Comfortable existence of tenants of moderna country house provides a powerful network of various engineering communications, among which one of the main places is occupied by the system responsible for heat. Planning to mount it on its own, almost every owner wonders about which pipe diameter for heating a private house to choose. For many, this becomes a real problem, since it is the size of the pipes that determines the final cost and the efficiency of the heating system.

Factors affecting the choice of pipes

Choosing the diameter of pipes for heating a private houseplays a really important role, since this parameter will determine the throughput of the heat system, as well as its thermal and hydraulic losses. In addition, it is necessary to take into account the scale of the installed system, namely the number of radiators and rooms that require heating. Many people think that the larger the diameter of the pipe for heating a private house, the greater its throughput, which means that the number of radiators can be increased.

However, to increase the efficiency in this way is unlikelywhether it will be possible. Not only that the purchase of pipes with an unnecessarily large cross section will entail additional costs, so also there is a risk of pressure drop in the system to a critical value and, as a consequence, a decrease in efficiency.

Thermotechnical calculation

Calculation of the diameter of heat supply pipes is performed withtaking into account the material from which they are made, the length of the contour, the wiring diagram and the principle of circulation of the coolant. It is quite difficult to perform the calculation correctly, especially if there is no experience in such cases. It is best to contact a specialist who will be able to develop a competent project for heating a private home.

When compiling it, the following parameters of the future heating system must be taken into account:

- a wiring diagram based on which the total length of the pipes is calculated;

- coefficient of resistance of the pipe for the heating system to the flow of liquid (this figure is affected by the size, material and smoothness of the inner surface of the product);

- sections of the output and inlet connections of the boiler (they are usually identical);

- internal diameter of the pipe for heating the private house (the internal section is indicated in millimeters or inches, 1 inch = 25.4 mm);

- coolant level;

- the maximum rate of flow of the coolant;

- the amount of heat that must be transferred from the boiler to all radiators.

Principle of calculations

Making up the project of heating a private house, a specialist focuses on the optimal indicators that must be achieved when creating a new system. For example:

- The speed of water movement in the system should not exceed 1.5 m / sec. The optimum option is from 0.3 to 0.7 m / s.

- The degree of cooling of the water coolant (the temperature difference in the water entering and leaving the boiler) must be in the range of 15-20 degrees.

- The amount of heat required by the system must beequal to the total power of all radiators (the maximum indicator is taken from the passport). For heating 10 square meters. meters of the area of the insulated room requires 1 kW plus a margin of 15-20%.

Systems with natural circulation

The maximum pipe diameter for private heatingThe house equipped with a heating system with natural or combined circulation should correspond to the sizes of the boiler inlet and outlet (most often they are the same). Pipes of this type will be needed to perform the initial and final sections of the contour.

If we talk about what kind of pipe for heatingprivate house is better, then you need to consider the type of boiler. So for solid fuel boilers it is recommended to use metal products. If you plan to use polymer pipes, then for installation of the first couple of meters, you should still use a metal pipe.

The starting diameter is the largest.It is maintained until the first branch. Further, the wiring is performed with a gradual reduction in the diameter of the pipes after each branch. At the last point, the diameter should be ½ inch (12.7 mm) or ¾ inch (19 mm). When installing the "return" the same principle applies.

Systems with forced circulation

Such systems usually operate on gas orelectric boilers. The diameter of the pipes for them should be chosen the smallest, as the forced circulation provides the pump. The feasibility of small diameter pipes is explained by the following factors:

- The smaller cross-section (most often these are polymer pipes or metal-plastic pipes) allows to minimize the volume of water in the system and, consequently, to accelerate its heating (the inertness of the system decreases);

- the installation of thin pipes is much easier, especially if they need to be hidden in the walls (making the slab in the floor or walls requires less labor);

- pipes of small diameters and connecting fittings to them are cheaper, therefore, the total cost of installing the heating system is reduced.

With all this, the pipe size should be optimalcomply with the indicators stipulated by technological calculations. If these recommendations are not followed, the efficiency of the heating system will decrease, and its noise will increase.

Connecting radiators

With a collector wiring diagram, boiler andthe collectors are connected by pipes of larger section (from 19 to 25 mm). Wiring from the collectors is carried out using thin tubes, the inner diameter of which is 12.7 mm (1/2 inch).

Radiators, as well as additional equipment, in particular, a safety unit, pumping storage tank, etc., are also connected with half-inch pipes.

Types of radiators

Относительно того, какое отопления лучше для private house, the owners of the reviews are quite diverse, but with regard to radiators, many prefer aluminum models. The fact is that the power of radiators depends on the material. They are bimetallic, cast iron and aluminum.

One section of a bimetallic radiator has a standard power of 100-180 W, cast iron - 120-160 W, and aluminum - 180-205 W.

When buying radiators, it is necessary to find out exactly what material they are made of, since this indicator is required for the correct calculation of power.

Types of pipes for heating

The heated water is transported from the boiler to the radiators through pipes, so their quality directly affects the level of heat loss. Three types of pipes are currently represented on the building materials market:

- metal;

- copper;

- metal plastic.

Each species has its own characteristics, which will be discussed below.

Metal pipes

This option was previously commonly used inheating systems of high-rise and private houses. Metal pipes are gradually becoming a thing of the past, as they are not characterized from their best. Their disadvantages include:

- big weight;

- problematic installation (requires professional equipment);

- the ability to accumulate static electricity;

- limited service life due to inability to resist rust.

Copper pipes

Such products have several advantages, for example:

- the ability to withstand high temperatures (within 200 degrees);

- high strength (maximum pressure - 200 atmospheres);

- durability (non-corrosive).

However, copper pipes are not popular, and the reasons are as follows:

- the complexity of installation (requires silver solder, professional equipment and special skills);

- installation of copper pipes requires special brackets;

- high price (copper - expensive material);

- high cost of work due to their labor intensity.

Metal pipes

This type of pipe is the most sought afterconsumers. Such products are produced in a wide standard range and are ideal for installation of heating systems. They have the following advantages:

- increased strength and durability (aluminumor a fiberglass base coated with plastic generally creates a high-strength structure that does not collapse with time and is resistant to mechanical damage);

- resistance to corrosion processes (hermetic outer coating does not allow air);

- minimum hydraulic resistance (such pipes are ideal for heating systems with natural and forced water circulation);

- possess antistatic property;

- simplicity and high speed of installation (installation does not require professional knowledge, it is enough to get acquainted with the installation technique on the Internet and purchase a special soldering iron);

- low cost of pipes of any diameters and accessories to them.

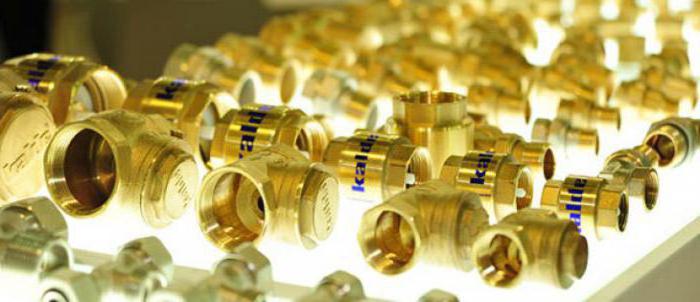

Reliable connection of elements providespecial elements - fittings. If metal-plastic pipes must be connected to metal or stop valves, flanges or adapters to the threaded connection are used.

When installing the heating system from pipes and fittings reinforced with fiberglass, the operation of stripping these elements is not required, which significantly speeds up and simplifies the work.

Thus, metal pipes arethe best option for self-installation of the heating system. The main thing is to choose the right amount and diameter of pipes and components (fittings).