There are several connection schemes.electric motors. It all depends on what type of machine is used. In everyday life, each person uses a variety of electrical devices, about 2/3 of the total number of electric motors of various capacities with different characteristics have in their design.

Usually, when devices fail, enginescan continue to work. They can be used in other designs: make home-made machines, electric pumps, lawn mowers, fans. But you need to decide on what scheme to use to connect to the home network.

Motor design and connection

In order to use electric motors for improvised devices, it is necessary to make the connection of the windings correctly. The following machines can be included in a single-phase 220 V household network:

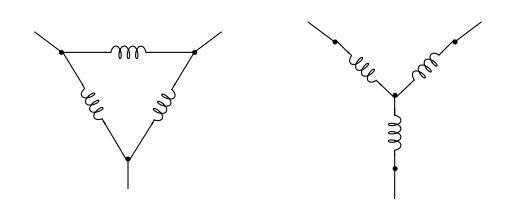

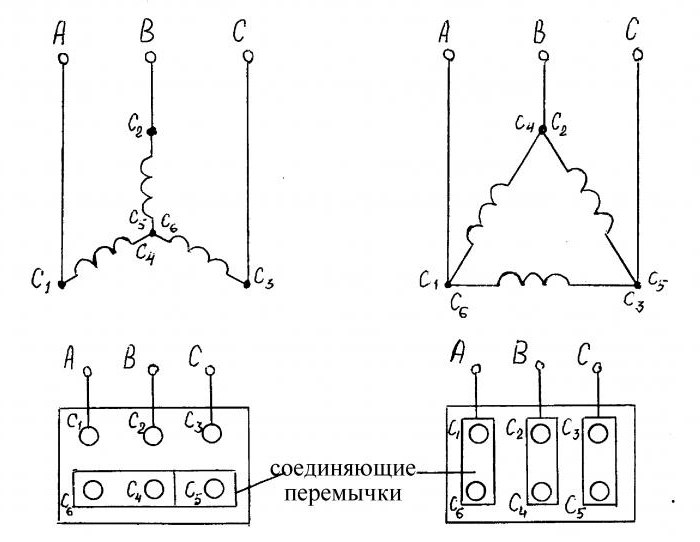

- Asynchronous three-phase electric motors. The motor is connected to the network by a "triangle" or "star".

- Asynchronous electric motors operating from the network with a single phase.

- Collector engines, equipped with a brush design to power the rotor.

All other electric motors are needed.connect using complex devices designed to run. But stepper motors must be equipped with special electronic control circuits. Without knowledge and skills, as well as special equipment, it is impossible to connect. It is necessary to use complex wiring diagrams of electric motors.

Single and three phase network

In a household network one phase, the voltage in it is 220 V.But you can connect to it and three-phase electric motors, designed for a voltage of 380 V. For this purpose, special circuits are used, only to squeeze more than 3 kW of power out of the device is almost unreal, as the risk of the electrical wiring in the house increases. Therefore, if there is a need to install complex equipment, which requires the use of electric motors of 5 or 10 kW, it is better to conduct a three-phase network into the house. Connecting a "star" electric motors to such a network is much easier to produce than to a single-phase one.

What you need to connect the motor

The principle of operation of any electric motorfamiliar to everyone, it is based on the rotation of the magnetic flux. When connecting single-phase electric motors, you don’t really need a theory, so the following knowledge will suffice:

- You should have an idea of the design of the electric motor with which the work is done.

- To know for what purpose the windings are intended, and also to be able to install using the motor connection scheme.

- To be able to work with auxiliary devices - ballast resistances or starting capacitors.

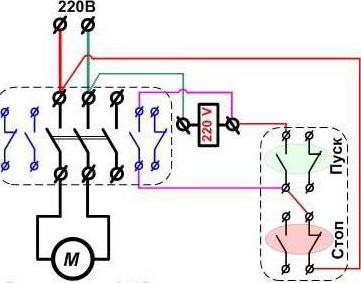

- Know how the motor is connected using a magnetic starter.

