The widespread use of polycarbonate in variousareas made possible by the unique characteristics and aesthetic data of this material. At installation of products from polycarbonate it is necessary to consider some features of this material. In order to maintain the performance of the panels, it is necessary to select the fasteners correctly. How to choose the right washer for mounting polycarbonate, as well as how to install, tell this article.

Properties and distinctive qualities of polymer plastic

- The material has high strength and requires processing with high-quality tools.

- Thermal washers for mounting polycarbonate should be resistant to corrosion.

- When working with plastic, it is necessary to take into account its high coefficient of thermal expansion. Rigid fixation can cause the sheet to break in the cold and swell in the heat.

- Fastening elements should not degrade the appearance of the structure.

Fasteners

The best option when installing a polycarbonate structure is to use a thermal washer, with which it is possible to solve the following problems:

- strong and reliable fixation of the web to the supporting structure;

- sealing holes drilled in polycarbonate to install washers, which prevents the ingress of dust, liquid and cold inside the structure;

- polycarbonate and the material from which heat washers are made expand and contract simultaneously;

- color assortment makes it possible to choose fasteners in the color of the design itself.

What are thermo washers used for mounting polycarbonate?

The material for the manufacture is:

- stainless steel (service life is unlimited);

- polypropylene (service life - 3-4 years);

- polycarbonate (will last up to 20 years).

Thermo washers for fixing polycarbonate fromStainless steels are used to fasten sheets of large size and in areas with strong winds on metal supporting structures. The fastener has a round shape with a small recess in the middle and a hole in the center. A polyurethane gasket is inserted into the recess. For reliable fastening the distance between the washers is 25-30 cm.

Today, fasteners are in great demand,which washer plastic. Although mounts polypropylene exposed to ultraviolet radiation, which destroys the material within a few years. As a result, the canvas begins to vibrate and may collapse. The advantages include low cost, aesthetic appearance and wide color gamut. Produced and transparent products.

The most popular are polycarbonate universal washers, especially when mounting transparent sheets. Such fasteners:

- durable due to special treatment from exposure to ultraviolet radiation;

- harmoniously combined with the main material and almost imperceptible;

- they do not collapse and do not change their physical properties with temperature drops;

- due to the fact that the washer is flat, it is tightly attached to the sheet without damaging it.

Manufacturers produce thermo washers with a leg (selected for a specific sheet thickness) and without a leg (are universal).

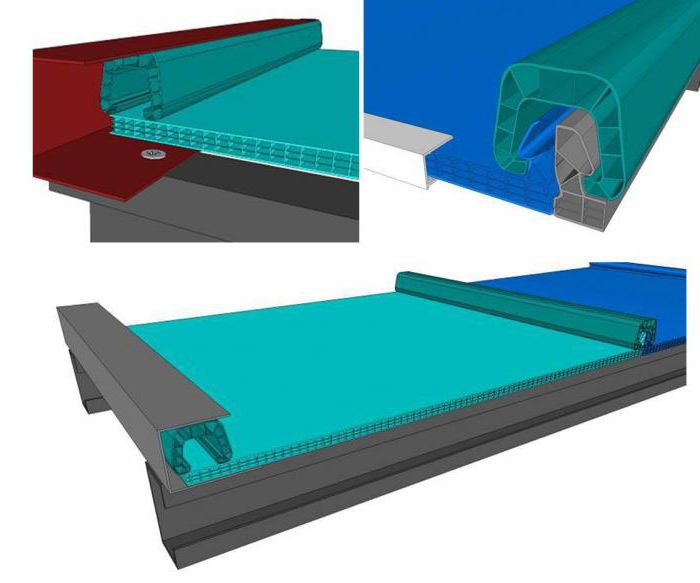

The thermo washer consists from:

- proper washers with or without leg;

- sealant (polymer ring);

- covers (copper or plastic washer);

- self tapping screw (usually sold separately).

Polycarbonate mounting rules

- When drilling holes for thermal washers inthe plastic and the supporting structure of the tool is installed strictly perpendicular. A hole drilled even at a small angle will cause a leakage and crease of the panel.

- Only sharp drills are used, preferably with central fixation (a drill on a tree will do), which will not slip off and will not damage the canvas.

- The hole for the thermo washer is made a couple of millimeters more than the thickness of the screw stem, taking into account the possible deformation of the plastic under the influence of heat.

- Use only stainless steel screws with a cap.

- During installation, the seal should be firmly pressed against the surface of the polycarbonate, but not pressed.

- The distance between the thermal washers is from 25 to 70 cm, depending on the size of the structure and operating conditions.

Which thermo washer is better: with a leg or universal?

Many believe that due to such an element asthermo washer leg, more reliable sealing is achieved, the chance to “pinch” the sheet with a self-tapping screw is reduced (the abutting leg interferes) and the risk of “leaks” is reduced. It should be remembered that usually polycarbonate itself and thermal washers for it are produced in different places, therefore tolerances on sheet and plastic thickness can have discrepancies of about 1 mm. Due to this, there may be conditions for the occurrence of leaks in all attachment points.

Experts advise when using universal thermo washers slightly "pinch" fasteners. In cold weather, “clamping” is compensated for by reducing the thickness of the polycarbonate sheet.