In addition, copper cable lugs will help to cope with problems in those

местах, где сеть просто перегревается.Most often this happens where the conductors are connected. Then transient voltage appears. Physico-chemical properties of the material, strength and area of resistance - characteristics that directly affect the magnitude of the voltage. This leads to overheating of the system.

Key features and characteristics of tips

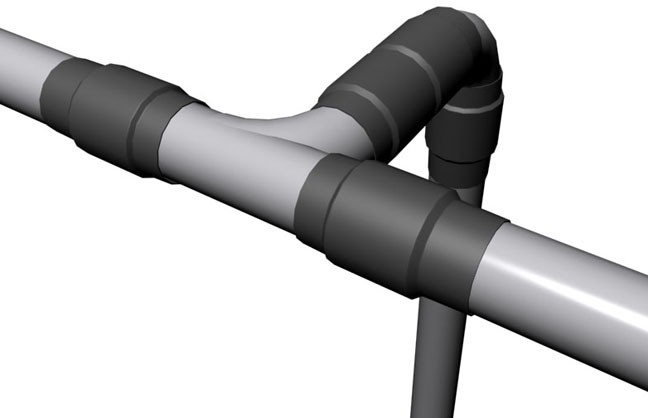

They are special sleeves,which are used to connect in the spring and screw clamp part of the wires, conductors and conductor. Copper cable lugs allow you to increase the contact area. It itself becomes more reliable, the transient resistance rate decreases, an oxide film appears less often on the cable, if it forms at all.

Why do you need this device?

In practice, copper cable lugs playimportant role that is hard to overestimate. Shields, grounding and input systems - these are just a few areas that simply can not do without such products. For the correct and safe operation of household appliances, these devices are also necessary. Fastening is carried out either by soldering or crimping.

Installation and materials

Only reliable, high-quality and durable materials.are allowed to manufacture cable sleeves. There are devices of the combined type, copper, crimped or aluminum. Copper is applied tinned or standard. An aluminum tube and a copper spatula can be combined if a combined cable cable tip TML is created. Such designs are always in demand, especially in domestic conditions.

Soldering is also a fairly well-known operation. In such a situation, molten tin and crucible are necessary. Solder with pre-cleaning the surface of the oxide is also quite acceptable.

In addition, welding has become quite common. It can be thermite, contact or gas. Breaking bolts are also often used to connect several elements together.