The carriage for the circular do it yourself prettyoften made by novice craftsmen and specialists. This element is an indispensable device in the workshop. With it, you can quickly and safely carry out the exact cutting of the workpiece, eliminating the likelihood of reverse impact.

Recommendations for work

If you will run a carriage forcirculars with your own hands, it is necessary to choose the size of the base of the sled, their parameters should be equal to the size of the circular table. For the stops, one of which is located behind, the other - in front, you must use wood with straight fibers, like cherry or maple.

The material should be moderately dense.It is important to make sure that the stops have perpendicular edges, and their length must correspond to the width of the base. When the carriage for the circular is performed with your own hands, it is important to ensure that the rear and front stops have an increase in the place where the saw blade passes.

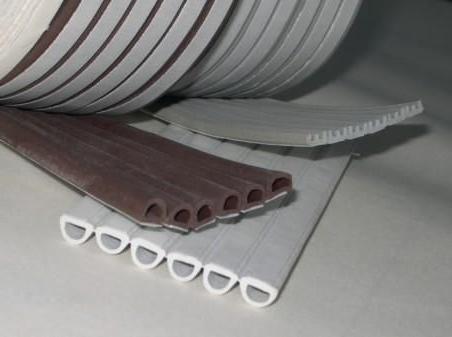

The band saw will round the sides of the stops forconvenience and weight reduction. To perform the guide bar, you must use hardwood, as it is quite dense. The size of the bar should be equal to the parameters of the groove in the circular table. Given the dimensions of the saw blade, it will be necessary to perform a protective casing, and then to round off the near corner.

Build Wizard Recommendations

When the carriage for the circular is executedhands, it is important to remember that the protective cover should not act as a handle, it should not be operated when moving the sled. To assemble the rear stop is attached to the base, and in the lower part it is necessary to drill holes for the installation of screws.

In the groove of the circular table must be installedguide strip, which is pre-treated with a layer of glue. The base should be placed perpendicular to the saw blade on the guide bar; the element should be left in this state until it is completely dry. At the next stage, you need to take a few screws to strengthen the guide bar.

Conclusion

You can make a circular carriagewith your own hands, the photo of which you can see in the article. After completion of all the above works, it is necessary to turn the base so that the grooves on the circular table coincide. If there is a need, then you can additionally use sandpaper or scraper, with the help of which excess wood is removed.