Vice is called universal devices,designed to hold the workpieces in the course of manual (in this case, the vice is installed on the bench bench) or mechanical (special machine tools are used) processing.

Manufacturers of machine tools offera wide choice of vice of different types. Each species has certain characteristics and has a number of features. Thus, proceeding from the features of the technological process and the existing equipment, it can be concluded that the selection of the vice is a rather difficult task. How to make the right and optimal choice in view of the existing park of machine tools? The article answers this, as well as other questions that may arise when organizing and purchasing equipment for your own workshop.

What materials are made of a vice

Vise housing is made of steel or graycast iron. The most often found are cast iron casings. This is due to the fact that cast iron has very good foundry qualities (the melt stiffens for a long time and has time to fill the entire mold) and is much cheaper than steel. In this case, the mechanical properties of the alloy with increased contents completely satisfy the requirements for materials used for the manufacture of both manual and machine vice.

The market was filled with equipment from China, Europe andAmerica. In these countries, their standards are developed and used. As for the Russian Federation, on its territory the production of such equipment is strictly regulated by GOST 16518-96.

The most important technical characteristics of the vice

When choosing a specific device,carefully familiarize yourself with its technical parameters and capabilities. First of all, in order not to throw money away, it is necessary to find out whether they are intended for installation on what machine equipment (milling, surface grinding, planing, broaching, drilling or other machines).

Потом необходимо проверить, является ли ширина working sponges are sufficient, or they are too narrow and will forcefully press the surface of the workpiece, leaving dents in it. Important is the clamping force. The stroke length makes it possible to determine the maximum possible linear dimensions of the workpiece to be set in the vice.

In the event that the vice is purchased forhobbi machine tool of small sizes, installed in the garage or in the basement of the apartment building, or even on the balcony (there is such a thing!), then the critical parameter, of course, is their mass. Limit on the weight of the product installed on a small hobby machine should not be exceeded, since the mechanical components of such a machine will quickly fail.

Types and types of vice for metalworking

- In accordance with this standardthe industry produces vise of normal accuracy, increased accuracy and precision, equipped with a manual or automatic (hydraulic, pneumatic, electric) drive.

- Depending on the purpose of the vice are divided into manual, locksmith, machine tools, special (with automated drive).

- By type of drive, machine vice is extracted with a manual clamp, with a hydraulic drive, with a lock (or eccentric clamp), with a spring clamp.

- Depending on the material being processed and its mechanical properties, jaws of different hardness and with different notches can be mounted on the vice.

The main elements of the vice

Modern machine tool grip constructivelysignificantly differ from the classical vice. However, the principle of operation and action remained unchanged, and the following main components of the product can be identified: the body, the movable and fixed sponge, the handle, the power screw with trapezoidal fixed thread, the handle.

The features of the vice, installed on the table of the milling machine

Machine milling vices are, perhaps, onevery workplace. And if in the conditions of mass production they are trying to make special devices for fastening the workpiece on a work table, then in the conditions of a single production, as well as repair production, not to mention a garage workshop, such a vice is simply an indispensable thing.

For the vise installed on the machine, the rigidityis the critical and most important parameter. If the structure does not provide rigidity, then during processing, an unpleasant and irritating hearing of the person will cause a loud squeal of the metal. In this case, the milling cutter will jar. As a result - premature failure of a very expensive tool and unsatisfactory roughness of the treated surface. Sometimes a detail can even marry, which means additional financial loss.

If on a universal metal fence the spongehave a characteristic corrugated surface, then on the vice for machine tools they must always be smooth. And rough rough surface after casting is not allowed. Such sponges are processed by a cutting tool (milling cutter or shovel), and then ground on a surface grinder to achieve the desired roughness and geometric shape.

