Many prefer to have a personal boat. Since the brand is pretty much worth, homemade boats made from plywood can be a great way out.

On the ship, which will be discussed, it can comfortablyaccommodate three people, besides, its weight is small, like an ordinary kayak. It is suitable for fishing, and for walks with friends or family. If necessary, the boat can be equipped with a motor or a sail.

Plywood is a durable material, so self-made motor boats made from it can accelerate to very decent speeds, while being stable and safe.

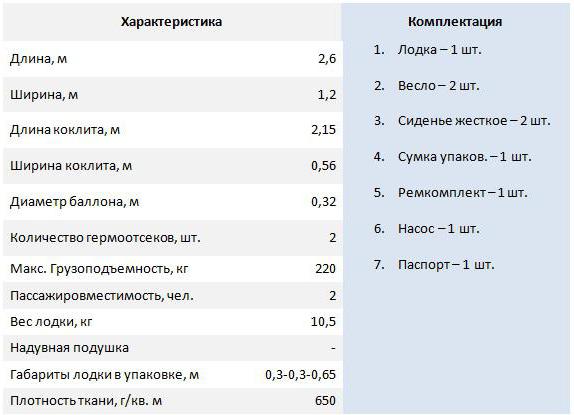

Parameters of the future boat

The boat in question will have a length of 4.500 mm, its width is 1050 mm, and the depth is 400 mm. Such parameters allow the boat to be used universally.

Material for manufacturing

To make the case durable and easily withstandload, it is better to choose a three-ply plywood that does not have knots, with a thickness of sheets from 4 to 5 mm, and necessarily impregnated with glue on a resin base. From this material, excellent homemade wooden boats are obtained.

Plywood is used in shipbuilding everywhere. After all, from thin layers of plywood, connected with resin glue, you get a very strong veneer that can withstand huge loads.

What the boat consists of

The main element of the whole construction is the keel.It is like the ridge of a boat and to it is fastened on one side the stem that forms the nose, and on the other side the atersteam forming the stern. These structural elements are responsible for the longitudinal stiffness of the ship, so that the homemade motor boat from the plywood was strong.

Transverse stiffness is provided by frames. Their lower part, which will become the bottom, is called a flirtry, and the two upper lateral parts are called futoks.

When all the elements are assembled and securely fastened, the frame is covered with plywood. After that, to give the structure more rigidity, the top of the stems, as well as the frames, are fixed with boards-boards.

For plywood casing, you need to useOne-piece sheets that will completely cover the necessary plane. Only so self-made boats and boats will have a minimum number of seams. The plywood of the plating lays on the frame, forming smooth transitions of lines and creating a streamlined boat shape. There is a minimum kink in the waterline only on frames 2 and 4.

Materials for the construction of boats

- Plywood 3 sheets 1500x1500 mm.

- The boards are pine 3 pieces 6.5 m long and 15 mm thick.

- Two boards for the keel and falshkilles, the length of which is 6.5 m and the thickness is 25 mm.

- One board for making a stern oar, the length of which is 2 m.

- Board, the thickness of which is 40 mm, and the length is 6.5 m (for making frames).

- Two planks on oars and staves, length 2 m, thickness 55 mm.

- Light fabric 10 m, which will cover the body.

- 1 kg of slaked lime.

- 7 kg of wood tar.

- 4 kg of natural drying oil.

- 2 kg of oil paint.

- Nails in length 75, 50, 30 and 20 millimeters.

- Oarlocks for oars with bolts and fixings.

We manufacture details

We create frames, they need to be drawn on plywood.To ensure that everything was perfectly smooth, apply paper millimeter. The boat is made by hand with the drawings that will be presented here. Let's start with the first one.

The first step is to draw a vertical axis ordiametral plane - DP. Then horizontal lines are drawn so that the PD divides them in half. There should be nine of them, and the distance between them is 5 centimeters. Then, on these horizontal lines, marks are put on which the bends of the boat itself will be created. Make them better with the help of a metal ruler, bending it over the marks. So made a boat with his own hands will have the perfect shape.

Now create the inner contour.From the lower horizontal line upwards two more lines are drawn, parallel to it at a distance of 60 and 75 mm. After that, 130 mm is measured from the external bend to the axis on frames No. 2, 3 and 4. And on frames No. 1 and 5 in the same places they lay 100 mm each, because they are extreme and are going to narrow. Thus, we draw the internal tide point on the timberbombs, after which we draw down a line from it to its upper cut.

We build the internal contour of phutox

From the outer part of the inside is deposited 40 mmthe entire length. And where flortimbers join the futoxes, you need to make it a little wider so that the design is reliable. Thanks to this element, homemade motorboats have the necessary margin of safety.

When done, the drawing needs to be checked,bending it along the center line. If all the contours coincided - well. So, you can make patterns of cardboard for further transfer of the image on wooden blanks. In the case when there are inaccuracies, you can use the half, which is ideal, and make patterns using it, first applying one side and then the other. The drawings must have perfect symmetry, otherwise homemade plywood boats will not be strong and stable on the water.

How to transfer an image from templates to the tree

When the templates are ready, we apply them to the board, whose thickness is 40 mm. The location should be in the direction of the fibers of the tree, you need to calculate everything so that they are cut as little as possible.

