If you will be equipped with a roof frompolycarbonate for the terrace, it is necessary to provide for the design features of the system. In the role of materials for profiles, as a rule, PVC, aluminum or steel is used. The first option is used for small spans, the second is suitable for medium and small, while the third option is great for large spans.

Positive traits

If you decide to choose polycarbonate inquality of the material, you can count on a low specific gravity, which will vary from 0.7 to 4.8 kilograms per square meter. This feature allows you to equip a fairly lightweight design, implement all sorts of ideas designers, without spending a significant amount of money. Such systems have a high load-bearing capacity, as well as flexibility. The last characteristic allows to form arched constructions. After the work, you can expect that the roof will last for 12 years and more, the period of the life of the system will depend on the correctness of the technology, as well as operational characteristics. Such roofs have excellent resistance to chemical influences, and also are characterized by low flammability.

Features of the roof made of polycarbonate

If you will be equipped with a roof frompolycarbonate for the terrace, then when laying the material you need to take care of the supporting structures. Mounting a strong and rigid frame, you provide the roof with reliability and durability. To use thick bearing beams it is not necessary, there will be enough blanks, the cross section of which is equal to 60 x 80 or 60 x 40 millimeters. The rafters should be fixed in increments of 1.01 meters. This figure corresponds to the dimensions of the polycarbonate cloth. As the minimum angle of inclination are 5 degrees, the most suitable slope, which provides the removal of water, protrude 10 degrees or more.

Preparation of materials and tools

If you will be equipped with a roof frompolycarbonate for the terrace, it is necessary to prepare sealing rings, drill, screws, as well as a marker pen. In carrying out measurements, one can not do without roulette. In no way do without a screwdriver during the installation, this tool will complete the manipulation in a shorter time. Stock up with sealant and profiled polystyrene.

Features of mounting polycarbonate

The polycarbonate roof for the terrace shouldmounted on a specific technology. First you need to make measurements, and after marking the covering material in such a way that the linens can be overlapped. The width of the approach of one sheet on the other should be equal to 1.5 cm. The cut line must be marked with a felt-tip pen. The next step in the polycarbonate is to drill holes in which the screws will be installed. Their diameter should be greater than the diameter of a 4-mm screw. Next, the master must install the screws, fixing the plastic on the roof. Eliminate damage to the material will allow an approach in which it is necessary to limit the mechanical effect on its surface. During installation between the wall and the roof, it is necessary to install plastic caps, as well as o-rings. For additional compaction it is necessary to apply profiled polystyrene foam. With a slight slope of the roof, the space under the overlap must be filled with sealant.

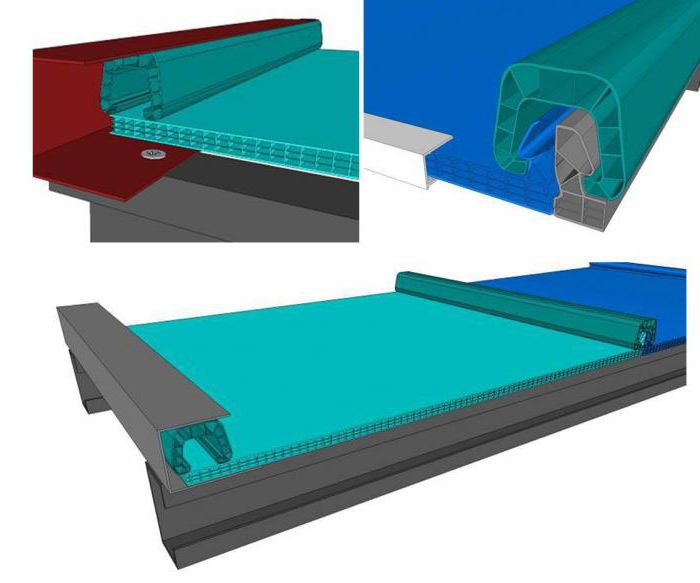

The method of fixing polycarbonate through profiles

If you will be equipped with a roof frompolycarbonate for the terrace with their own hands, it is necessary to fix the connecting and end profiles on the rafters, the dimensions of which must correspond to the polycarbonate cloths. Plate stoppers should be installed with some deviation from the edge of the profile by 20 millimeters. Cloths must fit in the grooves of the profiles. The gap between the sheet and the profile should be equivalent to 5 millimeters or more. This is required in order to provide the compensation distance that will be required for the temperature expansion of the material. The plates must be fixed by attaching the profile, then remove the protective film by installing the plug in place. With the correct installation, it is necessary to apply the sealant exclusively to the joints of the supporting structures and the roof.

Selection of canopy material

If you form a roof ofpolycarbonate for the terrace, the photo is recommended to be considered even before the beginning of the work. However, it is important not only to observe the technology, but also to choose the right material. This is due to the fact that when you purchase unnecessarily thin cloths, you will need to install a more frequent crate. While the most durable sheets will also entail additional costs. Having visited the store of building materials, you should take into account that it is first of all necessary to pay attention to the thickness of the material. Thus, if the canvas have a thickness of 4 millimeters, they are intended for the arrangement of greenhouses and greenhouses. The polycarbonate roof for a terrace, the thickness of which varies from 6 to 8 millimeters, will be an excellent canopy. If there is a need to build noise barriers, then a 10 mm sheet should be used. It is used in the construction of vertical surfaces. The thickest sheets are those that have a thickness equivalent to 16 millimeters. Such sheets have increased strength. They are used for the construction of large areas of roofs. Important and a shade of cloths, it must match the exterior of the main building. Blue and green panels that have medium transparency are used as canopies for swimming pools. While the cherry and brown shades of the canopy are excellent for picturesque areas, on which there are many green spaces.

Canopy Design

If you will be equipped with a roof made of cellularpolycarbonate for the terrace, then, first of all, it is necessary to carry out the design. It is necessary at this stage to take into account the climatic features of the area and the expected loads that will be created by external factors. For the installation of sheets, the thickness of which does not exceed 8 millimeters, it is necessary to pre-equip the frame, between the elements of which a distance in the range from 600 to 700 millimeters should be maintained. When using heavier fabrics, the longitudinal steps should be kept at a distance of 700 millimeters, with regard to the location of the transverse components, the distance between them should not exceed 1 meter. It is important to properly prepare a platform for the roof, for this, along the perimeter with a step of 1.5 meters you need to dig holes, using a garden drill for this. This is necessary for the installation of support posts, in which the role most often used wooden beams or steel supports.

Features of installation of support racks

Monolithic polycarbonate roof for terracerequires the presence of support racks. It is necessary to cut them into the soil by 50-150 cm. It is necessary to level the position of the elements with the help of a building level, only after that it is possible to make concreting. If you decide to use wooden beams as a support, then the lower part of them should be treated with bitumen or a special protective compound, which will prevent decay. If you will be equipped with a roof polycarbonate for the terrace, reviews must be read. Thus, the house masters wait 2 days until the pillars are lowered, and the solution will gain strength. After that, you can get rid of the top layer of the soil, whose thickness is 20 cm. The bottom of the pit should be covered with a pillow, which can be made of sand or crushed stone.