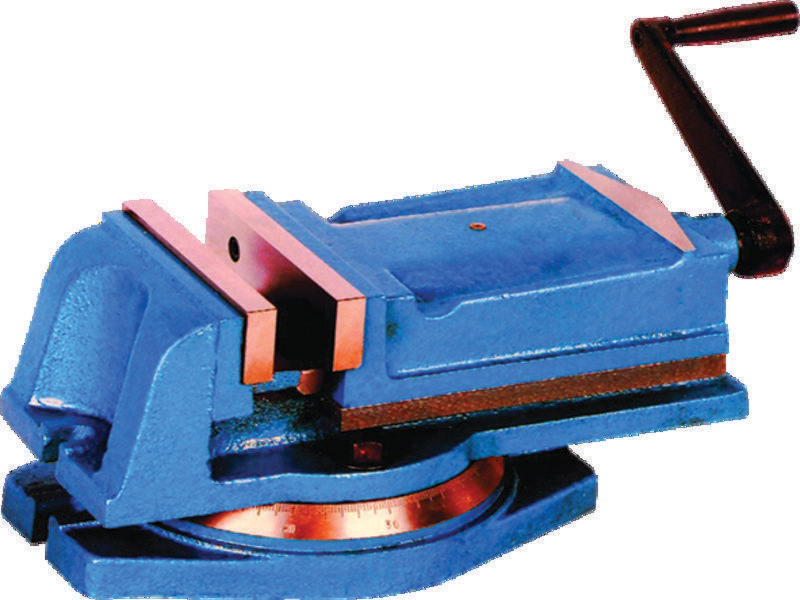

Rotary machine vice

These vices are mounted on a special swivelmechanism. It has no restrictions and can be rotated to any arbitrary angle. To make a turn, you need to unscrew the two nuts at the base. After the desired angle is set, the nuts are clamped with a certain carabiner key with as much force as possible.

The disadvantage of such a vice is the lack of rigidity. But the swivel base can be removed, and then it will be a conventional clamping device.

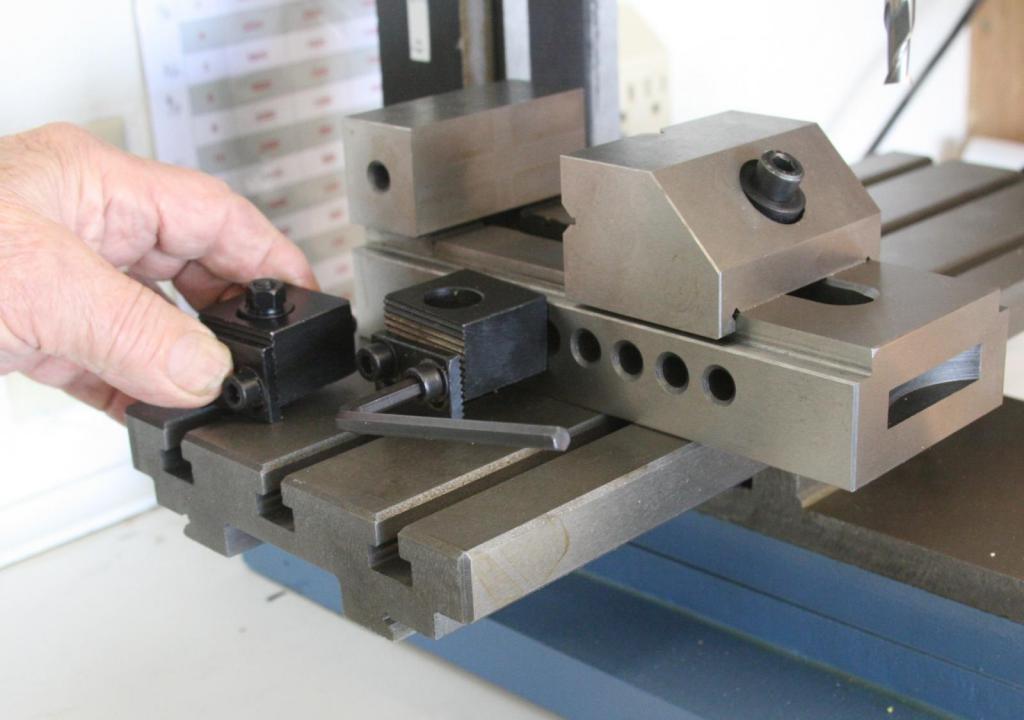

Machine vice for drilling machines

Vice placed on the framevertical drilling machines, should provide the ability to bias the workpiece in two directions in a horizontal plane. This statement is not valid for radial drilling machines, because they themselves move the spindle with a drill installed in it. In general, the vice for machine tools for drilling units has much less rigidity compared to milling machines, since they have many degrees of freedom.