Despite the variety of modern buildingmaterials, concrete continues to maintain a leading position among competing options, as it has such important characteristics as strength, reliability and durability. It is an integral component of solutions for the creation of foundations, masonry walls, plaster and other construction operations.

Concrete, frost and water resistancewhich are at a high level, is the key to quality and excellent performance indicators of any design. These properties mean the ability of concrete products to withstand the negative effects of such natural phenomena as moisture, water and negative temperatures.

Currently there are various brandsconcrete on frost resistance and water tightness, differing in quality, the price and technological capabilities. This classification helps to select the optimally suitable material for the creation of structures intended for use in certain conditions.

Brand concrete for water resistance

Determination of waterproof concretecarried out by direct and indirect indicators of its interaction with water. Direct indicators are the concrete grade and its filtration coefficient, and indirect indicators are indicators of the water-cement ratio and water absorption by weight.

In private and commercial construction practice,to find out the water resistance of concrete, pay attention to its brand, and other criteria are important mainly in the production of this building material.

Characteristics of concrete grades in terms of water resistance

When choosing the required brand of concrete forperformance of a certain type of construction work is guided by digital indices, standing after the letter W, characterizing the degree of interaction of the material with moisture and water. For example, the lowest water resistance of concrete and, therefore, low quality of the brand W2. Solutions on this basis are categorically not recommended for use in environments even with a low level of humidity.

Normal degree of permeability for concretebrand W4. This means that this composition has the ability to absorb a normal amount of water, so its use is possible only if good waterproofing is provided.

On the next position in the quality scale is the brandW6, which is characterized by low water permeability. This concrete belongs to the compositions of medium quality and low price category, which explains the popularity of its use in construction.

Concrete brand W8 has a low permeability, as it absorbs moisture in the amount of only about 4.2% of its mass. It is a better and more expensive option than the W6 brand.

This is followed by concrete grades with indices 10, 12,14, 16, 18 and 20. The higher the digital value, the lower the permeability of the material. According to this classification, W20 concrete is the most waterproof, but it is not often used because of the relatively high price.

Practical use of certain grades of concrete for water resistance

For high-quality and durable exterior finishwalls, casting of homestead plots and paths should also use concrete with maximum water resistance, as these areas will be systematically exposed to the negative impact of external weather factors.

Concrete additives for waterproofing do it yourself

The need to use high qualityconcrete mixtures in the production of certain objects or their elements is obvious, but this requires significant financial investments due to the high cost of such materials. But what to do if the budget for construction is limited, and the violation of the technological process is unacceptable? The answer is simple: you can use a compromise option, namely to increase the water resistance of the concrete yourself.

Today there are several effective waysincrease the resistance of concrete mixes to water, but the most popular won two of them: by eliminating the shrinkage of concrete and using a temporary impact on the concrete composition.

Eliminating the process of shrinkage of concrete

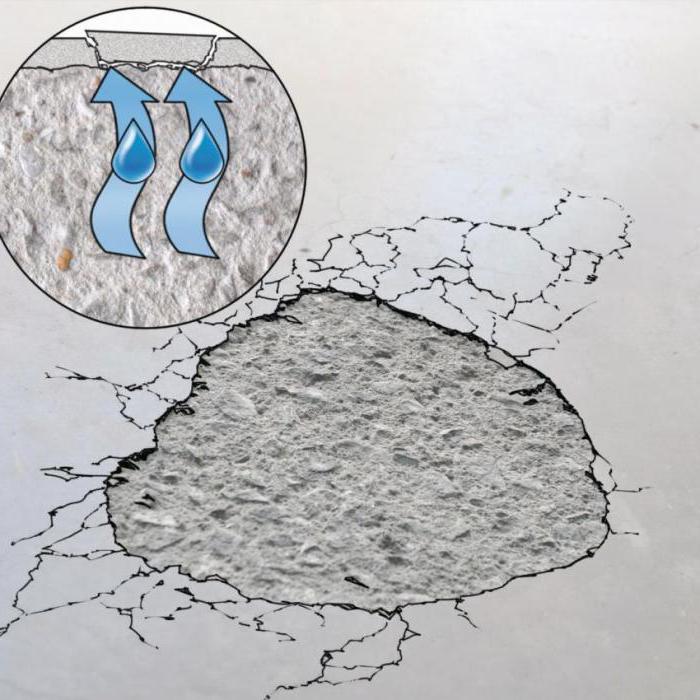

Concrete low and medium grades are sufficientporous materials that easily absorb moisture. This negative property is enhanced in the process of shrinkage of the solution during freezing. Thus, it is possible to improve the quality and impermeability of the concrete mixture by reducing the degree of shrinkage.

To achieve the desired result will help an integrated approach:

- It is necessary to use special additives inconcrete for waterproofing. The principle of their action is that when the solution hardens, they form a protective film that prevents it from shrinking. Today, various concrete additives for waterproofing are presented on the market, and although the task is one, each individual variant has its own characteristics, so you should carefully read the manufacturer's instructions before buying.

- Помимо того, что добавляют в бетон для water resistant special additives, it is also recommended to pour water. This procedure is performed during the first four days with an interval of 4 hours. Next, the concrete structure should dry in natural conditions.

- With the rapid evaporation of moisture from the solution atFreezing also causes undesirable shrinkage. To slow down this process, after pouring the concrete structure, it is necessary to immediately cover it with a special film, under which condensate will form, which prevents shrinkage and contributes to an increase in concrete strength. The coating is positioned so that it does not touch the fill. Along the edges leave small gaps for ventilation.

Temporary effects on concrete composition

Frost resistance of concrete

Determination of the frost resistance of concrete is carried outby laboratory tests using two methods: basic and accelerated. If the research results diverge, the final version will be considered the data obtained using the basic method.

Study of the resistance of concrete to low temperatures

For example:

- in the presence of the highest possible level of groundwater;

- during seasonal thawing of permafrost;

- when exposed to precipitation;

- in the absence of periodic water saturation, when the concrete is reliably protected from groundwater and precipitation.

Classification of the level of frost resistance of concrete by brands

To determine the level of frost resistance of concrete, digital indicators are used from 25 to 1000. The greater this value, the higher the quality and reliability of the material.

Concrete selection rules

Выбор необходимой марки бетонных смесей по frost-resistant properties should be carried out taking into account the climatic features of the area, as well as the number of freezing and thawing cycles during the cold period of the year. It should be noted that the most frost-resistant concrete with high density.