Country house owners often build stoves.For many hosts, this design not only serves as a source of heat. The furnace for a large number of people is a tribute to Russian traditions. In addition, the design performs aesthetic functions. So that it becomes not just an interior item, but an element of decor, appropriate finishing is necessary. Tiling brick kiln is the most optimal solution to the question of the external design of the structure. Next, consider how this is done.

Material

On the market today, the range of coatings is prettywide The most popular material for facing the furnace is ceramic tile. It has many advantages. The technology by which the furnace is tiled, simple enough and clear. Therefore, all the work can be completely done independently.

Material Advantages

Facing the stove tiles will allow several times to increase the heat capacity of the structure. Material for finishing has the following advantages:

- Strength.

- Flame retardant.

- Eco-friendly.

- Stiffness

- Durability.

Quality tile over time does notwill lose color and brightness. One of the undoubted advantages of the material is the simplicity with the care. In addition, the tile is treatable and easy to install.

Classification

Материал выпускается нескольких видов.Lining the furnace with clinker tiles is very popular. It consists of various components: fireclay, dyes, clay and other things. It looks like porcelain. However, it has a monolithic structure. Often carried out lining the furnace tiles "majolica". It represents the pressed elements covered with glaze on top. Terracotta tiles are also popular. It looks like a majolica. The difference is that "terracotta" has no glaze. You should also be aware that the thickness of the material has a direct impact on the strength and thermal conductivity of the finish. As for the size, the square is considered optimal, the side of which is equal to 12 centimeters. It is extremely undesirable to apply a tile to finishing. This is due to the fact that the material does not tolerate exposure to high temperatures and eventually begins to crack and split off from the surface.

Tiling the stove with their own hands: preparation

This stage, in turn, can be divided into threemain stages. The first will be the preparation of the furnace surface, then the selection of tiles and tools. The final stage is the choice of glue. To work with the base you will need:

- Brush (metal).

- Bulgarian and abrasive wheel.

- Level.

- Brush.

- Plumb.

- Sand.

- Water.

- Cement.

- Capacity (the solution will be mixed in it).

- Metal grid.

- Nails with washers, hammer.

The oven surface is cleaned with a brush fromformer plaster, dirt, dust. Next, using the grinder, should be done jointing (shallow) seams of masonry. Next is the plastering of the surface. The solution is mixed in the tank. The sand in it should be 3 parts, cement - 1. The solution is well mixed. It should not be lumpy. For greater reliability, the grid is fixed on the surface of the furnace. Fixation carried out in the embroidered seams with nails. After that, the surface should be moistened with plenty of water. For convenience, it is better to use a brush. Using a spatula, the solution is applied to the oven. The surface must be flat. To do this, use the level and plumb. The required number of tiles is calculated in accordance with the area of the furnace. The material is purchased with a small margin (for scrap and pruning).

The choice of adhesive composition

The mortar, like the tile itself, must be stable.to elevated temperatures. You can buy ready-made glue. For example, customers speak well of Plitonit-Super Kamin and Skanfixsuper solutions. You can use self-made clay or sand-cement mortar.

Technology

Before the ceramic tile facing will be carried out, the following tools should be prepared:

- Solution.

- Tile.

- Rubber hammer.

- Tile cutter

- Mix for grouting.

- Plastic crosses.

- Dry and wet rags.

- Level.

- Wooden lath.

- Spatulas (notched, rubber and flat).

Перед тем как будет проводиться облицовка печи tiles, the surface should be well dried. At the bottom is mounted wooden lath. It is fixed so that the distance from the floor to it is equal to the width of the tile. The evenness of the slats is checked by level. She laid out the second row from the floor. Begin to glue the elements should be from the corner. The rail is necessary to prevent the facing from being skewed, since the floor is not always perfectly horizontal. Finishing material with hot melt is applied to the surface and gently pressed by hand. For better fixation, the elements are lightly fitted with a rubber hammer. Excess glue is immediately removed with a damp cloth. To make the seams even, plastic crosses are inserted between the tiles. Before grouting, they will need to be removed. If irregularities or distortions appear, they should be immediately removed (until the glue has dried). The bottom row fits last after removing the slats. If necessary, adjust the tile to the size should use tile cutter.

Masonry completion

After 3-4 days after drying glueThe mortar needs to be filled with joints between the elements To do this, use a special grout. The mixture is applied with a rubber spatula. Excess grout removed immediately. After the solution dries, the final cleaning of the lining is carried out. For this, dry and wet rags are used. After several days you can use the stove.

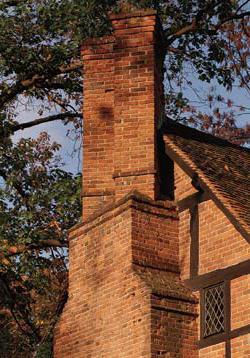

Features of terracotta tiles

Для начала, следует сказать, что этот материал indispensable for the walls of the chimney, fireplace, barbecue and other similar structures. You can use terracotta tiles on masonry with rough rough and used bricks. With the help of finishing material, you can not only correct the flaws in the work and put in order the appearance of the structure. Terracotta tiles can be used to create true masterpieces.

Material laying

Facing the kiln with terracotta tiles begins withplacement of corner elements. Horizontal aligns with the level. Elements made according to the proportions of a one-and-a-half or single brick are fixed so as to imitate the laying. Due to the natural play of shades (from ocher-fiery to straw), to prevent the appearance of clearly distinguished color spots on the lining surface and to achieve a distribution of tones as close to natural as possible, it is better to carry out the work, revealing all the packages with the material at once and using in turn 1-2 items from each box. The back corrugated side of the material provides durable and reliable adhesion to the glue and the base. If heat-resistant reinforced glue "Terracotta" will be used as a fixing compound, it is necessary to wet the surface of the kiln before applying it. Heat resistant mastic is a ready mix. It is very easy to use and has a high degree of reliability. Paste retains its performance properties even when the temperature rises to 1100 degrees. This material provides an absolute advantage over other compositions.

Mastic application

Stir well before use.solution, achieving a consistency of thick cream. If it is more liquid, then you need to add some sand. Mastic is applied to the base and tile. Using a comb spatula, the mixture should be evenly distributed over the surfaces. In order to maintain the required distance between the elements, drywall pieces are inserted, the thickness of which is 9.5 mm. They will need to be removed no sooner than four hours after the work is completed. Finishing should be carried out without breaks and smoke breaks, since the mastic hardens quickly enough when interacting with air. It is also recommended to cover the container with a lid during operation.

Finally

As can be seen from the material, it is quite easy to veneer the stove with tiles. The price for the services of masters starts from 600 rubles / m2. However, you can save considerably if you do everything yourself. The main thing is to choose the right tile, glue and correctly prepare the base.