When building houses and other buildingsDestinations today are made to use various materials, including blocks made of gas, foam, claydite and gas silicate. Before using one of the listed materials, it is recommended to become familiar with the technology of masonry walls.

Work on the laying of lightweight concrete products

Each master before the start of manipulations beforelaying walls must know how the formation of corners, the alignment of products, as well as what the technology is. First you need to shut the solution and bring it to the point of work. Most often, a cement to sand ratio of 1 to 4 is used for this material. However, it will all depend on what kind of cement you plan to use for masonry.

Methods of work

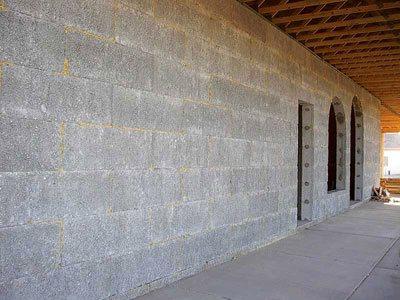

Masonry walls of claydite blocks with their ownhands involves the formation of seams, the width of which should be equal to about 1 centimeter. When installing the first row, you need to carefully monitor the alignment of products vertically and horizontally, in the future this will allow you to get an even styling. All horizontal and vertical seams must be necessarily greased with mortar to prevent gaps.

Window hole

Laying near the window opening should bemade strictly horizontally and as carefully as possible, this is especially important for an aesthetic look. In this case, using only the construction level to check the correct location of products will not be enough. You need to prepare a plumb line, which is a homemade device made of thread and heavy object. This will determine how correctly the product was vertically displayed.

Advice of specialists

Provided that the laying of the walls of the blocksit is made independently, then after the first row will be ready, it is necessary to tighten a usual cord which will act as a level for laying of other blocks. The rope must have good tension, while it is necessary to eliminate its sagging in the middle.

Masonry needs to start from the corners.Only then can the master proceed to the formation of the walls. It is important to observe the dressing of products with the previous row. The minimum distance between the vertically oriented seams in the vicinity of the rows located can be equal to the limit of 10 to 20 centimeters.

Reinforcement of block walls

The laying of the walls of the blocks should suggestreinforcement, using reinforcement. To do this, stock up with masonry mesh or rebar, whose diameter is from 6 to 10 millimeters. It is necessary to pack these elements every four rows. Some experts advise the use of fiberglass reinforcement, which allows you to save on delivery. Among other things, this material reduces heat loss in the walls. Internal and external walls are advised by experts to lay at the same time as partitions, providing ligation of corners and reinforcement. If it is impossible to do this for a number of reasons, then the strobe must be made for dressing by releasing a reinforcing mesh in those places where the inner wall is then supposed to be laid. On the top of the wall, which is made of claydite-concrete blocks, it is necessary to provide reinforced concrete reinforcement. It is important to take into account that it will have a higher thermal conductivity in comparison with expanded clay concrete hollow blocks. Therefore, the master should provide a place for insulation of this part of the wall.

Tips for laying lightweight aggregate blocks

If you will be laying walls fromblocks, you do not need to do too thin seams in the case when the size of the products is not maintained. The thickness of the seam can reach 10 millimeters, while a thin seam can adversely affect the irregularities of the wall. If you do the work without any help, then before laying each next row it is desirable to expand the blocks on the previous row so that they do not interfere with applying the solution to the surface. This will significantly speed up the process. Laying the walls of the blocks should not assume too much blows to the products to align their position. If we are talking about hollow products, then you can easily damage them, because they are fragile. When carrying out works on laying the walls will certainly need halves of blocks, perhaps even a quarter. If you do not have the experience of breaking products, then it is best to prepare an angle grinder for cutting.

Masonry using gas silicate blocks

Gas silicate blocks are versatile,with their help, you can build internal, external walls, as well as partitions and load-bearing walls. Installation work is prohibited to carry out in rainy weather, as the cellular structure of the products will accumulate moisture, and the temperature difference will lead to damage to the masonry. To prepare the solution, it will be necessary to prepare a plastic bucket, a special nozzle on the drill, as well as a hand-held electric drill. To apply the mortar, you will need a trowel, it is desirable that there are several of them, each of which must have a different width. The laying of the walls of gas silicate blocks provides for their alignment with respect to other products, for this it is customary to use the construction level, a rubber hammer, the last of which can be replaced with wooden ones. To machine the blocks, you need a plane, a tool for making grooves, a soft brush, a saw, a marking square, and drills. In the process of laying you will need a dry glue mix, as well as a cement-sand mortar.

