For the construction of full verandas and arborsquite a lot of materials and time are required. Therefore, some owners of country houses prefer to build on their sites the usual canopies connected to the house or separately standing.

The construction of such structures is extremely simple. Make a canopy with their own hands will not be difficult even for the inexperienced in the construction of the owner of the suburban area.

What You May Need

The main function of almost any canopy on the countryside is to create a shaded and sheltered area. Under the roof of this design, you can:

- put a table and eat in the fresh air;

- place a car;

- Store and dry vegetables and herbs collected in the summer in the garden;

- arrange a children's mini-playground, etc.

What is a canopy

The main elements of the construction of such a structure are:

- rafter system;

- Sheathing;

- support racks.

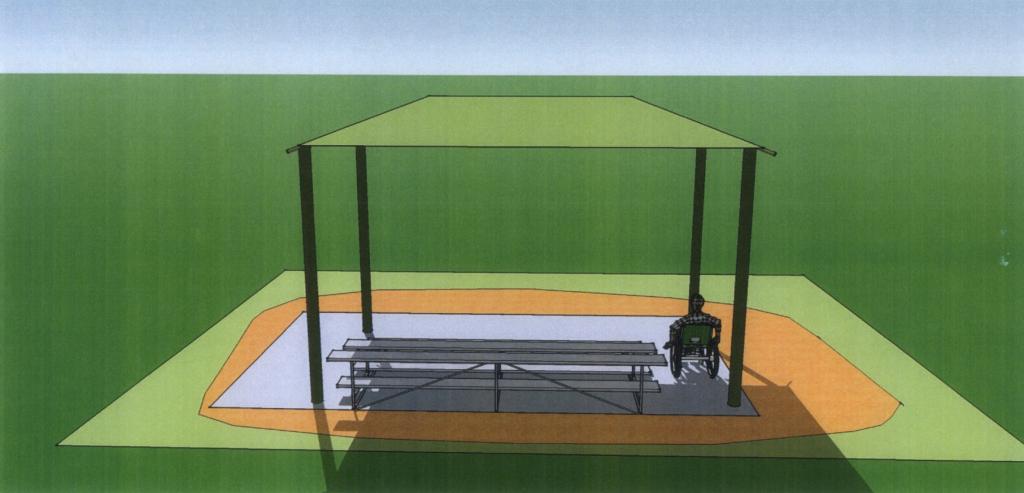

The roofs of the canopies collected by themselves canhave a different configuration. But most often, of course, they make one-sided. The number of shelters depends on where it will be built. There are usually only two supports attached to the house or to some structures of this type of supports. Separately standing awnings have at least 4 racks.

What materials can be used for manufacturing

The frame canopies with their own hands is usually going from

- wooden beams and boards;

- metal pipes round or profile.

Most often in this case for the assembly of the "skeleton" canopy used timber. The roof of this structure can be made of:

- polycarbonate;

- profiled metal sheet;

- OSB plates with roofing felt;

- metal tile;

- slate, etc.

In most cases, the roofs of the canopiestheir own hands in our time are polycarbonate or profiled. Such materials are cheap, easy to handle and look quite aesthetically pleasing.

Advantages and disadvantages of polycarbonate canopies

The advantage of such structures in the first placeis exactly the attractive appearance. Polycarbonate, both cellular and monolithic, can have a variety of colors. A slight drawback of this type of construction is considered only that they let the sun's rays through. That is, the shadow under this canopy will not. But from the precipitation the space below this roofing material is able to protect just fine.

The main stages of the construction of a polycarbonate shed are:

- the erection of the frame of pipes or timber;

- roof sheathing polycarbonate sheets.

Canopies from a professional sheet

The advantages of buildings of this type in the first placerelate their cheapness. Profiled is cheaper than most other roofing materials. Unlike polycarbonate, such sheets can serve not only as good protection against precipitation, but also from the sun's rays.

The disadvantages of corrugated include firstqueue noisy. When it rains, it may not be particularly comfortable to rest under a canopy of this material. Also, the professional sheet is usually used for arranging only large and sufficiently high canopies. This material can be very hot in the sun. And in a small building assembled with its use, in summer days a not too pleasant microclimate can be created.

Collect canopies in the country with their own hands using a professional sheet using approximately the same technology as polycarbonate:

- set the supporting pillars and mount the roof frame;

- perform trim.

The choice of timber and boards for the frame

For this design in the first place should be properly pick up lumber. A long shed in the future will serve only if the bar and board are used to make it:

- well dried;

- not having too many knots.

