Несмотря на развитие технологий и материалов, Linoleum was and remains the most popular floor covering. This material has proven itself for many years as an excellent floor covering for commercial premises and offices, as well as ordinary apartments or houses.

Данный материал можно быстро и качественно lay, capturing a large area for the minimum amount of time. If the premises are under repair, the linoleum is also quickly removed. This coating is easy to clean, withstands heavy wear and does not lose its beautiful appearance. Today you can buy types of linoleum, imitating different textures. Also offers a wide range of colors.

Во времена Советского Союза данный материал released in fixed sizes with a width of 1.5 m. Today, the choice of measurements is more - you can buy a coating width of 3 or even 5 meters. Despite this, you often have to glue two pieces of material together. Many would like to learn how to glue the linoleum butt at home. Consider several technologies.

Why, when and why is it necessary to glue the joints of linoleum?

This flooring is very hygienic andquite mobile in the matter of replacement. Often it is used for finishing floors in kitchens and corridors - these are the places where you need to clean up especially often. Also, these rooms are places with high levels of humidity and are characterized by rapid temperature changes. The interiors of the apartments in the houses of the old buildings and the layout of the rooms makes glue the joints of linoleum.

Linoleum bonding technology

There are two options.So, you can apply cold welding, which is applied with the help of special adhesive compositions, or the hot version - here a special cord with a hairdryer solders the joints between them. Additionally, there are still subspecies. For example, there is nothing easier than glueing linoleum on the floor with double-sided tape.

Hot way

При помощи данной технологии стыки линолеума glued in commercial premises. Here it is necessary to have special equipment for welding. Also need a special cord. Instead of welding equipment, you can use a heat gun.

Итак, в месте стыков укладывают шнур.Laying width should be 2-3 mm. Then, using a hair dryer, which was previously heated to 500 degrees, the wiring is simply soldered to the surface of the linoleum. It should be borne in mind that one cord should be no longer than half of the soldered part. The second piece of cord is put on soldered with a small margin of 2-3 cm.

Высокие температуры позволяют максимально efficiently and hermetically solder the material of the cord in the linoleum. To remove it, experts prefer to use a special tool for gluing linoleum.

Cold welding

This is a great way to perform a surgery.gluing joints with their own hands. Cold welding is often used in everyday life and is considered very popular for such tasks. Why is the process called cold welding? It is carried out by gluing the flooring with an inexpensive glue for linoleum without the need for “violence” over the material at high temperatures.

How to glue butt linoleum cold welding

Its edges should be cut off as accurately as possible andsmooth. Then they are superimposed on each other so that one joint covers the other about 3 cm. It is important that they are clean and dry. Before you glue the linoleum on the floor, you need to apply paper tape to the material - it will reliably protect the decorative surface from aggressive glue. It also acts as a label for the bonding zone. Scotch tape is applied not only on the top, but also on the bottom.

Next, the upper and the lower are cut off simultaneously.strip of floor material. The remaining trim should be removed. Then both are rolled together using a special roller at the joint, so as to level it into one level.

Cons of cold welding

Cold welding is a very effective glue, howeverYou should not use it on linoleum, which have a soft base or insulation. In this case, the glue will not help to achieve the most accurate joining. The stitches will be very noticeable, and their appearance will become unaesthetic.

Selection of glue

In the process of using cold welding, it all depends on the materials that are glued together. There are several types for different situations:

- Glue "A" has a liquid form and is suitable for working with rigid linoleum.

- Clay "C". It creates a special layer on the surface of the seam and is used for gluing joints up to 4 mm thick.

- Glue "T" can glue polyester materials.

Required Tools

Let's look at what tools canwould need. Selection is based on the type of linoleum. To work on the hot technology will need scissors and edging for a smooth cut. Further, in order to apply the material, it is worth preparing a spatula, brush or roller.

Professional advise

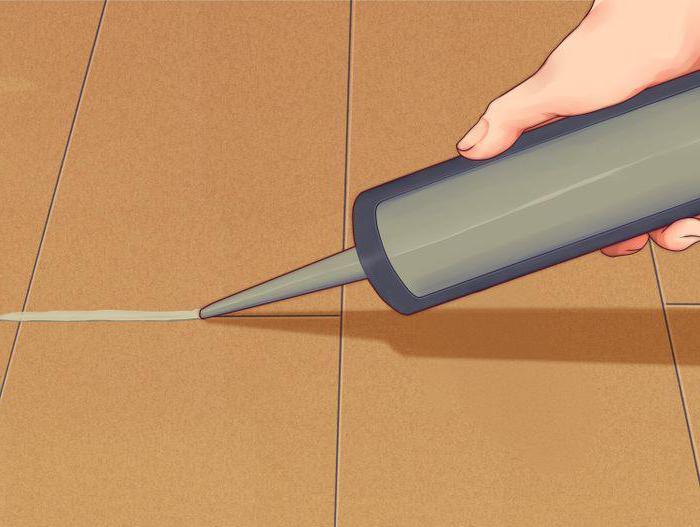

The needle from the tank with glue during cold welding should be fed as deep as possible inside the seam.

As you can see, the procedure is simple and affordable.everyone. As a result, the floor will take a beautiful aesthetic look. There is nothing better than well-laid linoleum. Gluing the seams will give the floor an even more aesthetic look.