In the process of designing systems that provideproduction objectives, takes into account many operational nuances. Each complex is individual, but the principles of its implementation are based on a basic set of requirements. The system must be efficient, reliable, functional and at the same time ergonomic. A link between the directly technical part of the production supply and control tasks is implemented by controllers for automating processes. They concentrate information coming from different technological areas, which serves as the basis for making certain decisions.

Controller classification by scope

Virtually every modern enterprise into a certain extent, uses systems that automate workflows. Moreover, the nature of the serviced functions may be completely different. Thus, in the chemical industry, the programmable equipment controls the dosing, the flow volumes of bulk and liquid materials through the controllers, monitors the properties of various substances with the help of sensors, etc. In the service sector of transport organizations, the emphasis is on the management of power equipment, as a rule, loading and unloading. Universal controllers for automation of ventilation, heating and water supply systems are also widespread. This is a group of systems that manage engineering and utility services at enterprises in various fields. And on the contrary, there are highly specialized areas in which individual development of systems for specific needs is needed. These areas include the oil industry and steel mills.

The principle of the controllers

Industrial controller ismicroprocessor, which provides for hardware and software. The first part, in fact, serves the physical work of the system, based on the nested program for performing tasks. An important aspect of any configuration of this type is the regulatory infrastructure. That is, the program basis is responsible for making certain decisions, but in the future, the received signals are sent to command points sent directly to the working equipment. Thus, automation controllers control machine tools, conveyor lines, technical power equipment, etc.

Another equally important component of the overallcontrol infrastructure are sensors and indicators, on the basis of indicators of which the controller generates solutions or strategic chains that determine the operating modes of the equipment. It can be sensors that assess the state of the machines and units, the materials being serviced, the microclimate parameters in the production area and other characteristics.

Automation Controller Architecture

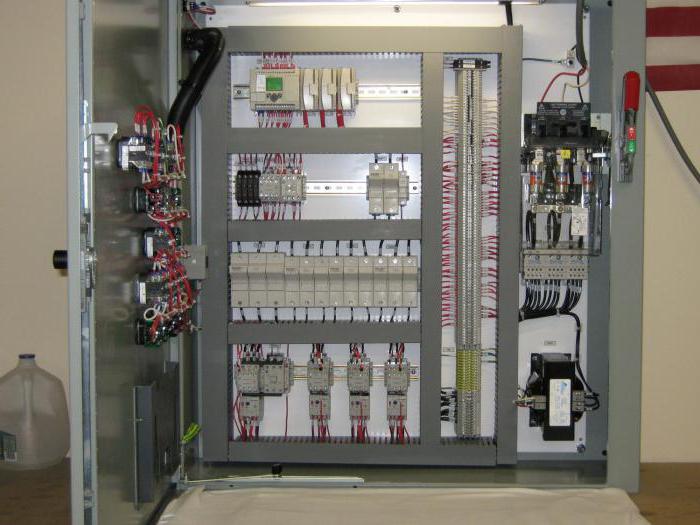

The controller architecture is understood asa set of components, due to which the control function of automation is realized. As a rule, the architectural configuration assumes the presence in the complex of a processor, network interfaces, storage device and input-output systems. This is the basic equipment, but depending on the needs of a particular project, the composition and characteristics of individual parts may vary. Complex automation controllers are called modular. If the traditional simple architecture is a unified unit with a typical set of functional elements that are not accessible to change by the operator, then in complex architectural models a multi-component modular configuration is implemented. It allows not just maintenance of a single closed unit, but also each module separately. Now it is worth considering the individual parts of the architecture in more detail.

Variety of architecture modules

Basic modular device is presentedmicroprocessor. Its power depends on how complex the tasks solved by a specific controller can be. Also the memory device matters. It can be integrated into the system without the possibility of further change. But most often used external flash memory modules, which can be changed depending on current tasks. Responsibility for actions taken by industrial automation controllers is largely borne by I / O devices. On these channels, the processor receives information for processing and then gives the appropriate commands. In modern complexes, interface modules play an increasingly important role, on which the communication capabilities of the controller depend.

The main characteristics of the processor module

When developing a control system it is especially importanttake into account the basic characteristics and capabilities of the microprocessor. As for the main operating parameters of this module, these include the clock frequency, bit depth, task execution periods, memory, etc. But even these characteristics do not always become decisive, since the performance indicators of modern even budget microprocessors are enough to serve most of the production processes. It is much more important to determine the communication capabilities and functions that controllers perform to automate the work of the enterprise. In particular, operators put the ability to work with a wide range of network channels, interfaces, and programming languages first. Separately, it is worth noting the possibility of connecting display devices, controls, modern displays and other components.

Operator panel

Regardless of the characteristics of the controllerTo control its functions, an operator station with a corresponding relay must be provided. Outwardly, such devices resemble a small computer, provided with input and output devices, technological process sensors and a display. The simplest controllers for production automation provide for the possibility of programming through this panel. Moreover, programming can be understood as elementary settings for entry-level commands. The most difficult operator panels also carry out self-diagnostics and self-calibration.

Automation power supplies

The average range of voltages supplyingindustrial controllers, is in the range of 12-48 V. The source is usually a local network at 220V. In this case, not always the power supply unit is located in proximity to the serviced equipment. For example, if controllers are used to automate a boiler house in a metallurgical multistage production, then a distributed power network may be equidistant from several energy consumers. That is, one circuit will serve the boiler for soft metals, and the other for solid ones. In this case, the lines may vary and voltage.

Conclusion

Системы автоматизации рабочих процессов все more closely included in the infrastructure of modern enterprises. Accordingly, controllers for automation systems in various modifications are becoming widely used. By itself, the content of such a device does not require special costs. The main difficulties in working with this equipment concern the quality of programming and optimization of the configuration layout. But at the same time, in order to simplify operator functions, modules are also becoming more and more popular that require self-tuning based on the basic data entered by the user.