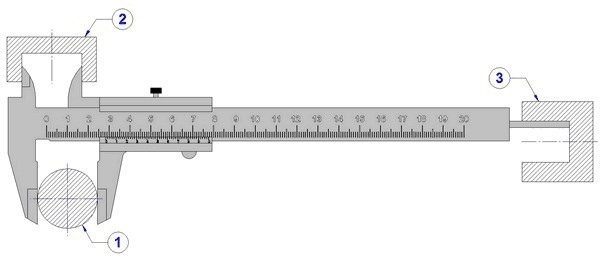

To understand how to measure withcaliper, you need to understand its design. The instrument got its name in honor of the bar, on which the main scale is located. An additional scale is a nonius, designed to determine tenths or hundredths of a millimeter when it is necessary to obtain the most accurate results.

The design of a mechanical vernier caliper consists of:

- bars with the main scale;

- moving frame with Nonius scale;

- sponges for measuring internal surfaces;

- sponges for measuring external surfaces;

- depth gauge ruler;

- screws for fixing the frame.

Some models have a double scale, which allows measuring with a caliper in both millimeters and inches. The remaining structural elements, as a rule, do not have differences.

How to measure external surfaces with a caliper

Для получения точных данных о внешних размерных the parameters of the object, it must be fixed using the lower jaws of the tool. This operation is performed by preliminarily extending the jaws a little more distance than the size of the measured part, and their subsequent shift against the stop into the surface of the product. After the lower caliper jaws are securely fixed on the outer surfaces, the reference point on the moving scale will take a certain position on the main scale and will show the size of the part.

How to measure the internal diameter of a part with a caliper

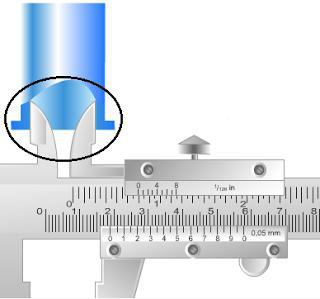

Before performing this operation elementsthe device is shifted to the stop, after which the sponge to determine the distance between the inner surfaces is placed in the hole. Next, they are bred until it stops in the wall and fixed in this position. Knowing how to measure the diameter of a caliper, you can measure the internal planes of any other shape.

Depth determination

This operation is performed usingdepth gauge. The end of the caliper rest in the upper part of the part, and the depth gauge lead into the hole until it stops. The depth of the measured item will be displayed on the main scale.

Measurement of threaded connections

Determining the size of the internal and external surfaces of parts is a simple operation and familiar to many from the school lessons of labor. But not everyone knows how to measure thread with a caliper.

This procedure may be required in differentcases, for example, if the bolt is non-standard or it is necessary to measure the fastener without dismantling the screw connection. Below are examples of how to measure bolts and nuts with a caliper in various situations.

- Determining the length of the bolt screwed into the part.This operation is performed using a depth gauge. Consistently measured are the height of the bolt head, the thickness of the washer (if any), the thickness of the intermediate part and the height of the part of the bolt stem protruding from the back side of the part. The obtained values are summed up, and then determine the size of the fastener using special tables matching the lengths of the bolts and the size of their turnkey heads.

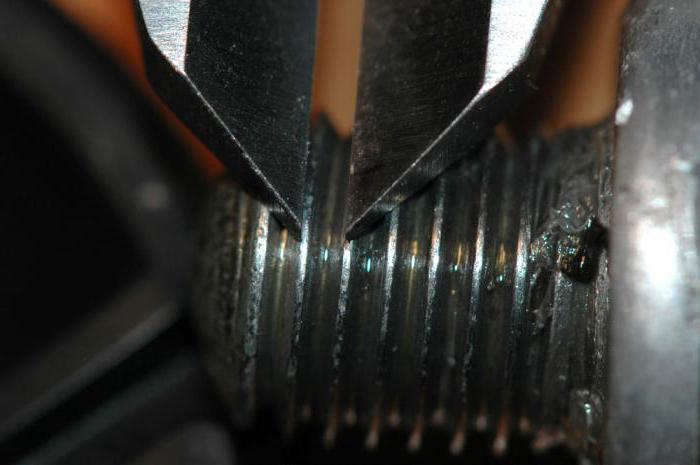

- Определение диаметра резьбы.This parameter is measured by the protrusions, not by the grooves of the thread. Between the caliper jaws, the bolt is placed in a vertical position and measurements are taken. If the obtained indicator does not correspond to the standard dimensions shown in the table, the depth of the thread is measured using a depth gauge. After this, the doubled value of the second is subtracted from the first result and thus it is determined whether part of the thread profile was cut. Damaged hardware must be replaced.

