Modern production requires increasingquality equipment. It will allow to make the most various elements of any materials. Wood requires the use of a special type of cutters for machine tools. This ensures the quality of the finished product, its durability, and also allows you to give the product an aesthetic look. Mill for the machine on the tree, depending on the configuration, has a number of characteristics. This takes into account the master, performing the processing of the material. More familiar with this tool will allow the classification of cutters for different group characteristics.

General concept

Irrespective of a look, mills for a milling cutter on a treehave a common structure. They have a shank and a working part on which the cutting edge is located. For the manufacture of these components used high-alloy steel, which has high strength.

The shape pattern of the cutter, whether it is a disk or direct itvariety, always exactly verified. Sharpening is performed using special equipment with a very small impact. This improves the functional qualities of the instrument.

It has many varieties of the appearance of the millfor the machine on a tree. This makes it possible to carry out, in accordance with all norms and requirements, the roughing and finishing processing of blanks. This necessarily takes into account the timber litter, its density.

Groups of cutters

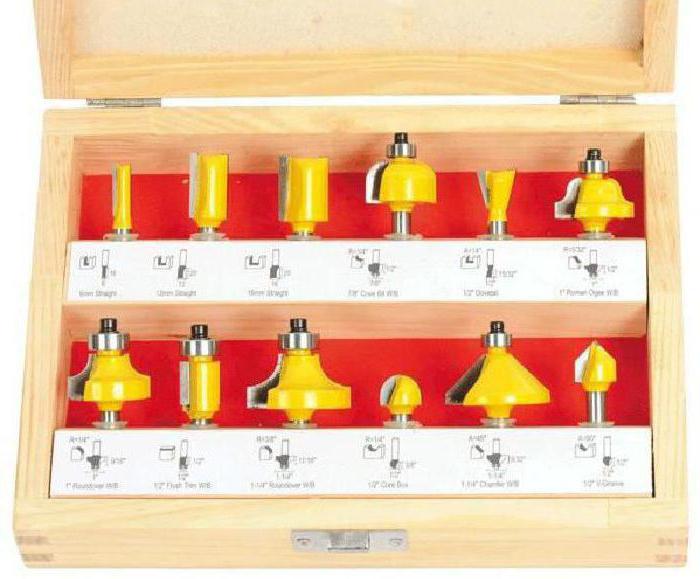

There are two large groups of cutters for wood, which are most often 32, 12 and 8 mm in diameter of the shank:

- mounted

- end

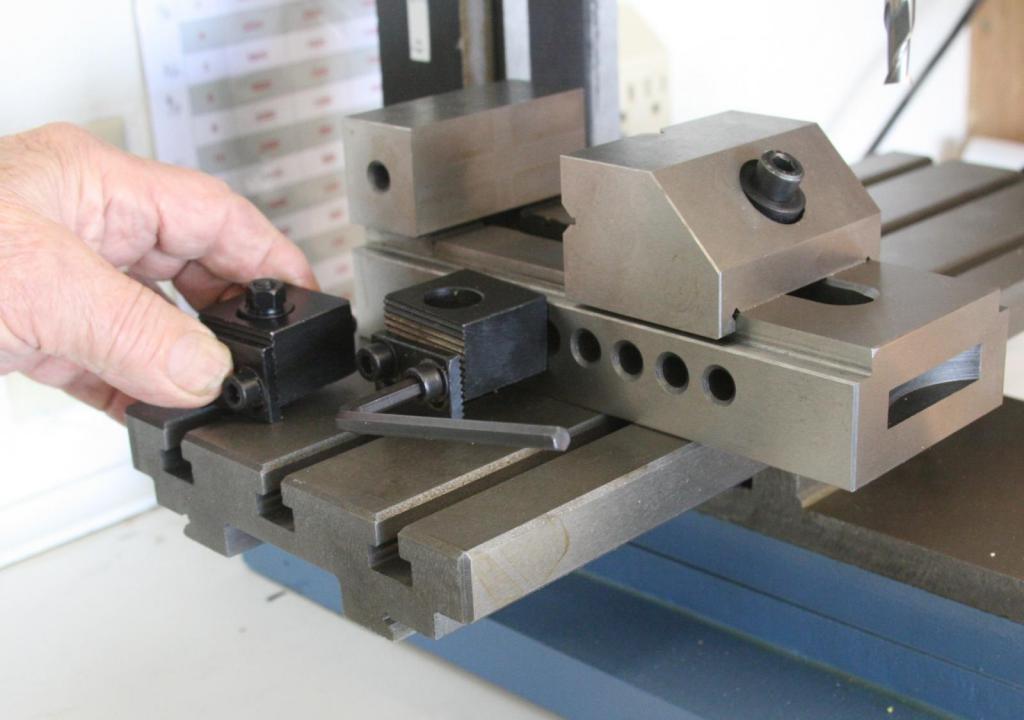

In the first case, they are used under the spindle with a diameter of 32 mm. These are accessories for a stationary mill.

