In February 1967, from the conveyor KamskyThe first KamAZ cars came off the automobile plant. The characteristics of the new car contributed to the development of the model range. Later on, based on this car, many modifications of the model with different characteristics were created. So, in the light came out truck tractors, dump trucks, lengthened on-board trucks. All models of this family cars were similar in design, and most of the parts and mechanisms were interchangeable.

Equipment

The overall configuration of KamAZ is inherent to alltrucks of those times. A spacious three-seater cab is located directly above the power plant. To access the motor, the cab is tilted forward using a torsion mechanism.

With the development of the automotive industry, the KamAZ car was also modernized, the characteristics of which grew with the use of new technologies.

The car changed in terms of appearance, and in terms of technical equipment.

Transmission. General information

The truck is equipped with a two-disc mechanismcoupling with the radial arrangement of the springs. Clutch release due to hydraulic drive with pneumatic booster. The engine is paired with a five-speed gearbox, with a divider of pneumomechanical control. Transfers from the second to the fifth have synchronizers for smooth switching them on. Transmission of torque from the power plant to the drive is carried out by two cardan shafts.

Arrangement of the mechanism of coupling

For the automatic installation of the middle leaddrive to the neutral position at the moment when the clutch is turned off, there is a special device that does not need adjustment during operation.

The structural features of the casing help to fix the release springs.

There is a clutch of the car from the crankcase, a clutch disc with a metal casing, squeeze springs and levers, two clutch discs with clutches and a neutral driver.

The KamAZ clutch basket is installed on the flywheel with mounting pins and bolted.

Leading, pressure and neutral wheels are equipped withfour levers entering the grooves on the flywheel which transmit the torque from the motor to the contact plane of the driven elements mounted on the splines of the box shaft.

Pressing springs are placed between the metal housing and the squeeze disk.

The element of the levers installed on the middle disk and the drive places them in a neutral position at the moment when the clutch is not engaged.

Shutdown mechanism

The element consists of squeezing arms (levers),located on the pressure plate, the turn-off fork, which is installed on the shaft, in the clutch housing. Couplings of deenergizing of coupling with the rolling bearing of a persistent type.

Drive unit

Components:the drive pedal, the KamAZ master clutch cylinder, the fluid reservoir, the pneumohydraulic amplifier, the tubes for supplying liquid from the cylinder to the amplifier and providing air to the amplifier from the pneumatics.

The capacity of the fluid reservoir is 380 cm3.

The drive amplifier is designed to reduce physical effort when the pedal is depressed. It is mounted on the flange of the clutch housing, on the right side of the power unit.

Process of adjustment of coupling

The adjustment of the KamAZ coupling is made in several stages, in strict compliance with the order and with the use of tools and measuring instruments:

- Installation of gaps between the squeeze disc and cams of squeeze paws.

- Adjust the free pedal press.

- Adjustment of clutch drive.

- Adjustment of the adjustment of the pusher of the amplifier.

Repair of KamAZ, and in particular adjustmentCoupling, as a rule, is carried out in cases of replacement of certain damaged and worn out elements of the mechanism. Or after installing the entire mechanism on the engine. To ensure the synchronous action of the release tabs and their correct mounting position relative to the pressure plate, it is necessary to check the position of the stop ring of the tabs.

As already mentioned, the clutch adjustmentKAMAZ occurs in several stages: checking the distance between the piston of the working cylinder and the pusher, setting the idle travel of the clutch release lever.

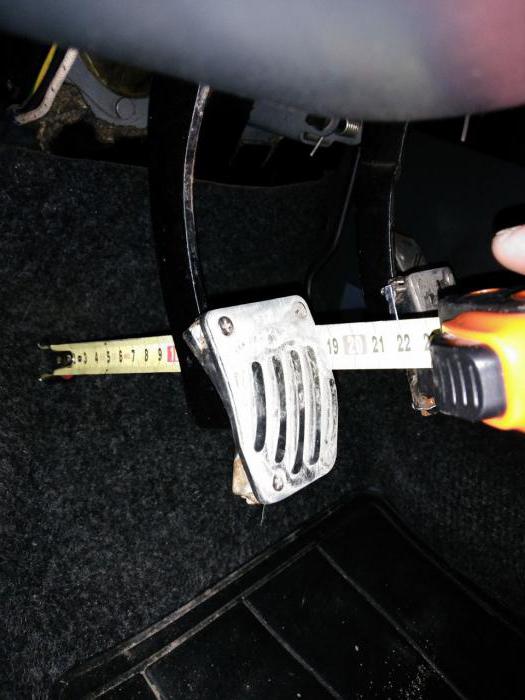

The clearance between the piston of the cylinder and the pusheris set using an eccentric screw that connects the pedal to the pusher, at the moment when the pedal is in its initial position. When turning the adjusting screw, it must be ensured that the movement of the pedal from the stop until the moment of contact between the pusher and the piston is 6-12 millimeters.

Using a spherical nut located on theend of the rod, adjust the free movement of the clutch lever. To do this, the control nut is released and, already rotating the spherical nut, adjust the distance between the rod stop and the lever to a size of 3.1-4.7 mm.

After carrying out these adjustmentsthe total free movement of the foot pedal must be 30-42 mm. And if the clearance is correctly set in the clutch drive, the movement of the amplifier stem should not be less than 24 mm.

Check of work of the mechanism

After carrying out these repairs,to check the efficiency of the mechanism as a whole on the engine. If the adjustment of the KamAZ clutch is carried out correctly, switching gears will occur without a characteristic crack in the box area and without any difficulties.

If the repair of KamAZ is of poor quality, thenthere is a possibility of slipping clutch, which quickly disables the friction linings of the discs and release bearing. In this case, it is difficult to switch gears on until they are completely inaccessible.

Process Features

Adjustment of the clutch of KamAZ is carried out ona special technological line of maintenance by qualified mechanics with the use of special equipment. Only in this case it is possible to achieve a high guarantee of serviceability of the clutch.