When drawing patterns and cutting themfutoksov, it is worth to leave the stock, making them a little longer than the planned size. Making homemade boats of plywood, make drawings in good faith, taking into account all the nuances! Presented drawings will help you with this. Notice the margin in the side view drawing, as well as in the illustration of the frame, which is depicted a little higher. Such a stock will avoid errors when assembling the boat frame.

When florimbers and futox are ready, they are put ondrawing to mark all overlaps in the joints. Mark everything with a margin of a millimeter. This is done so that in the process of fitting the parts can be more carefully combined.

When everything fits perfectly, you can mountnailing. They must pierce both parts of the frame through. Bend the end of a sharp end or rivet. Thus, your homemade plywood boats will be even more durable!

Since the plating is nailed to the futoxes No. 2 and 4, they should be made 40 mm thick, and for the rest, you can take boards thinner - 30 mm.

Stem Material

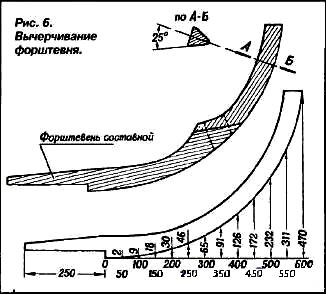

If you want to get a good andstrong stem, take oak or elm to make it. It is desirable that the workpiece has a bend in the shape of a stem. If it cannot be found, then it is made of two parts, as shown in the figure. First, its shape is cut out, and then the edges of the side edges are turned at an angle of 25 degrees to the axis of the boat. Before you make a boat, you need to study in detail the drawings of boats of the same design.

Make the keel

It is necessary to take a board, which is 25 mm thick, and 3.5 m long. On its surface two lines are drawn, the distance between which is 70 mm. According to him and make the future keel.

Side boards

Two boards are covered in order to get perfectly smooth boards with a width of 150 mm and a length of 5 m.

Transom

The rear wall of the stern, where the motor is attached, is called a transom. It is made from a board with a thickness of 25 mm. A bar is nailed to the top for greater strength of the vessel frame.

Boat frame

Homemade boats made of plywood are going toWorkbench where keel is set. To it, on the one hand, they connect the stern bush and the transom fixed on it, and on the other, the bow. The remaining parts of the hull of the boat, such as studs and frames, are connected with the help of small nails, screws, rivets, in a word, which, according to the master, will be safer to hold.

Everything is checked in detail to excludeframe distortions. Especially you need to ensure that the stem and transom were in line with the axis. It is very easy to check this: on top of them they fix a rope in tension and look so that this line fits perfectly with the axis of the boat. Before creating a ship, it is advisable to look at home-made boats made of plywood of various designs, the drawings of which are widely represented in ship-making magazines.

All joints should be laid with a cloth soaked in resin. Fasteners with a cloth connected with nails. Drive them in so that they come out on the other side by five millimeters.

Frames are fixed on the keel.They make grooves in which the keel is firmly fixed. Cut them to half a millimeter smaller than necessary, so that in the case of a bevel there was an opportunity to fix everything. Generally, when making homemade boats and boats, it is worth leaving gaps in all the joints in order to customize the parts already on the assembled frame for its perfect shape. And after that, all the connections are firmly fixed with nails, as described above.

Plywood boat trim

For covering boat overturn and maalkuatframes. That is, level their surface so that the plywood fits perfectly. To do this, take a metal ruler or something flat and elastic and apply to the surface of the frame. So it will be perfectly clear where you need to shoot the material.

To plywood well bent, it steamed.It is necessary to pour water into the trough and make fire under it. A sheet of plywood is placed on top. The water is steaming it, and it becomes more malleable. There is no perfect pattern on which to trim the skin, although many boat drawings represent them. In any case, these are only approximate forms, because everything is customized individually.

The fibers of the outer layers of plywood should go along the hull of the boat, so it will be much stronger in operation and will not burst when trimmed.

Putty and paint

Для большей прочности и исключения протекания the boat needs to be covered with a cloth. To do this, the cover is sewn, which will cover it to the sides. After this, false begs are made to be installed on the outside of the bottom of the vessel. Holes are drilled in the frames of false bells for their further fastening.

After that make putty for the boat.They take the lime sifted through a sieve, pour the resin into it, mix it thoroughly, until it reminds the consistency of the batter. Then make a spatula and putty the entire hull of the boat.

Next, the body to the sides twice covered hotpitch. On the raw coating they put on a previously prepared fabric cover. It must be carefully compressed for tight gluing. All folds are well laid out. After the prepared false beats are nailed and the already fully assembled boat is covered with resin in three layers on top. Then it is turned over with a keel downward, sawn off all unnecessary gaps and removed the auxiliary parts, covered with two layers of drying oil with a gap of 35 hours. And then painted and decorated as desired, like other homemade boats, photos of which can be seen in magazines or in this article.

Ship Registration

Registration of homemade boats producedappeal to gims. There you should write a statement stating the type of the planned vessel, passport details, place of residence and telephone. You also need to attach drawings of the vessel from all projections, specify all the places where the mechanical parts will be installed, in general, all information relating to the product. In addition, you need to attach checks purchased materials for the construction of the boat. Only after consideration of the draft by the commission, it will be decided to register your home-made floating craft.