Drywall is an excellent constructionmaterial that is mounted quickly and almost without much difficulty. Due to its technical characteristics, it allows you to easily create any design of a unique shape. The installation of this material has one nuance that needs to be considered before starting repairs.

Particular attention should be paid to the sealing of joints in drywall. If this work is performed incorrectly, it may lead to the appearance of cracks, as well as shorten the life of the structure.

Positive traits

In the process of interior decoration are usedvarious materials: plastic, wood, etc. But one of the most common options are plasterboard. Due to their properties and characteristics, they have many advantages over other materials.

When working with drywall it is completely unimportant, inwhat condition is the wall and how many irregularities are on it. The installation process of the FCL is such that it hides all the defects of the base. One sheet is enough to cover a large area of the wall, which saves time and resources.

Another indisputable advantage is the fact thatwhen covering the wall when using a profile, and not just glue for gypsum boards, a small gap appears between the wall and the sheet. Here, if necessary, you can put insulation.

On the surface without any particular complexity, you can apply any desired decorative finish. You can stick the wallpaper, just paint the walls or apply textured plaster.

As a rule, when working with drywall nothere are no difficulties. A metal frame is mounted on the wall or a special adhesive for gypsum plasterboard is used. The profile is used more often, since it makes it possible to lay insulation or sound insulation material under the finish. Sheets are attached with screws to the metal frame.

After the work done, there comes a point thatrequires special attention wizard. After mounting the gypsum board between the sheets, a seam is formed. It can be of different thickness. Before proceeding to the subsequent finishing works, it is necessary to perform the installation of drywall seams.

It is also worth considering that if you apply a layerputty without pre-treatment of joints, with time finishing finish will move away and crack. This will spoil the look of the walls and the whole interior. Therefore, when filling the seams should adhere to the established recommendations.

Tool and material

Before starting work, you should prepare a special tool so that in the process of sequential actions there will be no difficulty.

When sealing gypsum joints with your own hands, you will need these tools:

- bucket for mixing putty;

- electric drill;

- special nozzle;

- putty knife;

- grater;

- reinforcing mesh;

- stationery knife;

- roller.

And also need to purchase the necessary material. You will need a special putty for seams, paper tape and mesh for reinforcement.

Preliminary preparation

The process of sealing seams does not cause much difficulty, but requires compliance with certain recommendations.

If you pay attention to the ends of a sheet of drywall, you can see that they are different. The factory seam has a rounded shape, and the elements used are flat.

In some cases, the standard end can alsobe flat. However, you still need to process slices. Gypsum is visible on these surfaces, as well as inside the gypsum plasterboard. To do this, use the stationery knife. It must be held at a 45 ° angle. This tool cuts off the top edges. Formed joint, which is cut. After that, you need to seal the seams of drywall.

Termination technology

Before starting work with drywall it shouldprogrunt This can be done using a roller or a maklovitsy. After priming, it should be allowed to dry, it takes about an hour. During this time, you can prepare the putty for seams. Today the range of such products is very diverse. The most popular and reputable brands are:

- Knauf Fugenfuller;

- KREISEL;

- SEMIN.

In principle, you can use any composition. They all fit in their characteristics and quality standards.

Selected putty mass should be poured intoworking capacity and using a mixer to bring to the desired consistency by adding water. Turns on the drill should be set to the minimum, so that the destructive reaction of reinforcing additives did not occur. This may affect the strength of the mixture. It is also not recommended to mix the old putty with the new mixture. The composition prepared earlier needs to be spent or thrown out. Only after that you can cook a new mass. After preparation of the putty, you can begin to seal the joints of the plasterboard "Knauf" (with the material of another company the work is done in a similar way).

The solution is applied across the seam and rubbed into the depths.It is necessary that the filler fill the joint across the entire thickness. Thus, the seam is filled along the entire length. If it is very large, then the termination is carried out in two stages.

Reinforcement

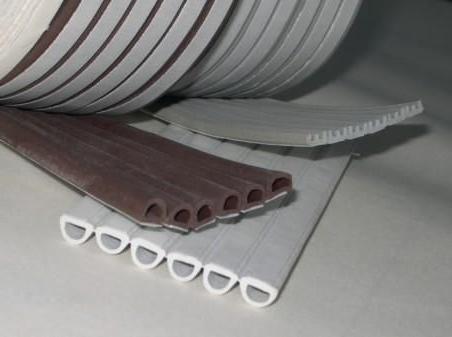

It is worth remembering that you must usespecial tape for sealing joints in drywall, which is made of paper, or fiberglass mesh for reinforcement. Otherwise, the putty will simply fall out or crack in time, since as it dries, it decreases in volume and lags behind the gypsum plasterboard.

During the acquisition of reinforcing mesh needcheck its quality. It can even beginner master. The grid should be checked for stretching, to see how the cells behave. You need to bend it, and then hold it with your hand. If, after such tests, the net has not burst and is not disheveled, then this indicates product quality.

For the convenience of operating its reinforcing meshmade in rolls. It often has one side of self-adhesive, as well as different lengths and widths. When sealing the drywall seams on the copiously applied layer of putty, a grid is applied on top of it. Then, with a strong spatula movement, it is rubbed into the solution that has already been applied.

After that, the mesh is immersed in a putty andreinforce it. Because of this, it does not shrink when dry. Next, you should align the base with a spatula so that there are no tubercles. Then the work surface should be completely dry. After that, you can make further plastering GCR.

Grinding

The final stage is the grinding of the plastered plasterboard sections.

Для этого можно использовать наждачную бумагу.But it will be more convenient to grind the surface with a special grater in which the mesh is installed with the desired cell size. Then the work will be easy and high quality. It should be remembered that the surface should be ground after the mortar has completely dried after the installation of the drywall joints with serpyanka. Grout should be done in a circular motion.

Expert Reviews

Experts recommend using GCRapply the appropriate type of putty to seal the drywall seams. And also it is necessary to adhere to the technology of consistent work to obtain a quality result for many years.