Imagine how many there are in the worldmotor transport. Virtually 99% of the world's automobile fleet has a propulsion system - a piston engine. This engine is reliable and has long been used in various types of cars. But back to history. After the industrial revolution, which was caused by the advent of the steam engine, the world rushed to the wheels. The absence of a living driving force, with which quite a lot of trouble, it was very attractive. But if you greatly simplify, the principle of the rotary engine was used even in windmills. It's just that no one thought why.

So, the birth of a more familiar to uspiston engine gave a powerful high-quality jump. Let's recall the principle of work. In the same closed space, the medium and the working volume change. By injecting fuel and air, work is done on the piston. It, in turn, is kinematically connected with the shaft through a complex system of crank-and-rod mechanism. Progressive movement (the piston changing the volume), turns into a rotational motion of the shaft. If you look at the rotary engine, the principle of operation will be somewhat different.

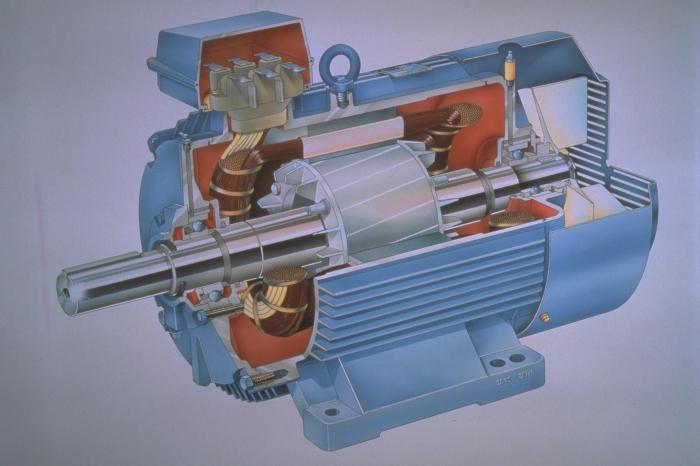

The rotary engine is so called becauseThe main working part is the rotor, not the piston. The rotor in such an engine is presented in the form of a massive triangular-shaped element, inside which there is an aperture with teeth. The stator is represented by an outer shell, lateral rings and an inner shaft with reciprocal teeth markedly smaller in diameter. This is one of the types - the rotary engine. The principle of operation of this device is somewhat unusual and consists in the fact that the rotor rotates asymmetrically relative to the center of the engine. At the same time, three working cycles are carried out in full in a single revolution (relative to the piston cycle). This, if in brief.

If in details, the principle of work is as follows:air intake, compression, fuel injection, exhaust (expansion). Such a cycle is realized in the piston ICE, but only the work performed is comparable to a 6-cylinder piston-type ICE. But why, then, did the principle of the rotary engine not make a revolution? The answer is simple - not everything is as smooth as it looks. This type of DVS was engaged in virtually all world brands, including domestic ones. All were engaged, but it turned out to be implemented in practice in units. It is rumored that Felix Wankel began work on this engine as early as 19 years. But this is unlikely, since at that time the technical development was weak, and the education of a specialist is a luxury and a rarity.

Nevertheless, it is known from history that he gotto work in a printed technical edition. This work became the start for Wankel in the world of technology. It is well known that he began to actively develop this idea, which is why the name of this type of engine - the Wankel engine - took place. Let's return to the question - why rotary-piston engines did not become mass? The answer can be found in the advantages and disadvantages of this ICE scheme.

The advantages of the work that a rotary engine has (the principle of operation described above) are the following:

- high power output;

- ease of construction (in comparison with the piston);

- Absence of limit (dead) points;

- do not need additional elements (crank mechanism).

Disadvantages of this type:

- huge loads on bearings and teeth;

- fast overheating;

- the complexity of sealing individual chambers.

It would seem that the rotary engine principle of operationhas a more successful than a piston engine. Even the advantages are greater than the disadvantages, and they (the advantages) are of great importance. But the developers could not adequately bring the stable operation of the cycles to the working copy. However, there were exceptions. In due time the car Ro-80 has received a rank "the Auto of year of 1987". And this is still an indicator.

Today, the problems faced byengineers, are completely solvable. The parts can be made of composite and extra strong alloys. But automotive manufacturers are not in a hurry to innovate. Perhaps, due to the fact that this type of engine works only with high power, while having a huge expense. Compare this with the price of fuel and reserves of natural resources, and get an excellent perspective, which, probably, is not destined to translate into mass.