The end or finger cutter 8 mm for wood (there is also 12 mm) is used for the manufacture of parts both on a stationary machine and on manual equipment.

By type of design, these parts can be welded, solid, brazed or prefabricated. And in terms of their functionality, they are divided into disk, ring, cylindrical, and end.

The milling cutter can be used on milling and engraving, horizontal or vertical equipment, on CNC machines.

Tooth design

Cutters on the tree can be divided by typedesigns. They can be whole or combined. If this piece of equipment is small, the manufacturer can make it solid. This will not significantly affect the cost of the item. But larger products have a softer core and a very strong edge.

The advantage of the team cutter for a milling cutter for wood is the ability to choose its diameter to fit the size needed for the workpiece. As the abrasion of a similar element can be replaced with new cutters.

There are only two types of sharpening teeth.It can be zipped and pointed. Often used the first option. These products do not decrease in height when sharpening, which often happens when you sharpen pointed teeth. This is simply unacceptable in the process.

By hardness there is a group of series A forprofessionals and the N series for home use. In the first case, the cost of such a product will be significantly higher. But the durability and functionality of a professional tool is higher. For domestic purposes, more than enough cheaper varieties of such elements.

Product Form

The form is divided into several groups of woodworking tools. They can be slot, edge, combined and figirenye.

The first group is designed for the manufacture of various grooves. To groove include:

- cutter for wood straight;

- fillet;

- constructional;

- shaped

For accurate processing of edges and ends of wood products master applies edge varieties. They can be straight, molding, seam, conical, curly, half-rod.

Combined species contain in theirstructure grooving and thorny detail. They are used for splicing or joining parts. For thin material or work of increased accuracy, use figireny mills. They can be horizontal and vertical.

A separate group are mounted mills, which are used for cutting material carbide inserts.

Equipment for milling and engraving machine

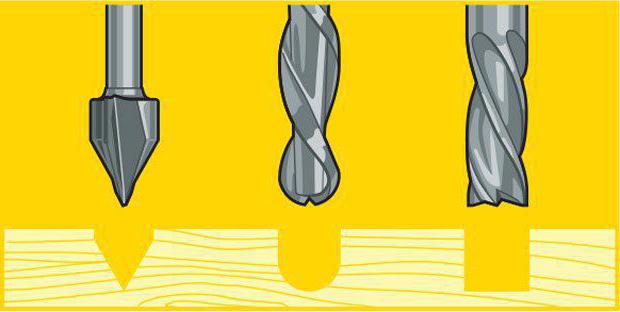

Фреза для станка по дереву представленного типа There are several varieties. It can be end, end, angular or disk. The first two varieties are used to process ordinary material.

End drills have a surface that performs processing in all directions. For flat surfaces, end pieces are suitable.

Corner and disc milling on wood is used for hardwood. Now they have two or three sides, which prevents rapid abrasion.

If on a similar machine it is necessary to make a complex profile, then use shaped shapes. They have ground teeth that provide good surface cleanliness.

CNC machine

Automate material processing allowCNC milling cutters for wood. The participation of the operator is absolutely not required if you install an automatic nozzle changer. And this is despite the fact that even very complex parts will be produced by this method.

Equipment is assigned a program that includesThe description of materials, tools and actions. This equipment allows to achieve high precision blanks. A special program calculates, on the basis of a three-dimensional image, the details of its planar projections. This avoids errors in the calculation.

Moreover, such a program can be installed on any type of machine. Cutters for CNC wood are selected at the same time in accordance with the type of equipment.

Vertical and horizontal machines

For vertical and horizontal machinesThe features of such processing are taken into account when choosing a working tool. If the spindle and nozzle are fixed horizontally, there are certain principles for choosing equipment.

For horizontal surfaces usecylindrical types of mills. When processing narrow, inclined planes, preference should be given to angular varieties. The disk mill on a tree carries out cutting of grooves. If their form is complex, then shaped forms should be used.

In the case where the spindle is placedvertically, the following guidelines should be followed. Surfaces should be machined with mounted end or end mills. If their plane is tilted, angled tips are used.

Key grooves are made using an end mill. Also used shaped forms of the tool.

Care of cutters

All mills on a tree which types were considered above need a constant control from the attendants. You should regularly check the degree of sharpening, as well as the integrity of products.

After work, the cutters are cleaned of dirt,tar and trash. They are stored in a dedicated place. If it is intended not to use these parts for a long time, engine oil is applied to them.

High speed steel allowed to sharpengrinding bars or using a machine. If the nozzle has a plate of carbide materials, to produce sharpening the blades should be only on the machine. Moreover, this equipment should have a low speed.

It is allowed to process only flat parts of the working surface of the cutters. The height identity in the process of doing such work remains in priority.

Having familiarized with such tool as a mill formachine for wood, you can correctly select the desired type for the existing working conditions. Many types of presented products allows the work of the highest complexity. In this case, the finished products are of the highest quality.