Masonry is a building structure,consisting of bricks or stones, laid on the solution and carrying a load of its own weight and weight of structural elements that rely on it. Masonry is made in a certain order and performs heat insulation and soundproofing functions.

For masonry works are used various types of mortars: cement, lime-cement and lime.

There are such types of brickwork:

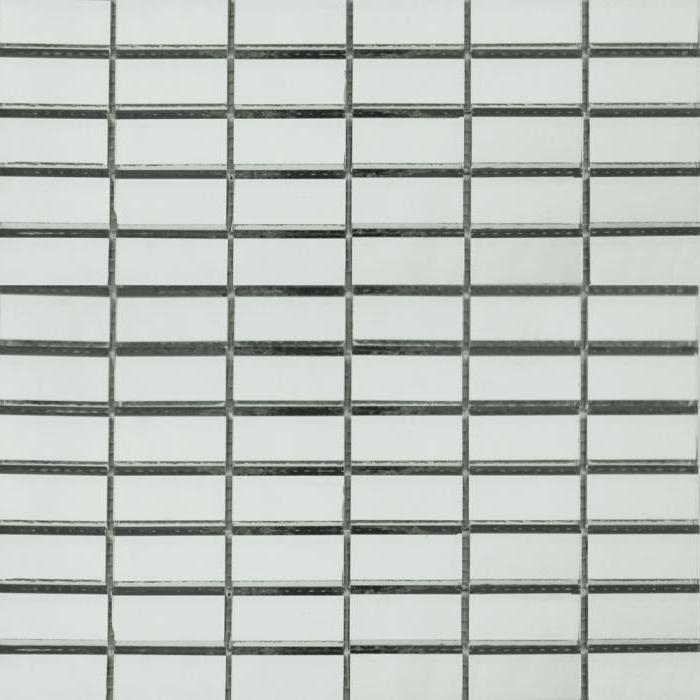

- solid. In this case the masonry has the appearance of a solid, solid monolith;

lightened.In this form, part of the masonry is replaced with a thermal insulation material or has an air layer. The most common types of masonry such as well, brick-concrete anchor, with three-row diaphragms, with internal insulation and with air interlayer;

- Reinforced. Such types of brickwork are reinforced with metal rods or nets. Both longitudinal and lateral reinforcement can be used.

In its form, masonry and brick,mainly, it has the form of a parallelepiped, where all faces have their professional names. So, the largest sides are called the upper and lower bed, it is they who put the stone on the mortar, the short side faces are called tyches, and the long ones are called spoons.

All rows of masonry have their names, so extremethe rows are called versts, on the side of the facade there is an external verst, on the inside of the room there is an inner verst. If there are rows of masonry between the versts, they are called zabutovochnye (zabutovka).

If the row is laid out in such a way that the outside is visiblespoons - a series called a spoonful, if you see tychki - a number of poking. The height of the row of masonry consists of the height of the brick itself and the thickness of the vertical layer of the mortar, which, on average, has a thickness of 1.2 cm. The width of the masonry determines the width of the walls and should be a multiple of half the brick. In determining this, the thickness of the vertical joints is taken into account and, on average, this value is 1.0 cm.

Any type of brickwork must havehorizontal dressing. A bandage of brickwork is carried out by means of a certain laying of stones and is called a dressing system. The system of dressing can be single-row or chain (in this case, the ligation of the brickwork is formed by the successive alternation of spoon and bunch rows), multi-row (five consecutively stacked loopholes are bandaged with one knives) and three-row (three spoon rows are tyed, while in the spoon rows, vertically).

Depending on what plasticity solution is used and what are the requirements for the quality of the front side (under the screed or plaster) in the construction of these methods of masonry:

- Press. Masonry is carried out on a plastic or rigid mortar, the rows can be laid out both spoon and bumper;

- In a nutshell. Masonry is carried out on a plastic mortar, the seams on the front side are not completely filled, the use of a trowel is not required and the surface of the walls requires plastering;

- with the pruning of the solution. Masonry is carried out on a plastic mortar, the seams on the front surface are filled completely;

- half a minute. Used for masonry in the forehead.

The quality of masonry is controlled by workersdrawings and Building codes and regulations. Bricklayer, in the performance of his work, should monitor the correctness of banding the rows, the filling and thickness of the seams, the verticality of the corners and the horizontal lines, the availability and correct installation of anchors and metal bonds, the quality of the surface on the front side - the selection of bricks, observance of its color and pattern, .