CNC woodworking machine usedfor processing wood, plywood, chipboard, MDF in terms of milling and engraving. The CNC unit allows you to optimize complex manufacturing processes of furniture elements, friezes and other operations with high accuracy and speed.

Short description

CNC woodworking machine (numericalsoftware control) is a unit with an intelligent unit that reads the program and controls the drive equipment. Simply put, after the operator codes the program codes, the computer controls all the processes. By type of units are divided into:

- Combined options.

- Models for working with thread.

- The modifications processing not only wood, but also plastic, a stone, metal.

With the advent of the production of CNC equipmentthe process of wood processing, including the manufacture of any carved elements, is greatly simplified, the accuracy and speed of work increases, and the cost price is an order of magnitude lower compared to manual processing.

Features

CNC woodworking machines oftenused for through cutting of the workpiece. For example, it is very easy to mill MDF, even to the entire height of the part in one pass of the cutter. Other materials, depending on density and other characteristics, require several processing attempts.

Products made on such equipment havehigh accuracy and quality of processing (for example, in the production of floorboard). The disadvantages can be attributed to the moment that at high speeds, a place of cutting is characterized by a slight burning. In addition, on a CNC machine, it is difficult to obtain processing of sharp boundaries of engraving lines (rounding remains, equal to the cutter radius).

Scope of application

CNC woodworking machine usedto perform complex and time-consuming work. Used equipment in mass production of furniture, facades, doors and linings, flooring, decorative elements, parts of outdoor advertising.

In addition, a CNC woodworking milling machine is used to manufacture the following products:

- Baluster and other shaped parts for stairs.

- Items and facades of furniture.

- Carved frames for mirrors, paintings, wall clocks.

- Wooden icons.

- Baguettes, brackets, linings.

- Items with artistic carvings.

The complexity and cost of woodcarving is determined by the characteristics of the product itself. The smaller and more complex the details of the patterns, the higher the price of the finished product.

Possibilities of some modifications

CNC woodworking milling machineCNC-3520-1R-350 is equipped with a one-piece welded bed, which provides reliable stability even when processing massive and heavy products. On this equipment, you can perform three-dimensional thread on the radial areas of workpieces with a large diameter and a maximum length of up to 2 thousand millimeters.

Model 1318-3HR-300 is aa three-spindle machine for turning and milling of workpieces up to one and a half meters in length and 25 cm in diameter. The adjustable back headstock allows you to quickly switch from flat milling to turning and back.

Modifications of CNC machines can be equippedvacuum tables, several spindles, laser equipment and a combination of various tools, which allows you to process several parts at the same time, to perform various processes and high-precision engraving.

General characteristics

Technical characteristics which the machine hasCNC woodworking, depend on its equipment, size, additional functionality, manufacturer. Consider the main indicators of some modifications.

Machine "Art-Master 315 Racer":

- The unit is equipped with a vacuum table.

- It has an automatic waste disposal device.

- There is a turning shop for automatic change of cutters (4 pcs.).

- The compressed air supply pressure is at least 6 kgf / sq. cm.

- Operating voltage - 220 V.

- There is a pneumatic device for placing the workpiece, a scanner.

CNC-1500-1R assembly:

- Spindle characteristics - 2.2 kW, water cooling.

- Guide elements - round, located along the Z axis.

- Power supply - 220 V.

- Ball screw transmission on all axes.

- The maximum indicator for the dimensions of the workpiece (length / diameter) is 150/20 cm.

Household options

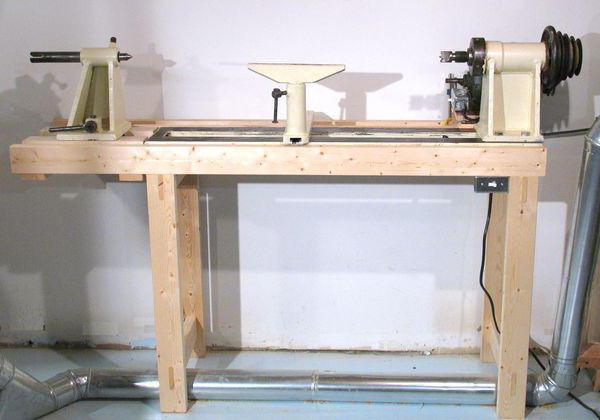

For home use or keeping smallbusiness, woodworking CNC machines for wood carving can be built with your own hands. This will require the purchase of standard electronic and software components. Depending on the need, the equipment is assembled according to the desired type (in terms of the mechanical part). Improvements easy to make, having studied the drawings and installation diagrams of the unit, which can be found on the Internet.

As evidenced by user reviews, machine toolsCNC greatly facilitates and accelerates the process of processing wooden blanks. At the same time, high accuracy and quality of finish is maintained. It should be noted that the equipment assembled at home will cost much less than the factory version. Of course, for serial production, medium-sized businesses and industrial volumes, we need modernized machines that have the most automated control and the ability to perform several processes at the same time.

Conclusion

Considering all the features that have CNC woodworking machines for carving, we can note the following:

- For volumetric production, there are rotary tables provided, allowing to program the adjustment of the workpiece in the corners and in the plane.

- Almost all manual carving techniques can be imitated on CNC devices.

- Unfortunately, it is almost impossible to imitate the technique of geometric thread due to the technological features of the milling and cutting processes.

In any case, software-controlled machining is high performance combined with excellent quality at a low cost.