Speaking of household appliances, we often hear suchconcepts: "warranty", "warranty seal", "warranty repair conditions", "seal damage" and "failure to service." So what does it look like? How to avoid damage to the seal? In this article we will analyze the questions presented and all that is associated with sealing.

What is a warranty seal?

The seal is used in places where they should notget into prying eyes and hands. Therefore, in order to avoid failures that cannot be restored, due to the excessive curiosity of users, the warranty stickers will seal the new equipment. Why should a seller or manufacturer correct errors that were not made by them, but by the end user who, not knowing the item, decided that he could fix or upgrade the device himself. This greatly facilitates the task and reduces waste.

Where are the seals used?

They seal, in fact, not only household andelectronic technology. Sealing also includes a room into which no strangers can enter, and safes, and various books of accounts and records of materials, money, mailboxes, ballot boxes, and so on. The list of places where warranty seals are applied is quite large. Previously, the seals were wax; on the doors in the old administrative buildings, you can still see a seal with a plasticine filler, on top of which is an impression of the seal. But this method is not reliable enough. Now the warranty seals are made with the logo, with watermarks, specific individual design and so on. All this allows not only to improve the reliability of unauthorized hacking, but also adds corporate identity.

Application specifics

First of all, warranty seals shouldto fulfill its direct purpose - to hide from prying eyes what is under them. Whether it is important information or the motherboard of a new computer, the owner of the seal should know for sure that everything has remained intact. In addition, the seal should not interfere with the user to perform actions with the device, which he is entitled to use at his discretion. That is, it cannot be a giant sticker or panel that will securely close all access to the required ports and covers. Even better, if the warranty seal is invisible at first glance. In this case, an unauthorized access attempt will not be possible to hide by sticking, smearing or rubbing tracks.

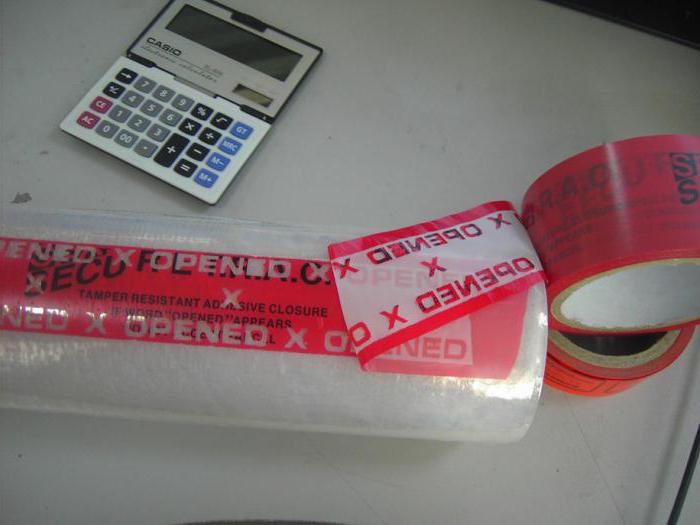

Features and types

Properties that the warranty providesthe seal is caused by the material on the basis of which it is made. They should be clearly visible attempts at opening. In some cases, especially in electronic products, seals have a special indicator that changes color if the equipment has been flooded or flooded. Since water for electrical engineering is very destructive, and warranty repair from one's own pocket is not the most favorite of accidents for the manufacturer, such an indicator plays a huge role. Often such seals are put in order not only to protect the equipment from breaking, but also to clarify in which place it was bought.

Was this device really purchased?in this store, or simply the user decided to cheat. That is why the seals have a distinctive individual design. It is very important that it was difficult to fake it, otherwise the whole point in its use is automatically reset.

Filling production

Types of warranty seals are divided into threeclassifications: those that are made on the basis of paper, on the basis of a film and combined fillings. Paper based seals are resistant to temperature extremes and accidental mechanical damage. Breaking it down without intentional impact is problematic. But under the influence of water, such a filling will collapse. Even if the soaking was insignificant and had no effect on the internal structure of the equipment. Such seals are not recommended to put on items that are stored in a room with high humidity or low temperature. At low temperatures, so-called condensate (water evaporation) forms, which destroys the paper.

In this case, the use offilm. It is much less susceptible to destruction from water. But its minus is the excessive elasticity and loose composition. It can not be glued to the outer joints of the equipment. There is a third option. The combination of paper and film base. Such a filling has all the positive characteristics of both materials, and is devoid of their negative properties.

The seal does not immediately tightly clings tosurface It takes about two hours. But after that it will be impossible to remove it without damage. But this makes it possible to correct the defect, if the seal was originally pasted incorrectly. The price of a universal seal will be somewhat higher than that of a single material, but it fully pays for itself with the quality at the output of the product.