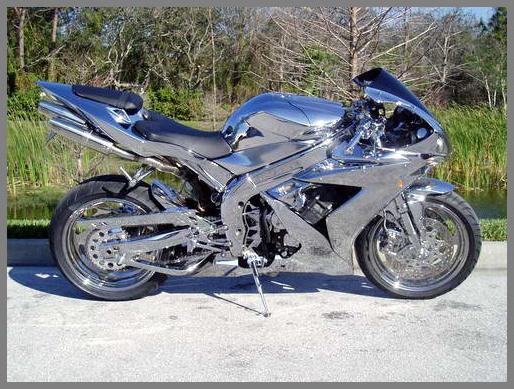

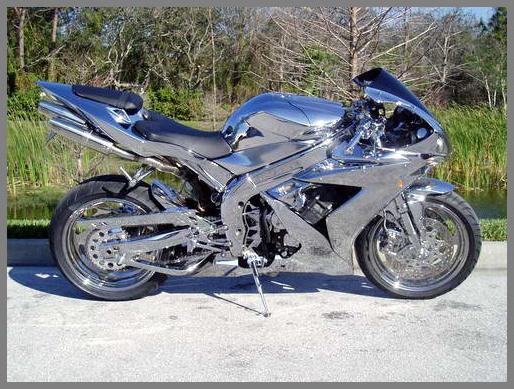

Chrome plating is one of thefavorite activities for many people. It is important to understand that this process is life-threatening. At industrial plants, chromium is produced using special equipment. In this case, chemical or chemical-thermal treatments are used. However, you can do this at home, if you stock up with the necessary equipment and knowledge.

To make chrome-plating with your own hands,it is necessary to prepare an enameled container. You will also need a blowtorch, certain chemical mixtures, as well as knowledge of the chemical process. First, it is necessary to determine what kinds of elements of the periodic table can be used for a certain type of metal. It is also important to know in what order the processing will be carried out.

Chromirovanie own hands should start withpreparation of the parts to be processed. They need to be polished and degreased. This is done to remove all the organic contaminants that are on the parts at this time. At home, this is done by treating the elements in an alkali solution or by washing them with a good detergent. Further on the details it is required to isolate all the parts that should not be chrome plated. As a material for insulation, lead is quite appropriate. It is resistant to electrolyte, so it is not chrome plated.

The next step is to install the parts.They must be mounted on suspensions, as well as other devices that are good conductors. This is necessary to supply current to the parts, as well as to spread it throughout the area. The contacts must be as reliable as possible, since the currents passing through them are sufficiently powerful. In this process, they bear the main burden. It is important to understand that in no case should the chrome parts be screened.

Chrome discs with their own hands can startafter all the preparatory work has been carried out. This is done so. The prepared parts are lowered into a bath filled with chromium oxide, water, and free radicals, which ensure a high quality of the result. After this, you need to pull out the product, but do it with gloves, otherwise you can get severe burns. After the part has cooled slightly, it should be thoroughly polished, which will remove any precipitation from the surface. Chrome plating of plastic is made in the same way.

It is important to remember the precautionary measures, especiallythis applies to the room that you have chosen for the procedure. The whole process is accompanied by abundant release of hydrogen and oxygen. Droplets of electrolyte condense into the fog, irritating the mucous membranes of a person, which can lead to negative consequences. This is why chrome plating is required to be carried out in an open room.