A modern developer is provided with a largechoice of building materials and building methods. In each case, there are a number of unique advantages, but I'd like to single out the frame construction technology. Its use is advisable in cases where the building needs to be built in record time, while the budget of the future homeowner is limited.

Step-by-step construction of frame houses caneven an inexperienced master, which eliminates the need to attract expensive specialists. On what basis this method of construction is based and what works it implies, we will consider in detail in our article.

Features and essence of modern technology

Technology of frame house construction(stage-by-stage) differs from the traditional building of buildings in that in this case the house is not erected, but is assembled. Initially, the foundation is installed skeleton of the future structure. It is made of metal or wooden profiles, which are fixed to each other by special fasteners. In some cases, the frame can be completely welded.

The finished base of the house is lined with woodenshields, between which is a heater. When the walls of the building are completely assembled, the builders mount the roof and proceed to the interior and exterior finishing. The main advantage of such buildings is the possibility to proceed to the decorative finishing of the premises immediately after the completion of its assembly. Unlike houses from a log house, these buildings are free of shrinkage, which allows you to install windows and doors without delay.

Step by step construction of a frame house with their own hands can be performed by a team of 2-3 people in just a couple of months, which attracts most of the fans of this method of housing construction.

The main stages of building assembly

The process of assembling buildings can be divided intoseveral parts. This allows you to control the costs at each stage of assembly and budget the budget for the following work. The phased construction of frame houses includes such events as:

- choosing a place for construction;

- the laying of utilities;

- creating a foundation for the house;

- tying the foundation;

- flooring of rough floor;

- assembly and installation of the frame;

- insulation of the structure;

- creating a roof;

- flooring of roofing material;

- processing.

All of the above steps do not require the presence ofexpensive and complex equipment. The work is quite simple and does not cause any special difficulties. To build a frame house with your own hands, a detailed step-by-step instruction should be available to all employees. This will help to avoid many mistakes. Do not forget about the plan for future construction. Its creation is better entrusted to experienced specialists.

Selection of materials for construction

One of the important preparatory stages is thechoice of materials from which the house will be assembled. If everything is extremely simple with the walls - for their installation use sheets of plywood or OSB slabs, then at the stage of assembling the frame there may be questions.

As stated earlier, the base for the walls can be assembled from wood or metal, we will consider what their differences are:

- Wooden frame. Private builders preferNatural material, as it is characterized by environmental friendliness, low cost and fast installation. But here it is important to understand that this design will be heavier than metal, which means that the base for it should be more durable.

- Metal frame. As for the metal profile, itsthe cost will be a third more expensive than the wooden one, but in the end the owner will get a safe, solid and fairly light foundation of the house, which does not require reinforcement of the foundation. Preferably this option and the fact that the place of attachment of screws does not need to be treated with anti-corrosion compounds.

Technology of construction of frame houses(step by step, with their own hands) implies an independent installation of a heater for walls. As for his choice, he must meet the requirements of fire safety and do not interfere with natural air exchange. Otherwise, the internal microclimate of the room may suffer significantly.

We build a frame house with our own hands: where to start?

At the first stage of construction of a frame house wewe will not dwell. With the choice of a place to build a house everything is clear - you need a flat and fairly spacious area. It must be cleaned of debris, remove all plantations. If there are any irregularities on the surface of the earth, they are eliminated. The mounds are cut off, and the cavities and pits are filled with earth.

Based on the project documentation is carried outsite marking. With the help of a cord and pegs designate the perimeter of the house and the internal (bearing) walls. The laying of utilities is not difficult, since it is carried out strictly in accordance with the plan of the house. It can be done both before and after installing the base of the house.

Foundation of a house

Let us now turn to the process of erecting a foundation. The technology of building a frame house and a step-by-step description of the whole process suggests that the basis for these structures can be of three types:

- tape;

- columnar;

- pile-screw.

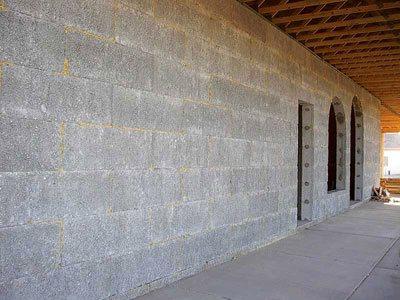

Ribbon foundation. Outwardly it looks like a concrete strip, insidewhich is the armature. To create it, a formwork is installed, into which a concrete solution is poured. The height of the basement may be different, but if a basement is planned in the house, the walls of the basement should be increased by 60-80 cm. In this case, they require insulation and the presence of ventilation holes.

The column foundation. This option is more preferable for wireframebuildings. Poles are installed under every corner of the house, at the intersection of walls and every 2 meters under the external and load-bearing elements of the house. Under the pillars dig a hole at the bottom of which have a sand cushion. At the bottom of the recess they arrange the formwork, lay the waterproofing material. After the preparatory work is poured concrete.

Pile-screw foundation. Ready piles are screwed into the ground strictly in level and are poured with concrete. Such a foundation is used in soil with a high level of groundwater and on uneven areas.

Base casing

Those masters who decided to build a frame house with their own hands, the advice of experts will help to avoid mistakes. Experienced builders recommend performing the strapping as follows:

- Pre-prepared wooden bars (section 20x20 or 20x25) treated with antiseptic composition.