Humidity lumber used for assemblycanopies, should not exceed 12%. Since such a structure will subsequently be operated on the street, it is better to choose for it a timber and conifer board. Such materials are resistant to high humidity.

How to assemble a frame made of wood

A wooden shed is erected in the yard with their own hands, usually using this technology:

- supports are installed;

- strapping top strapping.

At the final stage, the rafters for roofing material are mounted.

Next, we consider a method of making a canopy with your own hands according to the drawing below.

To build the frame of such a construction will need:

- timber section of 100x100 mm;

- board 100x50 mm.

You will also need to prepare galvanized corners. To begin with, when assembling the “skeleton” of a canopy in the country, they install support stands with their own hands. The following technology is used:

- make a marking on the place chosen for installation of a canopy;

- 4 pits are dug along each of the long sides of a future building with a depth of 70-80 cm;

- put some sand into the pits;

- process that part of a bar which will be in the subsequent underground, drying oil or the fulfilled lubricating oil;

- install the columns vertically using the level in the pits;

- poured into the pit concrete mix.

For frame supports, you need to use a bar of differentlengths On the one side of the future overhang, supports are longer, on the other - in short. Cement mortar for installation of canopy supports use cement / sand / crushed stone prepared as 1/3/4.

After the concrete supports mature, i.e.about 2 weeks after pouring, proceed to the assembly of the roof frame of the canopy. At the first stage, the supports of each side are joined into a single structure. For this:

- fill the board between the posts, along their upper edge from inside the canopy;

- switch to the other side and repeat the operation;

- fasten each pillar to the beaten board with booms;

- the same boards are filled from the outside of the future shed also on both sides.

Next, proceed to the actual assembly trusssystems of wooden canopy do it yourself. To do this, first on the elements packed in the previous step, mount the rafters. Lumber for feet use a length of 40-50 cm longer than the width of the canopy. After the rafters are installed, they are joined by boards along the contour of the future roof.

How to sheathe canopy professional sheet

To mount this roofing material, of course,follows with the observance of certain technologies. First of all, the roof of the roof should be sheathed with a waterproofing device. If desired, however, this step can be skipped. Sheeting in itself well enough retains moisture.

Mounted this material in compliance with such rules:

- install sheets on the roof of the shed using special roofing screws;

- it is desirable to fasten them with rivets between them;

- the overlap between the sheets on a single canopy without waterproofing should not be less than 200 mm;

- screws for fastening sheets are screwed into the hollows between the waves;

- At least 6-8 fasteners are used per sheet.

After finishing the lining, assembled with your own hands, the canopy of corrugated board can be used for its intended purpose.

How to mount a metal frame

For such a "skeleton" canopy, for example,use a profile pipe with a section of 50x50 and 40x40 mm. In this case, you will also need a similar material 30x30 mm under the ribs. These canopies are made of metal with their own hands, usually using welding. But if there is no suitable equipment in the farm, bolted connections can be used.

Metal, if desired, will not be too difficultmake including a frame for a beautiful and durable arched canopy and sheathe it in the subsequent polycarbonate. But in this case you will have to purchase or rent such equipment as a pipe bender.

The arched frame of a canopy is made of polycarbonate according to the following technology:

- pipes of 50x50 mm are cut according to the height of the building;

- welded to their lower end of a plate of thick sheet metal with an area of 200x200 mm;

- pipes 40x40 mm are cut to the width of the canopy and arch arch;

- weld curved pipes into trusses using 30x30 mm belts;

- weld on the farm to each pair of racks;

- install pairs along the canopy and connect them using a 40x40 mm pipe.

Polycarbonate Sheathing

The roofing material on the metal frame thus assembled is also fixed in compliance with certain rules:

- arrange the sheets on the farms in such a way that the stiffening ribs run along the slopes of the roof of the shed;

- fastener holes drilled exclusively between stiffeners;

- for fastening the sheets to the trusses use special screws with thermal washers;

- the diameter of the holes for fasteners in the sheets should be slightly larger than the cross section of the rods of the self-tapping screws;

- the first and last screws are fixed at a distance of no more than 4 cm from the edge of the sheets;

- Intermediate fasteners on the sheets have a step of 40 cm.

The holes for fasteners in polycarbonate should be quite large due to the fact that this material is capable of rather widening or narrowing with changing ambient temperature.

After the canopy will be sheathed, you should, among other things, additionally glue the open ends of the cellular polycarbonate with tape. Otherwise, water will flow inside the sheets later.