Installation instructions for gas silicate blocks

If you will be laying walls ofgas silicate blocks, it is necessary to waterproof the surface before starting work. To do this, on the site of the future location of the first row you need to lay a layer of roofing material, which is fixed on the cement-sand mixture. Layer of the solution should be laid on top of the ruberoid. It will be located on the first row of blocks. In such a mixture, the ratio of cement and sand should be 1 to 3. This solution can also be used for further laying, but the thickness of the seam should not be more than 20 millimeters. The surface of the block is moistened for better grip if the weather is dry enough. Experts advise the use of special adhesives, as if you increase the thickness of the seam, this may cause additional heat loss.

Technology of work

Методика укладки блоков является такой же, как has been described above. After the corner products are in place, they need to be carefully leveled, and then you can continue to work in accordance with the previously set guides. For external walls, the guides should be installed in advance around the perimeter of the walls, setting the pegs 2 meters apart. A rope stretches between them. If we are talking about an internal partition, the construction is carried out from one of the products of the side walls. In this case, it will be necessary to carry out advance marking on the surface of the floor and walls with the help of a tape measure and level, refusing to install waterproofing. After the side block is installed, special glue will be applied on the side faces of the products. It will be possible to get rid of irregularities on a horizontal surface with the help of a grater, and the remaining rubbish like splinters of blocks or dust should be swept away with a soft brush.

Preparation of gas silicate glue

If you use glue with a good level of adhesion,then you can ensure the minimum thickness of the seam, which should not be more than 3 millimeters. This can be called an undoubted advantage of this material, since you can improve the insulating characteristics of the finished walls. Among other things, the gas silicate adhesive has a sufficiently high strength, which makes it possible to use it when carrying out other works, for example, when laying foam or gas concrete, as well as when finishing the exterior and interior walls with tiles. If you will be laying the walls of the blocks with your own hands, then the adhesive composition can be prepared by pouring water into a plastic clean bucket. After that, the dry mixture is added, the composition is well stirred using an electric drill with a nozzle. Stirring should be carried out at low speed until it is possible to achieve complete homogeneity of the composition. It is important to correctly observe the ratio of liquid to dry mix, which should be indicated in the instructions for the product. Different manufacturers may have this indicator. In order to eliminate the freezing of the composition in the bucket during the work, it is recommended to prepare a small portion. As soon as you start laying the walls, you will be able to understand how much you will be able to work out at the time of hardening. Everything will depend on the speed of the work.

Laying down the next rows

In general, the technology of laying walls from blocks ofdifferent materials does not differ among themselves. As soon as you finish laying the first row, you can proceed to the second. The adhesive should be applied to a horizontal surface with a trowel. After that the first block is laid. The solution is then applied to the side surface of the first product and to the zonal base. The second row should begin to stack from the corner. However, if in the first row the first corner piece began a row with its long side to the right, then in the second row the first block should go with the long side to the left. This will give the whole structure strength. The procedure and technology of laying gas silicate blocks are the same as when working with ordinary bricks. However, carrying out these works is much easier due to the low weight and size of the products.

Foam Block Laying Technology

If you will be laying walls fromfoam concrete blocks, the first row should be laid on the cement-sand mortar, which is applied with a layer of 3 centimeters on the waterproofing surface. Laying the next row should be done no earlier than 3 hours after the completion of work on the first row. At the same time it is possible to use both cement mortar, and on special structure. The thickness of the future seam should not be more than 5 millimeters. Masonry walls of concrete blocks produced by the same method. For laying window openings should use hollow foam blocks that have a U-shape. They should be laid related reinforcement, and then pour concrete. The rods are laid in special channels that are cut in blocks. If there are none, then you can use a grinder or wall chaser for this. Before laying the floor slabs, it is necessary to equip the concrete armopoyas, the height of which should be 20 centimeters.

Кладка стен из керамических блоков тоже produced by a similar technique. You must remember that the cement mortar must be prepared in small portions. If you use a special glue, then it will be necessary to work out within 15 minutes after preparation. The optimum temperature for laying foam blocks is the range from +5 to +25 degrees. If the weather is hot, the foam blocks should be moistened periodically. The laying of walls of aerated concrete blocks must also be carried out with the help of a building level and a plumb line. This is the only way you can provide evenness to the walls. Cement or glue is best applied with a special comb, this will make the seams more even and thin. It will be possible to get rid of the excess solution using a conventional construction spatula.

Conclusion

Masonry technology of ceramsite concreteblocks is no different from the techniques that were described above. In all cases, it is important to take care of placing the products horizontally and vertically, this will ensure future walls with reliability and evenness.