When building buildings, wooden elementsdesigns are often connected with nails. However, this procedure requires a lot of strength, as well as the presence of certain skills. To work performed much easier and faster, you should use a more modern method, in which when connecting a special fastener for wooden structures made of metal is used. With the help of these parts, even a person who does not have any special experience in construction can build a building without the help of professionals.

What it is

Fasteners for wooden structures is an element withspecific purpose, having a different configuration, size. These parts are made of high-quality galvanized steel sheet with holes for bolts or nails. It is this material that is used in the manufacture of fasteners, since it has high strength and resistance to moisture. Products made from it are not subject to corrosion, have a sufficiently long service life.

Metal elements that are attachedwooden structures must be manufactured in the factory. Only they can ensure the quality and durability of the connections. Today, manufacturers offer a wide selection of different fasteners. The main thing is to choose the right type for a specific type of work.

Types of fasteners and their use

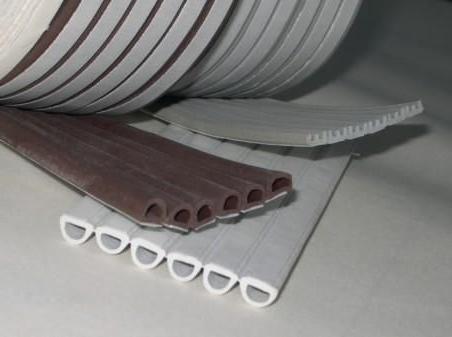

There are two types of parts:lamellar and shaped. Fasteners for wooden structures of each type are made in different sizes. This allows it to be used in buildings with different parameters.

Perforated fasteners for wooden structurescontains holes for bolts or nails. It is able to make a reliable and durable connection of several elements that are at the required angle in the same plane. The mounting plates are attached to the node on both sides. Used in the cosmetic and overhaul, fastening elements of the facade, the construction of the roof of the building.

Gear metal plates are madeby cutting galvanized steel sheets. They are used in the same place as perforated fixtures, but their installation is carried out mainly in industrial conditions. Fastening with the help of such plates is carried out by the indentation method. This technology allows you to create absolutely identical designs of any complexity. To ensure a reliable and durable connection, nail fasteners are prohibited. Therefore, this type of use directly on the construction site is inefficient.

Rafter beams are designed for perpendicular elements of the roof, which are supported by each other. They are also used in the installation of transverse parts.

Beam supports are used in fastening horizontal bearing elements with nails or bolts to different parts of the structure at right angles. Produce them in various sizes.

The sliding connection of rafters is intended for the construction of houses from a log or a bar at the device of inclined details.

Metal fasteners for wooden structuresvery beneficial and effective to use, because it has a lot of advantages. The main thing is that it contributes to the reduction of carpentry work, as well as the acceleration of the entire construction process.

Required connection conditions

Fasteners for wooden structures in the form of shaped or flat elements for installation in node connections require the fulfillment of certain conditions:

- all parts made of wood must be at least 5 cm thick;

- When mounting, only brushed or screw nails should be used;

- use screws with a diameter of at least 4 mm, a length of 40 mm;

- do not leave between the mounted parts of the gaps, they should fit snugly.

BaLolo alemeNTV

Do you need a beam fixture for wooden structures? The catalog of these products in hardware stores usually consists of the following models:

- Bracket WB - made of galvanized steel. This product is mounted console bearing beams for the construction of houses with wooden floors. It is fixed with screws or anchor bolts.

- Separate mounting of the WBD provides mounting of the console of bearing elements with non-standard parameters.

Crepeto builddrank

In the construction market are in demand types of fasteners for rafters with the following marking:

- LK - used in the construction of roofs and ceilings in the roof system of the house, fastened with screws or special nails.

- Reinforced corner KP - is used when mounting the bearing parts in wooden houses, fixed with pierced nails.

Compounds with enhanced properties

Some parts of the buildings, on which the greatest load falls during the operation, require installation with the help of reinforced elements. For example:

- TM perforated tape is used in the joints of the assembly and auxiliary parts, and it is fixed with self-tapping screws;

- The corners of models KP5, KP6, KP11, KP21 are designed for mounting wooden parts with a large load, have oval holes that provide a solid and reliable anchoring.

Standbridge connectioneni

If you need to buy hardware forwooden construction, its price will depend on the type of product, size, shape and features. So that you could approximately imagine how much a set of parts will cost, we give the approximate cost of their most frequently used types:

- nail plate - 60 p .;

- wide corner KS - 6 p .;

- mounting 135KLD - 46 p .;

- perforated KL - 14p .;

- narrow KW - 2 p .;

- reinforced KPW - 3 p .;

- beam KB - 22 p .;

- fastening beams WB - 100 p .;

- flat mount - 6 p .;

- symmetric square KP - 5 p .;

- for LK rafters - 26 p.

Using specially madefactory conditions of fasteners in the construction of the wooden parts of the building reduces the cost of purchasing raw materials, as well as significantly simplify and speed up the installation process. After weighing all the pros and cons, we can conclude that the use of metal fasteners during construction is quite profitable, the financial costs of them are fully justified.