Currently, construction technologies are activelydevelop by offering consumers new and interesting solutions. One of those is a polycarbonate roof. It is ideal for homes, verandas, gazebos and other structures where you want to create natural daylight. At the same time, despite its ease, it is quite durable.

This name is polymer material.It is characterized by resistance to mechanical stress and temperature extremes, as well as high heat and sound insulation performance due to the presence of small air chambers. At the same time it is lightweight and easy to process. These indicators provide easy installation of the material. The roof of polycarbonate does not delay the snow, if it is made at a sufficient angle. Also, it will serve for many years, since the term of the warranty operation of the material can reach 20 years.

Which to choose?

You should not get thin polycarbonate forthe roofs. The price for it is lower, but it is able to withstand smaller loads, and the thermal insulation properties are worse. If we compare 9 mm and 16 mm material, then their indicators differ significantly. Thus, their impact strength will be 2.16 J and 5.6 J, respectively. As for the heat-insulating indicators, they will have a heat transfer coefficient of 3.2 and 2.3 W / m2 * C. But the similar difference in characteristics results in a solid price difference. A polycarbonate sheet with dimensions of 1200x6000 mm and a thickness of 9 mm will cost about 4 thousand rubles, and 16 mm - 6.5 thousand rubles. If you want to make the roof more durable, then some manufacturers can offer products with a thickness of 25 mm and even 32 mm. Their strength and insulation performance will be even higher.

Из данного материала можно сделать практически any design. The roof can be flat, with a slope, in the form of a dome, a prism, a pyramid, etc. But in any case, the material should be mounted on a previously prepared frame. It can be made from:

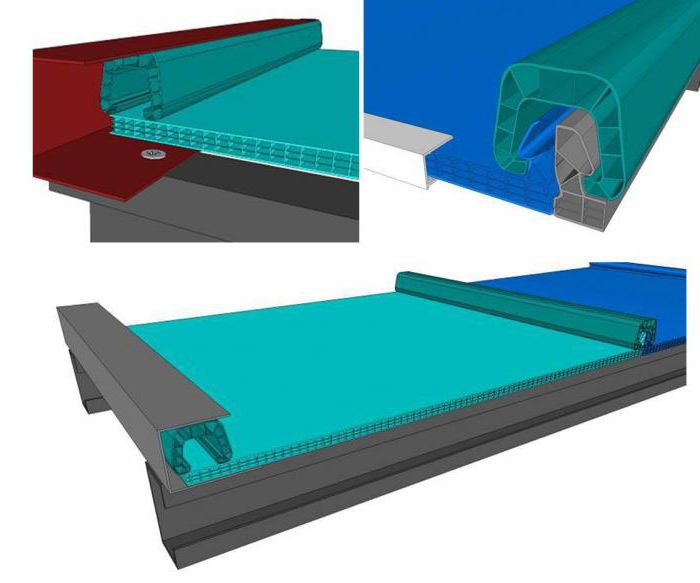

- Metal profile. Both steel and aluminum structures can cope with this task.

- Polycarbonate profile.In terms of structural strength, they are almost as good as metal counterparts. But at the same time they have a number of advantages. They are lightweight, hermetic and transparent. This means that the polycarbonate roof will have no visible connection lines. That is, it will be completely transparent.

If the frame is made of metal profile,then the end sides of the polycarbonate should be taped. This is necessary in order to avoid the accumulation of water and dirt in them. If polycarbonate systems are used, then for these purposes a perforated tape is provided, which reliably covers the longitudinal grooves.