What miracles are not cooked on Earth forman! For example, an amazing sight is white sand. From a distance you will not understand at once: whether it is drifts in the middle of summer, or mountains of granulated sugar, or perhaps table salt or another chemical? And only getting closer, taking it on the palm and waking through your fingers, you realize that this is white sand, the photo of which is given in this article. And it consists of quartz - a mineral distributed on Earth. Quartz is part of the mineral composition of oligomictic and polymictic sands, which form desert barkhans, dunes of sea coasts, shallow waters.

Natural white sand

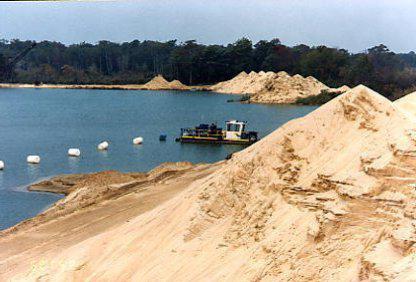

Quartz sand deposits occur invalleys of rivers. The white river sand is the cleanest, it usually does not contain pollutants, as well as mountain quartz sand, weathered vein outcrops. It is quite possible to meet nuggets of precious metals or their minerals in deposits of natural quartz sand. It happens that white sand is buried beneath the thicknesses of other sedimentary rocks and is mined by the quarry method. It usually contains contaminants in the form of impurities of clays, sandy loams, loams, polymictic sands, which occur in the thickness of quartz sand in the form of interlayers and lenses.

Creation of nature and hands of human beings

White sand, consisting of 90-95% of quartz,meets not so often and is very much appreciated as raw material for many industries. The lack of natural sand can be replenished - to obtain artificial quartz sand, using crushing and sorting equipment. For the production of sand, monolithic blocks of milky white quartz are used, crushing which, and sifting the destroyed rock, produces sand with certain and desired particle sizes (fractions). From natural sand artificial is distinguished by exceptional monominerality, acute angularity of grains of sand.

Where to use quartz sand

White sand is used for glass production.It is subject to such requirements: 95% of it is quartz, it should be medium-grained (0.25-0.5 mm diameter of grains), without admixture of substances that are hardly soluble in the glass mass, without harmful impurities of minerals containing iron, chromium, titanium (they color the glass and increase its light absorption). A good glass sand is one that is 98.5% quartz and includes iron oxide not more than 0.1%.