Glass is one of the most ancient materialswhich is widely used in all spheres of practical human activity due to a set of useful qualities and properties. During its existence (and this is more than 5 thousand years), its chemical formula has remained almost the same, only its qualities have changed.

Quartz glass

For years, man sought to createglass is increasingly transparent and resistant to various destructive factors. As a result of this purposeful improvement, quartz glasses appeared - a completely new type of material with mind-affecting characteristics. Perhaps it is this glass that will determine the direction of the future development of humanity.

Quartz glass structure

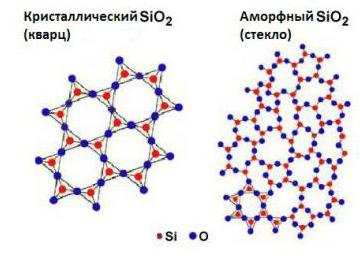

The material is amorphous due to its structure, which is based on silicon-oxygen tetrahedra. SiO Molecules2 "Communicate" with each other due to the mutual attraction of oxygen atoms.

Silicate glass, as usual, is produced bymelting feedstock. Pure silica can be used as such - rock crystal, vein quartz, quartz sand, and also silicon oxide obtained by artificial means.

The differences of quartz glass from the usual

Depending on the type of raw material chosen, certain properties of the final product are also determined. So, to get a crystal clear and transparent material using rock crystal.

The main difference of silicate glass from the usual is a high melting point - more than 1500 Сabout. In this case, silicon oxide begins to emit intense light radiation in the visible spectrum, that is, it starts to glow.

Due to the amorphous structure of the raw materials, the melting processcan last a considerable time. The molten composition has a high viscosity, which does not allow it to be melted or moved. This makes it difficult to produce quartz glass with the same wall thickness.

Production features

In view of all the listed featuresproduction of silicate glass is possible only on specialized equipment. High temperature must be maintained in the smelters, and to create glass products it is necessary to maintain a jet of an open flame at a temperature of 1800 ° Cabout and higher.

There are special requirements forproduction room - it must be sterile. A small number of foreign particles will inevitably lead to the fact that the finished quartz glass will soon crack and lose their properties.

All basic glass blower tools are made.from heat-resistant materials - granite, tungsten, which, among other things, are very heavy. Therefore, employees must be physically strong and resilient.

Quartz glass properties

Silicate glass has low rateselectrical conductivity, so it is often used as a dielectric in complex electrical appliances. The main beneficial properties that quartz glasses possess can be divided into three groups:

- Thermal. Resistance to high temperatures (1200 Сabout), high thermal expansion coefficient(15 times higher than that of ordinary glass) than the resistance to sharp and significant temperature fluctuations (in production, products are cooled with a stream of ice water).

- Chemical. Glass is chemically neutral, does not react with all alkalis and acids, except phosphoric and hydrofluoric acid (the reaction begins at temperatures above 300 ° Cabout).

- Optical. The refractive index of quartz glass is 150 times lower than that of normal (ne= 1.46). Because of this, it perfectly transmits not only solar and ordinary light, but does not block either infrared or ultraviolet radiation.

All these properties allow the use of quartzglass as a building material, as well as for the production of laboratory glassware, optical instruments, electrical equipment, heat-resistant refractory materials. One of the main areas of its application is the manufacture of optical fibers.

Optical quartz glass

Depending on the used in the productionQuartz glass technology may be opaque and transparent. In the first case, a large number of gas bubbles will be present in its structure, which intensively scatter light.

Optical glass brands and series

There are several brands of optical glass:KU-1, KI, and KV. Products differ in the ability to transmit visible, ultraviolet and infrared radiation. The most transparent is KI glass - it is capable of transmitting light at a wavelength of 2600-2800 nm, the least transparent is KV.

- 0 - material used under normal operating conditions;

- 100 - glass resistant to ionizing radiation of insignificant force;

- 200 - raw materials that can be used in conditions of intensive ionizing radiation.

Brand and a series of glass form the cipher products.It is applied on the production and determines the specific type of glass. In our country there is no single encryption system, so each company designates its products according to its own understanding.

Application area

Large silicate glass is produced.quantity of various products. In scientific and industrial laboratories, quartz glass tubes are in demand, which are used to measure the level of a liquid, manufacture electric heaters, conduct chemical reactions, and store corrosive substances.

Widespread use in production and receivedopaque glass. It is used where control of liquid products is necessary at high temperatures and, due to low cost, is applied everywhere.

Optical glass is used in sudo androcket production, mainly for the production of lighting devices. In petrochemical plants, this material is valued for its high chemical resistance and is used to control corrosive liquids. In airplanes they glaze cabins, and also use them as thermal insulation.

Manufacturers make products according to the requirements of GOST 22291-83. Quartz glass, tubes, windows, prisms, lenses and other products are made both in large quantities and individually.