To set the car in motion, it is necessarytransfer torque from the engine to the box. For this is responsible grip. It is this node that transmits the torque through certain gears to the wheels. The main function of the clutch is the temporary detachment of the power unit from the gearbox. Also, the mechanism is responsible for the smooth start of gear units when the engine is running.

Device Feature

Clutch prevents cuttingchange of load, which ensures a smooth start of the car from the place. Also, the clutch protects the entire transmission from loads of inertial moments, which arise as a result of a sharp slowdown in the rotation of the crankshaft on the running engine at the moment when the driver changes gears.

Below we look at the master cylinder device.clutch "Gazelle" is a commercial vehicle, therefore it periodically requires maintenance. What problems happen with the clutch, how to repair, maintain and, if necessary, change this node? Let's tell about everything in order.

How is the hydraulic drive "Gazelle"

It consists of a small number of parts andknots. Thus, the system has a clutch master cylinder. "Gazelle" he completed with 1995. The tank contains brake fluid, which works in the drive. The site also includes the master and working cylinder, tubes, hoses and nozzles. The system also has a return spring.

The principle of operation of the hydraulic drive

If you do not go into details of how it worksclutch master cylinder, "Gazelle" works as follows. When the car driver presses the pedal, this force is transmitted to the main drive through the rod. Here it is perceived and through the network of tubes goes to the working cylinder. The latter, by means of the clutch fork and the release bearing, disconnects or connects the engine to the transmission.

Hydraulic drive unit

Among the main nodes that are included in the design of the element, you can select the pusher. With it, the pedal communicates with the mechanism. It is also the cylinder itself, the piston, the plugs and the return spring.

In the lower half is a working area.In the normal initial state, the piston of the cylinder is compressed by means of a spring against the wall, which divides the cylinder into two zones. There is a gap between the piston and the pusher. Due to it, the liquid enters the working part. When the driver presses the pedal, the pusher moves and closes the gap. Liquid can no longer flow from the upper zone to the lower. The piston moves and force is transmitted from the driver’s foot directly to the slave cylinder.

When repairs are required to the clutch master cylinder

Gazelle may require repairs in case of leaksfluid or air entering the system. Even with the simplicity of the cylinder design, problems also occur with it. There are several faults. Details about each of them - below.

Fluid leak

Repair may be needed if detectedlack of fluid. Causes can serve as breaks or damage to the cuff of the cylinder, a violation of the tightness of the connections. In this case, it is recommended to check whether the level in the expansion tank is sufficient. If the fluid is low, then it is topped up. Then periodically check the level during maintenance work or technical inspection. Sometimes a simple topping up of the working fluid may not help. Then conduct a thorough inspection, identify the leak and then ensure the tightness. In this case, you can not repair, but simply change the clutch master cylinder on the "Gazelle".

Air in the system

Another common problem is air insystem. Such a problem can lead to complete failure of the node. The clutch will not squeeze out completely, and the pedal will be accompanied by a characteristic crunch or vibrations on the gearshift lever. Among the reasons for which air enters the system and directly into the cylinders, it is possible to distinguish various destruction of hoses, natural wear of parts. Do not exclude leakage of fluid in places where parts of the hydraulic drive are connected. How in this case is the repair of the clutch master cylinder? "Gazelle" is placed on a flat surface, replacing damaged hoses with subsequent pumping of the system.

Pumping fluid through the cylinder

There is also another malfunction - in thisIn this case, the cylinder can pump the working fluid through itself. The cause of the malfunction is the cuff, which is most likely damaged. Perhaps there is a development due to natural wear of the piston.

If the first signs of cylinder faults are observed, the clutch system should be diagnosed and serviced. This will help avoid the need to completely replace the cylinder.

Partial repair of the master cylinder with a repair kit

With it, you can avoid the need to replace the site completely. The repair kit consists of the following parts:

- Protective cap.

- Retaining ring.

- Piston.

- Recoil spring

- Cuff of the main cylinder of coupling of "Gazelles".

