Living space is impossible to imagine without a windowwhich is the conductor between the inner and outer space. These elements are made from different materials. But how wooden windows are made, and what types of them exist, read the article.

The advantages of wooden windows

Wood windows have several advantages compared with other materials from which they can be made:

- Have an attractive appearance due towood structure. They are in perfect harmony with wooden furniture and doors installed in the room. Possess a delight and high functional ability.

- Windows "breathe."Only wood has this ability. The tree regulates a healthy microclimate of the room in which windows from it are established. Excess moisture absorbs the wooden surface, with its lack - gives. Air is constantly circulating, even with the windows closed. Its update is due to the micropores of the tree.

- Possess high durability despitevulnerability from fire or moisture. To improve the quality of wood, the manufacture of wooden windows is carried out using various impregnations and compositions that ensure their operation for a long time without losing the original appearance.

- They meet a high level of durability.The quality of the tree from which it is planned to manufacture wooden windows, is estimated at the time of purchase. The most commonly used three-layer glued laminated timber, the minimum thickness of which is seventy millimeters. This bar prevents the deformation of the window and ensures its stability.

- Possess low thermal conductivity due to glue beams. Thermal conductivity depends largely on how the process rules are followed.

- Eco-friendly and safe. Wood meets these conditions - a natural material that does not emit harmful substances.

- Easy to repair. The production of wooden windows favorably reduces the cost of restoration, repair and maintenance.

Russian windows

Have one split part with one box andtwo glazed doors. Made from pine solid with a thickness of the valves of four centimeters. The main drawback is the deformation, since the casements do not completely adjoin the window. Moisture from the street penetrates inside the room, the windows mist over, and condensation accumulates on the windowsill.

Manufacturing of wooden windows is possible with double frames. They are completed with unregulated loops and handles, which is why there is no airing.

German windows

Носят название европейских окон, так как are completed with accessories of foreign manufacturers. These windows compare favorably with the Russians. They can be adjusted according to the height and angle of inclination of the leaf, and ventilated. Characterized by the presence of locking mechanisms.

Finnish windows

They have a wide box and two flaps, whichopen sequentially. The outer flap is made of wood or aluminum, it is with one simple glass, and the inner one - with a single-chamber double-glazed window.

Both doors are interconnected. Open sequentially. Window boxes and shutters are made of solid wood.

Aluminum wooden windows

To extend the life of wooden windowsobbivat aluminum. The bearing part is also made of this metal, but only from the outside it is covered with wood. The design becomes more durable, and thanks to the tree, the appearance remains attractive. The production of wooden windows using aluminum is not common due to the high cost of metal and complexity of installation.

Eurowindows

Consist of a box on the opening window and sash with glass of different types, preventing heat loss. Opening is easy, care is quite simple.

Деревянные евроокна изготавливаются из клееного timber. Its thickness allows the use of a compactor with which the room is reliably protected from drafts. Eurowindows are durable, service life is sixty years and more. With such windows in the house is always warm.

Manufacturing technology of wooden windows

Accurate observance of the sequence of work performed ensures the quality installation of windows The sequence is as follows:

- Glued laminated timber.Wood is cleared of bark, knots and cracks. Boards are sorted by color, breed, structure and other parameters. Then they are impregnated with a protective composition and dried in chambers to eight to twelve percent of natural moisture. After drying, spikes and grooves of microscopic dimensions are cut to join components. The finished timber is sent to a well-ventilated room for storage.

- Frames are made of laminated veneer lumber,consisting of lamellae connected in three layers. The raw material is coniferous wood: larch, cedar, pine. Wooden windows, the price of which is much higher, are made from valuable and more expensive wood species: oak, eucalyptus. The shape of the frames depends on the configuration of windows, which are standard, triangular, arched, trapezoidal.

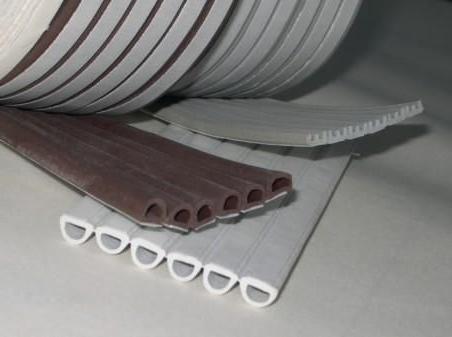

- Glued laminated timber is cut depending on the specifiedsizes and sent for further work with him on the machine. Here are selected grooves and beadings for glass, so that they will not be loosened. Components are thoroughly polished. This provides protection against ingress of moisture. Then they proceed to the assembly of finished blanks using the angular assembly technology of Euro-windows.

- ColoringThis process takes place in a large bath with the addition of a primer solution, where the window sinks. This is done repeatedly, but each layer of primer must dry. After this, the product is painted with a coating or a lightening composition of the desired color.

- Installation of all types of accessories. Its installation is carried out using milling and drilling machines. Accessories imported.

- Glazing.For this work, the construction is placed on a horizontal surface. Install the glass, fastened with beadings with a pistol, in which there are driven studs. Their ends on the surface are not visible, as they bite off, and then polished. The seams are sealed with silicone. The price of wooden windows depends on the material of manufacture and the manufacturer. They are cheaper from pine than from larch and oak. Windows of foreign companies are more expensive than domestic ones. Approximately prices start from 35-40 thousand with installation.

Equipment for the production of wooden windows

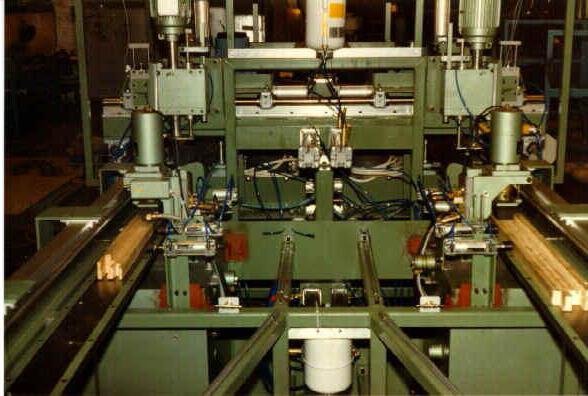

Technical tools are designed toto perform certain window manufacturing operations. Receiving high-quality designs is possible with non-stop and well-coordinated work of all machines, which by functional purpose are:

- Circular and miter saws. With their help, pre-processing of wood blanks is carried out.

- Jointing machine.The manufacture of wooden windows on it is the most dangerous, since during operation the knives rotate at high speed, which do not have protective devices. On this machine, blanks are aligned and right angles are made at the ends.

- Machine reysmusny. Here the blanks are given a certain size. This is the safest unit, as all moving parts are protected by screens, housings or sheets.

- Milling machine.It is designed for processing workpieces knives, rotating at high speed. Observance of caution - the main principle of work on this machine. Here are made spikes and eyelets connecting the sash, pattern and quarters, necessary for the installation of glass or glass blocks.

- Clamps or clamps. Here the blanks are processed with adhesive compositions. After drying, the finished products are polished and prepared for painting using vibratory grinding machines.