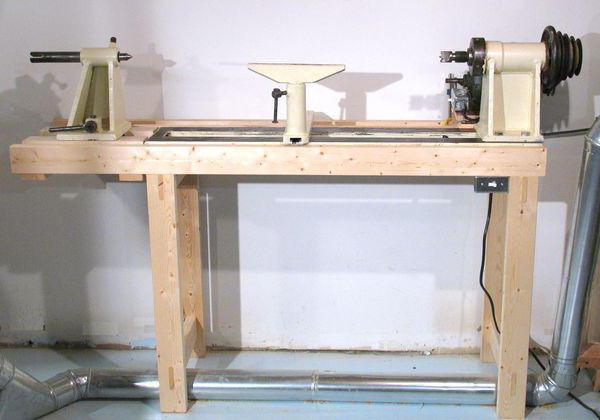

In order to turn the usual workpiece intosuitable part for the mechanism, use turning, milling, grinding and other machines. If milling is necessary for the manufacture of more complex parts, such as gears, cutting splines, then turning is used to create simpler parts and give them the desired shape (cone, cylinder, sphere). Cutting conditions during turning are very important, because, for example, for a brittle metal, it is necessary to use a lower spindle speed than a durable one.

Turning features

In order to carve a certain part onlathe, as a rule, use incisors. They come in a wide variety of modifications and are classified by type of processing, feed direction and shape of the head. In addition, the cutters are made of various materials: alloy steel, carbon, tool, high-speed, tungsten, hard alloy.

The choice of one or another depends on the materialthe workpiece, its shape and method of grinding. Cutting conditions during turning necessarily take into account all these nuances. When turning the workpiece is fixed in the spindle, it performs the main rotational motion. In the caliper is set the tool for processing, and the movement of the feed is made directly to them. Depending on the machine used, both very small and large parts can be machined.

Essential elements

What elements of cutting modes when turningcan processing be used? Despite the fact that turning is not always a very easy operation, its main elements are speed, feed, depth, width and thickness. All these indicators depend primarily on the material of the workpiece and size. For very small parts, for example, the cutting speed is chosen as the smallest, because even 0.05 millimeters that were accidentally cut can lead to a marriage of the whole part.

In addition, very important indicators fromwhich determines the choice of cutting conditions for turning, are the stages at which it is produced. Consider the basic elements and stages of metal cutting in more detail.

Rough, semi-finishing and finishing

Превращение заготовки в необходимую деталь – complex and time-consuming process. It is divided into certain stages: roughing, semi-finishing and finishing. If the detail is simple, then the intermediate (semi-finishing) stage, as a rule, is not taken into account. At the first stage (draft), details are given the necessary shape and approximate dimensions. In this case, be sure to leave allowances for subsequent phases. For example, a blank is given: D = 70 mm and L = 115 mm. From it it is necessary to carve a part, the first size of which will be D1 = 65 mm, L1 = 80 mm, and the second - D2 = 40 mm, L2 = 20 mm.

Rough processing will be as follows:

- Trim the end to 14 mm.

- Thread diameter over the entire length of 66 mm

- Pierce the second diameter D2 = 41 mm for a length of 20 mm.

At this stage, we see that the part was not fully processed, but as close as possible to its shape and size. And the allowance for the total length and for each of the diameters was 1 mm.

Finishing this part will be as follows:

- Perform a fine butt cut with the necessary roughness.

- Thread through the length of 80 mm in diameter 65 mm.

- Finish turning along the length of 20 mm into diameter 40 mm.

As we can see, finishing requires maximum accuracy, for this reason, and the cutting speed in it will be less.

How to start the calculation

In order to calculate the cutting condition, firstturn it is necessary to choose the cutter material. It will depend on the material of the workpiece, the type and stage of processing. In addition, incisors in which the cutting part is removable are considered more practical. In other words, it is necessary to select only the material of the cutting edge and fix it in the cutting tool. The most advantageous mode is the one in which the cost of the manufactured part will be the lowest. Accordingly, if you choose the wrong cutting tool, it will most likely break, and this will bring damage. So how to determine the necessary tools and cutting conditions during turning? The table below will help you choose the best cutter.

Cutting layer thickness

As mentioned earlier, each of the stagesprocessing requires some accuracy. These indicators are very important when calculating the thickness of the layer being cut. Cutting modes during turning ensure the selection of the most optimal values for turning parts. If we neglect them and do not perform the calculation, then it is possible to break both the cutting tool and the part itself.

So, first you need to choose the thicknessshear layer. When the cutter passes through the metal, it cuts off a certain part of it. The thickness or depth of cut (t) is the distance that the tool will take in a single pass. It is important to bear in mind that for each subsequent processing it is necessary to perform a cutting mode calculation. For example, you should perform external turning parts D = 33.5 mm in diameter D1= 30.2 mm and internally boring hole d = 3.2 mm per d2 = 2 mm.

For each of the operations, the calculation of cutting conditions atturning will be individual. In order to calculate the cutting depth, it is necessary to subtract from the diameter after processing the diameter of the workpiece and divide by two. In our example we get:

t = (33.5 - 30.2) / 2 = 1.65 mm

If the diameters have too much difference,for example, 40 mm, then, as a rule, it must be divided by 2, and the resulting number will be the number of passes, and the depth will correspond to two millimeters. For rough turning, you can select a cutting depth from 1 to 3 mm, and for finishing turning, from 0.5 to 1 mm. If the end face is trimmed, the thickness of the material being removed will be the depth of cut.

Assignment of feed

Calculation of cutting conditions during turningIt is impossible to imagine without the amount of movement of the cutting tool in one revolution of the part - feed (S). Its choice depends on the required roughness and the degree of accuracy of the workpiece, if it is finishing. When the draft is permissible to use the maximum flow, based on the strength of the material and the rigidity of its installation. You can select the desired feed using the table below.

After S has been selected, it must be clarified in the passport of the machine.

Cutting speed

Very important values affecting the modescutting during turning, are the cutting speed (v) and spindle speed (n). In order to calculate the first value, use the formula:

V = (π x D x n) / 1000,

where π is Pi number equal to 3,12;

D is the maximum diameter of the part;

n is the spindle speed.

If the last value remains unchanged, thenthe rotation speed will be the greater, the larger the diameter of the workpiece. This formula is suitable if the spindle rotational speed is known, otherwise it is necessary to use the formula:

v = (Cat x Kat) / (Tm x t x S),

where t and S are the calculated cutting depth and feed, and CatToat, T - coefficients depending on the mechanical properties and structure of the material. Their values can be taken in the cutting data tables.

Cutting Mode Calculator

Who can help to perform the calculation of cutting conditions during turning? Online programs on many Internet resources cope with this task as well as a human being.

Существует возможность использовать утилиты как on a stationary computer and on the phone. They are very comfortable and do not require special skills. In the fields you must enter the required values: feed, depth of cut, material of the workpiece and the cutting tool, as well as all the necessary dimensions. This will allow you to get a comprehensive and fast calculation of all the necessary data.