Ventilation systems in most cases havethe design calculated on assignment or forcing of air. In one case, the channels remove the waste dirty masses, and in the second they contribute to the flow of clean streams outside. Supply systems rarely do without filtration barriers and installations that provide primary air purification, eliminating the same pollution. But there are also special versions of such equipment, which provide for a deeper preparation of the injected masses. In particular, the inlet chamber allows not only filtering the air, but, if necessary, ensuring its heating. Accordingly, the installation has a special design, as well as special installation requirements.

The design of the inlet chamber

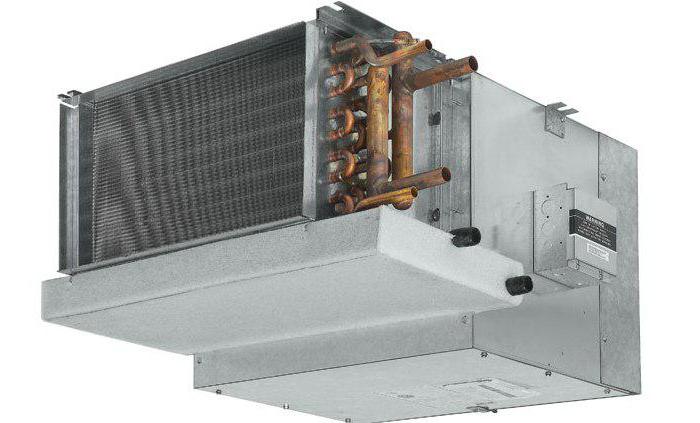

Installation is formed by several functionalparts and components forming the frame. The active work items include: irrigation chamber, heater section, receiving section, insulation valve, etc. This infrastructure is designed for organizing several stages of processing air masses in accordance with the objectives. In addition, the supply and exhaust chamber may provide for the possibility of disassembly in case of movement. Transportation is subject to the condition that separate sections are provided with special protection. As for the case base, it is usually formed by metal panels. Depending on the modification, manufacturers use steel sheets with different treatments. Among the basic conditions for durable operation of the ventilation duct, it is possible to distinguish the presence of a galvanized layer, which protects the camera from rust.

Ways to organize sections

To begin with, it should be noted that the sections themselves inThe camera may have different purposes. According to the method, devices usually allocate configurations of connection with the main and backup fans. Actually, in simple models, additional functional components are not used. Such a solution is common in installations that serve large enterprises, where large air flows pass. In addition, the inlet chamber is supplied with sections of the heater, which can also have different designs. In particular, sections with lateral channel placement, with a central bypass output and with a combined withdrawal line are common. In addition, each section can have several heaters. The choice of a particular configuration of the arrangement and arrangement of the sections is ultimately determined by the requirements for the installation capacity and the staff’s requests for maintenance.

Preparing for installation

Preparatory activities consist ofseveral stages, including the foundation of the foundation and check components. The foundation is carried out according to the type of tie. A 10 centimeter layer of concrete is usually formed, on which the inlet chamber is subsequently installed. Ventilation should be mounted only on a flat surface - the quality of work of the functional parts will depend on this, among which is the heater unit.

Usually the assembly is made on the site of the future.operation. Component parts are unpacked and laid out by type immediately before installation. Next, you should perform slinging sections for the eyes or holes that are provided specifically for this task. In order to ensure that no defects are detected during use of the structure, when it is no longer possible to correct them, the inlet chamber should be checked for technological violations, deviations in the size of individual modules, etc.

Installation of a typical supply chamber

Начинается работа с монтажа приемной секции на hosted foundation. During installation, it is important to consider the nature of the junction of the chamber to the side of the air intake module. Next, you can begin to install the complex with insulated dampers. Depending on the design of the camera, it may be necessary to mount the adapter at the beginning of this operation. It must be adjusted in advance and adjusted to the wall thickness. After that, the installation of the inlet chambers goes into the stage of installation of sectional units. The first is usually attached to the heater, and then irrigation and connecting modules. Fixation to the camera is implemented through complete bolts.

Camera automation

Providing cameras with automation systems givesmany advantages. The level of such control may be different, but even inexpensive models of units allow for the possibility of integrating systems with a modern set of automation options. In particular, it can be maintenance of a predetermined temperature, control of the electric motor function, fixation of power surges and overload protection, equipment shutdown at fire safety signals, etc. Obviously, to implement this functionality, the inlet chamber must provide the appropriate management infrastructure. Typically, at large production facilities, this problem is solved by including the supply chamber in a programmable controller system, which is also responsible for the operation of other engineering systems.

Conclusion

In most cases, incoming cameras findapplication as a part of municipal providing industrial facilities. But in the domestic environment may well be useful such a ventilation module. Some modifications are quite suitable for use in technical or business premises, realizing air renewal in accordance with the owner's requests. Another thing is that in this case you will need a rather compact supply-type camera with a minimum set of functions. These units are easier to manage, let alone simplify preventive maintenance. In addition, domestic models, it is desirable initially to complete noise reduction systems, since the work of the unit may be accompanied by strong vibrations.