Plasticizer S-3 today acts as the most common concrete additive within the Russian market. It is known for its effectiveness and belongs to the first group of plasticizers.

Supplement Features

In the role of the main feature of the described additiveits ability to bring concrete into a state of mobility, in addition, when using it, the construction turns out to be stronger and more durable, and cement can save up to 25% in volume, which is why the use of this substance is economically viable.

Application area

Plasticizer C-3 is used in the manufactureprefabricated structures, which are based on high-strength concrete. Apply the additive and when pouring products that have a large number of valves. This plasticizer is necessary when creating monolithic structures that have a complex configuration, apply it when forming pressure reinforced concrete pipes.

Need to use

Plasticizer C-3 is used if availablethe need to increase the mobility of the solution to mark P-5. Moreover, after the addition of this chemical, the concrete acquires the quality of waterproofing up to W12. Structural strength is increased by 35-40%, which corresponds to concrete belonging to class B45. After completion of the hardening process, the design acquires improved qualities of frost resistance.

Features of use

Пластификатор С-3 отлично сочетается с иными varieties of additives to concrete. This indicates that it can be used in tandem with many anti-frost additives, as well as substances that accelerate or, on the contrary, slow down hardening.

Plasticizer C-3 should not be used inquantity, which exceeds in terms of dry matter 0.3-0.8% relative to the weight of the cement, closed in the solution. Supplement must be entered, after diluting it in water.

If you add a plasticizer in the amount of 0.2-0.7% ofcement content, it is possible to create cast mixtures that are self-compacted and almost do not need a vibration process, whereas if you reduce the volume of water, the concrete will acquire increased strength, and the mobility will remain unchanged. It is permissible to apply both of the described techniques in part, that is, to make the solution of increased mobility compared to the original and simultaneously increase the strength characteristics of the mixture, reducing the volume of water used.

Positive characteristics of the additive

Plasticizer for concrete allows you to getthe front surface of the product or design, which is characterized by increased smoothness, no matter how complex the shape you need to get. After hardening, the concrete, in which a plasticizing component was added to the mixing process, acquires the qualities of enhanced water tightness, as well as corrosion resistance, by 2-4 times. Laying concrete with a plasticizer involves less impressive labor costs. After pouring, the product or structure does not have to be subjected to such lengthy treatment as in the case of a traditional solution, with temperature and water treatment. Stripping time will also be significantly reduced. When using other additives, the plasticizer does not react with them and does not lose its quality characteristics.

Пластификатор для бетона не вреден для здоровья man, during the operation does not emit toxic substances. The Ministry of Health of Russia permits the contact of reinforced concrete structures, which include a plasticizer, with drinking water, as regards the case of the manufacture of reinforced concrete pipes.

Mixing solution with the addition of

In order to prepare a concrete solution, inthe composition of which is supposed to include a plasticizer, the latter can be pre-mixed with cement and sand, which is true if there is a need to obtain a dry sand-cement mixture. There is another way to add a plasticizer, it can be poured in the form of a powder into a concrete mixer with water for mixing. As an alternative solution, a method of pre-dissolving the powder in water is sometimes used, eventually a solution of 15-30% concentration should be obtained. In this state, the solution can be added to the concrete mixer, but this should be done only after the main volume of water has been introduced.

Применение пластификатора С-3 предполагает use of the substance in the amount of 250-700 g per 100 kg of cement component, then it will be possible to obtain a dosage in the range of 0.25-0.7% of the volume of cement. If casting technology is used in the work, the concentration should be equal to the limit of 0.5-0.7% of the volume of cement. Filling this mixture involves filling the formwork or form. The result is a smooth surface that does not involve finishing.

Plasticizer cost

Plasticizer C-3, the price of which is in differentregions may be different, of course, has its drawbacks, but this does not reduce its positive characteristics. It is possible to purchase a plasticizer on average for 64 rubles / kg.

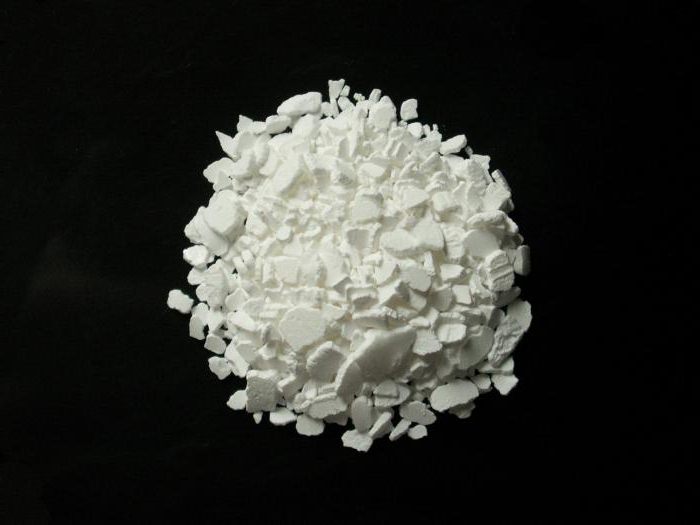

The appearance of the plasticizer

Пластификатор представлен жидкостью, которая has a dark brown tint. In addition, you can purchase and powdered plasticizer, which has a light brown color. The substance is simply dissolved in water. In the powder, the goods are packed in 25-kilogram bags, whereas if you purchase a liquid substance, it will be poured into plastic bottles, the volume of which is 0.5 l. A positive feature in a dry plasticizer is its almost unlimited shelf life. In this case, the only storage condition is the elimination of liquid ingress. Plasticizer C-3, the instructions for use of which have been described above, should be used according to the rules, otherwise the concrete will not acquire the expected qualities of increased strength and resistance to moisture. It is not worth saving and using a plasticizer with over-expenditure, since it will not be possible to get a positive result in either case.