It is forbidden to turn on the electric motor,if you do not know his model, as well as the purpose of the findings. Be sure to check what kind of winding connection is allowed when working in 220 and 380 V networks. On all electric motors there is always a metal plate that is attached to the case. It indicates the model, type, wiring, voltage, and other parameters. If there is no data, it is necessary to ring all windings with a multimeter and then connect them correctly.

Connection of the collector motor

Such electric motors are used practicallyin all household appliances. They can be found in washing machines, coffee grinders, meat grinders, screwdrivers, heaters and other appliances. Electric motors are designed for a relatively short operating time, they turn on for a few seconds or minutes. But the motors are very compact, high-speed and powerful. A wiring diagram of an electric motor is very simple.

Connect such a motor to a household network220 V can be very simple. The voltage flows from the phase to the brush, then through the rotor winding to the opposite lamella. And the second brush removes the voltage and transmits it to the stator winding. It consists of two halves connected in series. The second terminal of the winding is fed to the neutral power wire.

Features of inclusion of the motor

Для того чтобы включать и отключать электрический engine, a button with a lock (or without it) is used, but you can use a simple switch If necessary, both windings are separated and can be connected alternately. This is achieved by changing the frequency of rotation of the rotor. But there is one drawback for such engines - a relatively low resource, which directly depends on the quality of brushes. That collector node is the most vulnerable point of the engine.

How to connect a single-phase asynchronous motor

In any asynchronous motor,designed for power supply from a single-phase network of 220 V, there are two windings - starting and working. As a "collector" is used a cylindrical block of aluminum, which is mounted on the shaft. It may even be noted that the cylinder on the rotor is, in fact, a short-circuited winding. There are many schemes for switching on an asynchronous motor, but there are few practical applications:

- Using the ballast connected to the start winding.

- With the included capacitor on the start winding.

- By means of a push-button or relay starter, a starting capacitor connected to the start winding circuit.

A combination of push-button orrelay starter, as well as a permanently switched on working capacitor. Instead of the relay, an electronic key on the thyristor is very often used. Using this switch, a single-phase electric motor is connected with an additional group of capacitors.

Practical schemes

Asynchronous electric motors possesspretty small starting torque. Therefore, it is necessary to use additional devices, for example, starting relays or ballast resistances, as well as powerful capacitors for connecting single-phase electric motors. The windings in the motors are made with the division into several conclusions. If there are three conclusions, then one of them is common. But maybe four or two.

To understand exactly whatThis or that winding is connected to the contacts, it is necessary to study the motor circuit. If it is not there, it will be necessary to make a dial using a multimeter. To do this, put it into resistance measurement mode. If there is a large resistance on a pair of leads, then this means that you measured two windings simultaneously. Typically, the working winding of asynchronous motors has a resistance of no more than 13 ohms. In the starting it is almost three times higher - about 35 ohms.

Для того чтобы подключить при помощи пускателя single-phase asynchronous motor, just enough to correctly connect all the contacts with wires. In order to start the asynchronous, it is necessary to briefly include additional elements in the circuit - a capacitor or a ballast. To turn off the electric car, simply de-energize all windings.

Three-phase electric motors

In three-phase electric motors it is essentialhigh power as well as torque during launch. Connecting a three-phase electric motor is simple only if there is an outlet with three phases of 380 V. But it is problematic to use such motors in domestic conditions, since not all homes have a three-phase network. The windings are connected according to the “star” or “triangle” scheme, it depends on the interfacial voltage in the network.

But in case you needconnect such an electric motor in a domestic network, you have to use a little trick. In fact, you have zero and phase in the outlet. In this case, "0" can be considered as one of the conclusions of the power source, that is, the phase in which the shift is zero.

To make another phase, you need tousing an additional capacitor to shift the supply phase. In total there should be three phases, each of them is shifted relative to the neighboring one by 120 degrees. But to make the shift right, you need to calculate the capacitance of the capacitors. So, for every kilowatt of motor power, a working capacity of about 70 microfarads is required, as well as a starting one about 25 microfarads. However, they must be designed for voltages from 600 V and above.

Но лучше всего производить подключение 380 V three-phase electric motors using frequency converters. There are models that are connected to a single-phase network, and with the help of special inverter circuits, they convert the voltage, as a result of which there are three phases at the output that are necessary to power an asynchronous motor.