- The metal or concrete base should be smeared with mastic and covered with waterproofing material.

- On the perimeter of the foundation lay the bar so that itcovered its entire surface. If the length of the beam is not enough, then it is possible to join 2 elements. The joints must be located strictly above the posts. Fastening is performed by screws.

To the foundation, the strapping is secured with large bolts and studs. Fasteners need to be deepened into the material.

Creating a floor

A roughing floor is mounted on top of the strapping.First, logs are installed. To do this, take wooden beams cross-section 10x12 centimeters and lay on the obvjazku foundation with a step of 0.6-0.7 meters. The lag is secured with nails and corners.

The next step in the phased constructionframe houses is laying the rough floor. For its arrangement the cheapest material is used - unedged board. The resulting surface is covered with waterproofing, insulation and vapor barrier material. Top plywood sheets, OSB or floorboard.

Frame house: step by step instruction on assembling the base of walls

Build the walls of the house begins with the creation of a frame. It is done as follows:

- According to the scheme for assembling the structure on the floorcollect one span of the wall, which is subsequently installed on the harness and fixed at the base by nails and corners. The frames of the frame are fixed at the upper and lower horizontal wall elements. At the corners of the beam is fastened by cutting, all the other posts are fixed with corners of steel.

- Distance between vertical beams (racksskeleton) is determined depending on the width of the sheet of the chosen insulation. If you plan to use mineral wool, then this gap is reduced by 2 cm, so that the soft material denser lay down in the empty space of the wall.

- To give the structure additional rigidityBetween the vertical columns of the walls (in staggered order) horizontal jumpers are fixed. Window and door openings are arranged in the same way. On the edges of the hole - the posts, and from above and from below - by crosspieces.

- Internal partitions are assembled and fastenedsimilar method. The finished construction of the house is tied with a board from above, which gives it extra rigidity. Next, the walls are sheathed with sheet shaving materials.

Creating a roof ceiling

Step by step construction of the frame house byhands almost done. It remains to collect the roof, and you can proceed to finish the finish. To fix the ceiling beams in the bar of the top harness, it is necessary to make grooves. For reliability, the beams are fixed with metal fasteners. Above the beams, the ceiling is pounded from the tongue-and-groove boards.

Staged construction of frame houses in onethe level is slightly different from the erection of multi-storey buildings. In the first variant, a vapor barrier, heat-insulating and waterproofing material is laid over the sheeted board, which is covered with an unedged board or plywood. If the house has several floors, then further lay the flooring from the sheet pile.

Roof installation

The construction of the roof is the most important thing, especiallyfor those builders who decided to build a frame house with their own hands. The recommendations of experienced developers should be studied before the work starts. They say that the work should be performed in this order:

- Determine the required roof slope and itsvariety. For simple single-storey buildings it is better to use gable structures. On houses with a flat roof, only single-deck varieties are installed. The roof on the buildings with the veranda can be of a combined type: above the veranda - a one-run, and above the house - a gable roof.

- Based on the parameters of the insulation, choose the desired section of rafters. The material should be free to fit and stay in between.

- Further, two boards (6 meters long) connectwith the letter "L" and lifted to the roof, where they are placed on the upper strap so that the edges of the rafters hang down for 30-50 cm. The design is fixed with a bolt and used as a model for rafters. Next, the rafters are installed at a distance of 0.7 meters from each other.

- In the ridge the rafters are fixed by the method "in the floorpaws. "First of all, they are mounted on pediments, wire is drawn between the rafters, which indicates the level for installing the rest of the roof elements.

When the main frame is ready, on the raftersthe lath is stuffed. Depending on the chosen roofing material, it can be either solid or thinned. Separately, it should be noted that any kind of crate in the area of the ridge is fixed without gaps.

Thermal insulation of the house

Now go to the final part of the assemblyframe house in stages. The construction and technology of the erection of such buildings implies the performance of works for their insulation. For this purpose, foam expanded polystyrene, mineral wool and polystyrene are most often used.

The thickness of the insulation layer is chosen taking into account the climate and the purpose of the room. For the year-round residence in the house, the thickness of the thermal insulation must be at least 5 cm.

The insulation is placed densely between the verticalbeams of the frame so that each successive layer covers the docking points of the previous one. The walls are fixed with a vapor barrier material, after which they are sewn up with OSB (plates). Outside, the facade is covered with waterproofing and the crate is installed from thin rails, which will serve as the basis for the external cladding and will ensure the ventilation of the building.

Finish

When the construction work is completed, you canbegin to finish the building. The style and method of interior walling depends solely on the capabilities and wishes of the building owner. The only thing that the owners of the house must take into account is that the material should not heavily burden the walls.

External cladding can also be performed indifferent variants. Most often for these purposes use siding, block house, lining or other decorative materials. For example, the phased construction of a frame house in the Art Nouveau style implies the use of light and simple materials. In this case, it is advisable to use plaster. For lovers of Provence ideal for light imitation of brick and natural stone.

Conclusion

The main advantages of frame structuresare assembly speed and economy. Thanks to this technology, a much larger number of people can afford their own house, which will fully meet all the wishes and requirements of the family.

The principle of erecting such structures is soIt is simple, that does not cause difficulties even for beginning builders. The main requirement is strict adherence to the technology and stages of the frame house construction, which means that if you do not make mistakes, this house will rejoice the owners for many years with warmth and comfort.