Распределитель гидравлический изготавливают из various grades of steel, modified cast iron and bronze by casting. Protection of structural elements is carried out by means of nitriding and cementing, which allows to provide the required technical conditions.

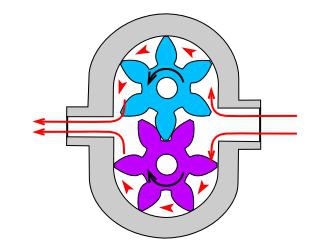

Classification of these devices is carried out inmainly in the form of regulating parts. In this regard, distinguish crane, valve, jet and spool systems. Let us consider some of them in more detail.

Valve distributor differssimplicity of manufacture, reliable operation and a long period of use. The undoubted advantage of these systems is also their high level of tightness. Structurally, the flow of the working fluid is modified by alternately opening and closing certain valves. The hydraulic distributor can be equipped with a manual, electrical and mechanical drive, necessary for the movement of the gates.

In addition to the basic classification, of course,there is an additional one, which allows us to distinguish between the hydraulic distributors by the ways of connection to the main system. There are three different designs: threaded, butt and flanged. Each of them is used in special cases and directly depends on the purpose of the distributor. In addition, the volume of the liquid passing through it also plays an important role. For example, spool valves are used in cases where it is necessary to redirect a large flow of working fluid, and crane, in turn, installed on systems with low consumption or used as an auxiliary equipment.