To disassemble the cylinder completely, it is looking for a special cork. It is necessary to unscrew. During the assembly process, a gasket must be installed under this plug.

Dismantle and defetka

First of all, remove and disassemble the cylinder. You can find it in the left rear corner under the hood of the car.

Далее проводят замену изношенных комплектующих, which are provided in the repair kit. Before you assemble the clutch master cylinder, “Gazelle” is required to put on the emergency brake. Every detail must be lubricated with brake fluid. On the surface of the piston that will contact with the pusher, put a little grease. Next, the cylinder is collected, set in its place and pumped.

Clutch Master Cylinder Replacement

Gazel requires this operation for the samereasons as in the previous case. These are leaks, normal wear, improper operation of the clutch mechanism. As already noted, this cylinder is located on the left rear corner under the hood of the car.

Before the replacement is performed, it is necessary to drain the brake fluid from the system. For this purpose, the hose is connected to a special fitting. The latter is on the working cylinder.

When the working fluid supply tube from the mainthe cylinder will be disconnected, you can begin to loosen the two nuts that hold the clutch master cylinder itself. "Gazelle-3302" continues to stand on the handbrake. After the nuts are unscrewed, the cylinder can be removed and a new one replaced in its place. The installation process is performed in the reverse order. After assembling the system, it is necessary to pump the drive.

How to remove the air?

After any repairs of the hydraulic partclutch system must be pumped. To do this, the liquid is poured into the tank literally to the brim, and the fitting must be unscrewed until it stops. Next, several times press the pedal. This is done so that the brake fluid gets into all the tubes. Then the pedal is fixed. Further tighten the fitting and again squeeze the pedal several times, and then fix it. Next to the fitting put on the tube. It is dipped in a bottle of liquid. The fitting is unscrewed to deflate the air. All these steps need to be repeated until there is no air left in the system at all.

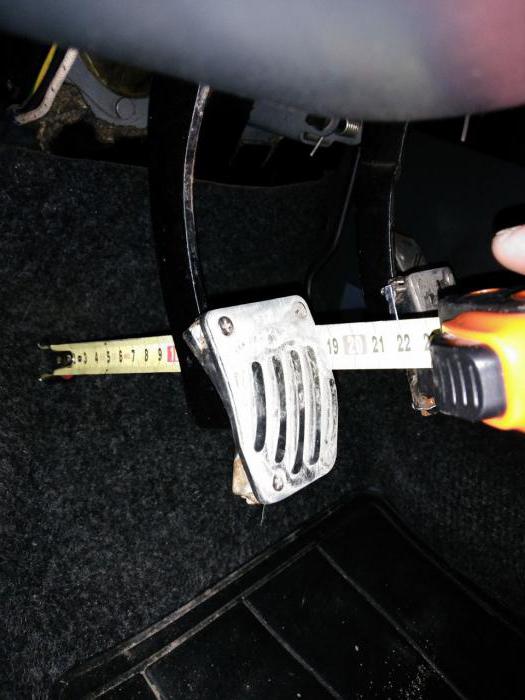

Pedal adjustment

После того как отремонтирован или заменен на The new clutch master cylinder, the Gazelle, requires pedal adjustment. This is a simple process. This operation requires a ruler, but the first thing to do is to diagnose. If, when trying to start driving, the pedal drops, various sounds are heard in the switching process, shocks and jerks are observed when driving, you must start the engine, release the clutch slowly and try to move smoothly. If the car is in no hurry to get under way, then this suggests that the pedal is set incorrectly. Her turn more than it is determined by the norm. Next, using a ruler to measure the distance from the floor to the pedal pad. It should be no more than 14-16 cm. If it is higher, then the pedal must be adjusted. To do this, under the hood should find a bolt with locknut. It is located where the cable ends. The nut tucks. When this is achieved the desired pedal stroke. To increase the stroke, the nut must be tightened. If the move needs to be reduced, it is unscrewed. After adjustment, the pedal is checked again. Re-measure the distance with a ruler. Tuning continues until the desired result is achieved.