Low temperatures contribute to less rapid hardening of the concrete. Water under such conditions freezes, and hydration of the binder is suspended.

Need to use

For concrete, such processes are undesirable, sohow they adversely affect the strength. As a result, the structure becomes loose, and its frost resistance leaves much to be desired. In order to ensure normal curing at low temperatures, it is necessary to take appropriate measures that contribute to the preservation of water in the liquid phase.

General description of antifreeze additives

Antifreeze additives in cement mortaradded at lower temperatures. They are a liquid that may have a yellowish or light gray shade, and may also be completely colorless. The mixture has a density in the range of 1.4 kilograms per liter. As for the mass fraction of calcium nitrate, it is in the range from 42 to 45%. These characteristics may vary, depending on the type of substance used.

Antifreeze additives in cement mortaradded if necessary, increase the mobility of the composition, which greatly facilitates the process of formation of structural elements. These compounds contain a corrosion inhibitor that protects the bars of the reinforcement from oxidation. After the addition of the described composition, mortar builds strength in a short time, and the water resistance of the material increases.

Method of use of additives in the preparation of the solution

When antifreeze additives are added incement mortar, plasticizer, sand, cement are used in parallel. It is desirable to add the above composition together with water, because the liquid of the antifrosty composition can partially replace the mixing water.

All ingredients are well mixed, in the processWhat should a concrete mixer use? This stage should last for an hour. The result is a homogeneous mixture. The degree of uniformity will depend on the mixing period and the quality of the concrete mixer. The amount of the additive should be equal to the volume that is written on the package. Most often it is 0.2% of the volume of cement by weight. It is important to note that this volume corresponds to the temperature value specified in the instructions.

When antifreeze additives are added incement mortar at home, it is important to consider that with decreasing temperature the volume of the product should be increased. It is important to take into account that 0.05% of the composition corresponds to one degree. The dosage is usually indicated in grams. If this value is specified in millimeters, to determine the amount of the composition it is necessary to divide its mass by 1.45. In the end, it will be possible to obtain the required volume, expressed in millimeters. It remains only to measure the required amount of the mixture, and then enter it into the solution.

Antifreeze additives in cement mortar,The reviews about which are mostly positive are added exclusively at negative ambient temperatures. The use of these mixtures under other conditions is unacceptable. Elements of structures and concrete products should be moistened for two days, this will prevent drying.

Potash consumption

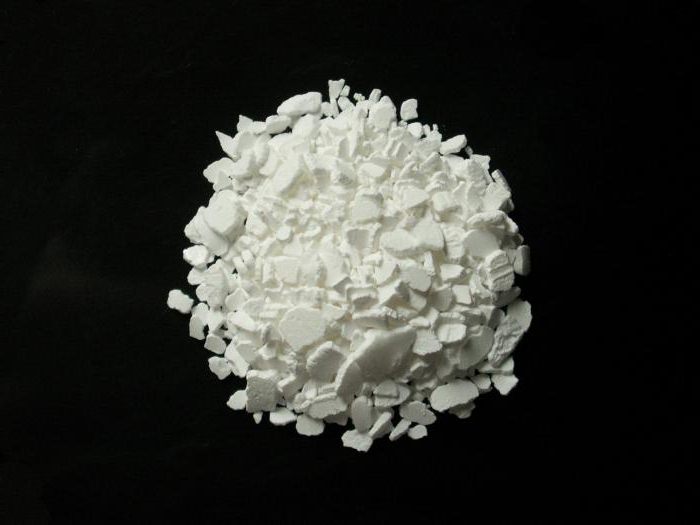

Potash is used in construction in the roleantifreeze additives. It is also known as technical potassium carbonate. You can buy it in the form of crystalline powder, which is characterized by excellent solubility in water. The saturated solution freezes at a temperature that is equivalent to -36.5 degrees. Potash can significantly accelerate the hardening and seizure of concrete.

Characteristics of the composition will be maintained ifDuring the casting process, the concrete temperature will not drop below -25 degrees until it reaches strength. If there is a need to enhance the frost resistance of concrete, then additionally add liquid sodium glass.

Similar antifreeze additives in cementthe solution is introduced, as a rule, to ensure a short period of thickening. At the same time, the process is practically independent of the ambient temperature. Potash acts as a neutral additive that does not affect rebar. When the temperature is lowered, the consumption of the substance increases. Thus, if the mark of the thermometer is in the range from 0 to -5 degrees, then from one to five kilograms of cement you will need from 5 to 6 kilograms of potash.

With a temperature range from -6 to -10degrees antifreeze additive should be used in the amount of from 6 to 8 kilograms per hundred kilograms of cement. Whereas at -11 to -15 degrees, the consumption of potash increases from 8 to 10 kilograms by the same volume of the cement component.

Reviews

According to consumers, antifreezecement mortar additives whose consumption was mentioned above are introduced not only for the preparation of concrete mixtures. Among other things, they can be used in lightweight concretes, in the manufacture of road elements, when mixing plaster solutions, as well as in the formation of a road surface.

In industry antifreeze additivesused in the construction of bridges, buildings for various purposes, oil and gas platforms, dams and other things. With the help of these compositions it is possible to reduce the construction time, and also to reduce the cost of the object due to the rational use of labor and technology. This is very popular with private consumers and professional developers.

Conclusion

If you use antifreezeadditives in cement mortar, salt will be formed together with the products of hydration of concrete. Before using substances with the described purpose, it is imperative that you familiarize yourself with the features and characteristics of the ingredient discussed above.