- Bolt thread diameter measurement, fully"Recessed" in the part, without dismantling the connection. For this, an external caliper gauge is used, by means of which the dimensions of the head and the diameter of the projections are established. Further detail is identified using tables.

- Measurement of thread pitch.Using a caliper, determine the height of the bolt rod and its outer diameter, and then count the number of threaded turns on it. The ratio between these indicators will be the tangent of the angle of inclination of the thread.

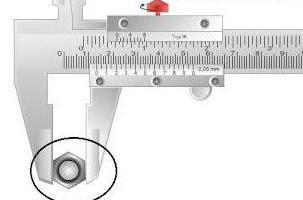

- Measuring the thread diameter of the nuts.This operation is carried out using internal caliper jaws. When using some models of tools, it is necessary to add to the obtained value the thickness of the jaws, which is indicated on the rod.

Taking testimony

First of all, it should be noted that the accuracy of the readings depends on the cleanliness of the surfaces of the part, therefore, before measuring with a caliper, it is necessary to remove dirt and grease from the products.

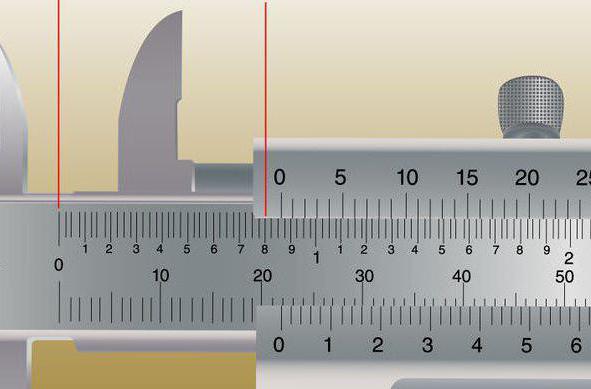

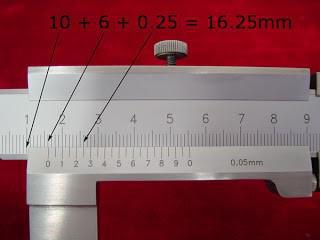

Fixing the tool jaws on the part, onThe main scale is the control stroke, which is located on the left in the immediate vicinity of the zero vernier stroke. This will be the size of the measured surface in millimeters.

Further readings are read in fractions of a millimeter.This operation is performed by finding the division closest to the zero bar and coinciding with the bar on the scale of the bar. As a result of the addition of its serial number and the price of division of the Vernier, the required indicator is calculated. The most popular models of calipers division price is 0.1 mm.

The total value of the instrument is obtained by summing the results in millimeters and in millimeter fractions.

Rules of operation of the caliper

Чтобы измерительный инструмент смог прослужить faithfully for many years, it is necessary to follow simple rules for its operation and storage. First of all, avoid mechanical damage that may occur as a result of a fall or force impact. In addition, in the process of measuring the parts you should not allow the caliper jaws to tilt. To prevent this from happening, they need to be fixed in a certain position on the measured part with the help of a locking screw.

Store the device only in a soft case orhard case. The second option is preferable, as it can provide protection against accidental deformations. The place to store the calipers should be chosen so as to prevent sawdust from various materials, dust, water, chemical mixtures, etc. Plus, the risk of heavy objects falling onto the instrument should be excluded.

After each use of the caliper, it should be thoroughly wiped with a clean, soft cloth.

Naturally, we should not forget about compliancesafety rules for the operation of this device. At first glance, it does not pose any threat to health, but this is not entirely true. The fact is that the ends of the sponges for measuring internal dimensions are quite sharp, so you can easily get hurt about them when carelessly handling them. The rest of the tool is completely safe.