For placing goods in warehouses usedmany different designs. Some of them are frontal pallet racks. Their design is presented as a system for storing goods on ordinary pallets. Since the products are easily transformed, they can be used to store large and small items without pallets. Designs are irreplaceable in warehouse.

For many goods special places are required.storage, so that they do not spoil from various influences. This is what pallet racks are used for. They are placed in warehouses in accordance with convenience and safety so that unloading is carried out quickly.

The concept of

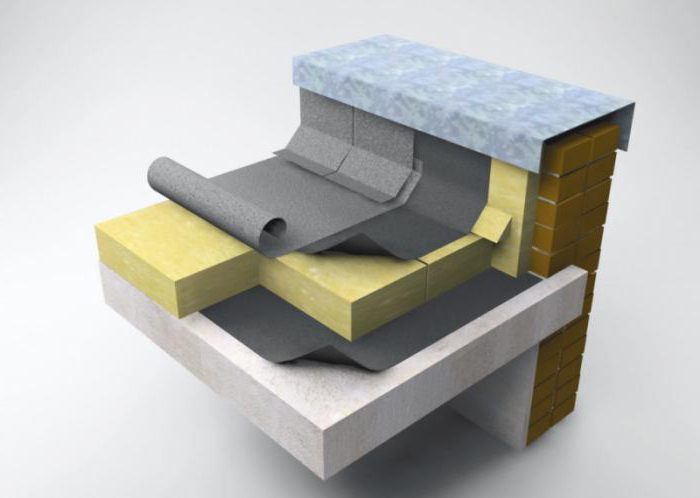

Cargo for easy transportation and movementstored and fixed with straps on wooden pallets. Then they are placed for storage at the warehouse. Shelves are multilevel structures that are assembled from component parts of frames and beams.

The height of the racks can reach 12 meters.The length is determined by the number of sections. They are distributed in 1 or more lines. You can also collect straight and angular structures. Bearing surface includes 2 or more beams. They put pallets loaded. Boxes, boxes and barrels are also placed on pallets. Manufacturers produce various pallet racks.

Equipment

Products have a very simple design:they consist of frames and beams. They are quickly made and spend a little time on installation. Shelves have vertical frames and horizontal beams of different lengths. The package includes clamps, protecting the structure from falling. Racks have a high load bearing capacity.

Отечественная продукция ничуть не хуже по European quality. Galvanized steel is not a sign of unreliable products. S350 steel is used for high-quality shelving, beams are made of St3ps steel.

Scope of use

Frontal pallet racks are used:

- in small warehouses and large enterprises;

- at wholesale bases;

- in the trading floors of shops;

- in production workshops;

- in warehouses for storing chilled or frozen products.

Thanks to such products inside the house, order is maintained that meets safety requirements.

Features

Collapsible products are installedfrontal view of the individual parts. One line will be or two - depends on the type and area of products. The number of tiers and cells is set as needed.

The system consists of:

- Ram, including galvanized rack. Details are fastened with the help of clapboard and bolt elements.

- Beams made of metal profile with hooks. Fastening is provided with special clips.

By applying different sizes of vertical frames,it will be possible to adjust the racks based on the desired depth and height. Section length and load is determined by the length of the frame. To ensure that the load on the front pallet racks is appropriate, special tables are used in the calculations.

Types of racks

Products are insular, which provide a load on 2 sides. There are also wall shelving. All designs are divided into 4 types:

- Narrow passages, since between them is1.5–2 meters. This saves warehouse space. The product is used with the possibility of installing high shelving, with a rich turnover of goods. The disadvantages include the need for expensive storage equipment. And all this increases the turnover.

- Broadband.The distance between them is within 2.5-3.5 meters. The product is considered more affordable and easy to install. Each product is provided with free access. These frontal pallet racks are not economical in space consumption, since they occupy about 40% of the premises.

- Double depths.The product is obtained using shifted structures. This is necessary to increase the usable area, due to the increased density of the arrangement. But in this case, you need a stacker or loader. Such racks are used when the wide passage option does not allow to provide a warehouse with the required usable area.

- Mobile shelving installed on specialmobile devices. Their movement takes place on rails using an electric drive. For mobile structures need additional spending on electricity and the installation of a security system.

Benefits

Front loading pallet racks have the following advantages:

- A wide range of constructs differing in load, quantity and parameters of products being placed.

- There is free access to the goods; no movement of the pallets is required to get the required pallet.

- Use of pallets of different types.

- Can be used to store small items.

- Accounting is provided by labeling storage locations.

- Products are placed in different rooms.

- You can fill the structure completely.

The rack pallet frontal for warehouse is one of demanded and practical. It is perfect for long-term storage of goods.

But the structures have drawbacks:

- It is necessary to equip a wide passage between the racks, which reduces the usable area by 30-40%.

- Additional expenditure on electricity, since the design works on the electric drive (mobile shelving).

Characteristics

Distinctive features have frontal pallet racks. Their technical characteristics are as follows:

- Material - rolled steel.

- The width of the rack - 70, 90, 110, 130 mm.

- Frame coating - galvanized, polymer.

- Rack step - 50 mm.

- The depth of the frame is 800, 1000, 1100 mm.

- Height is 2.2–14 m.

- Types of attachment - hook, bezmetiznoe.

- The load is 4000–25000 kg.

- The length of the racking beams is 1000–3600 mm.

Sizes of parts

Производители создают разные фронтальные pallet racks. Parts dimensions may vary. Choose products based on the floor space, weight of goods, types of equipment. The frames are available in sizes 70, 90, 110, 130 mm. Each design has its own load limit. The load capacity depends on the number of tiers.

Beams are considered an important part of the product.They are 6 species, differing in the height of the cross section of the profile. The greater the length of the section, the lower the load capacity. Each room has its own front pallet racks. Photos presented in the article show how these structures look.

Shelving selection

It is necessary to acquire constructions suitable for specific parameters on the basis of the following recommendations:

- First, you should decide on the load, why the weight of products and goods will depend. According to this parameter, you can determine the dimensions of racks and beams.

- It is necessary to consider the structural details of the traverse -they must have a load hold. The weight of the goods must be equal not only to the strength of the beams; pallets, shelves and frames must be resistant. The type of a rack depends on loading capacity of a cell: frame, pallet or shelf.

- It is necessary to determine the parameters of the cell, which should be suitable for the size of the stored load. Pipes require cantilever products, and boxes require racks with square cells.

At the end, you need to double-check all the selection parameters,increasing the design load by 25%. Safety factor is needed to increase the service life, with maximum loads, the rack will last about 6 months.