To change the flow of transported media to a complete stop, valves are used. The water tap is characterized by the following properties:

- simplicity of design and operation;

- use at high pressure drops;

- small size and weight;

- possibility of installation on any part of the pipeline;

- a small stroke provides convenient maintenance.

Valve types

Shut-off and control valves are classified according to three criteria:

- body shape;

- type of locking part;

- installation method in the system.

The shape of the valve body are as follows:

- straight-through - the flow is blocked by the valve seat in the transverse direction;

- angular - the locking element moves towards the movement of the medium;

- mixing - to obtain the desired water temperature.

The locking element varies in design:

- Sharovy - through sphere in the direct-flow case.When combining the longitudinal axis of the hole and the housing, the flow is fully opened. Rotation in the perpendicular direction at 100% overlaps the flow of fluid. The valve serves only as a locking element, and it is not suitable for regulation. The use of the device is associated with its high reliability, fast flow shut-off and compactness. It practically does not break anything, because there are very few details.

- Valve - with constipation associated with a threaded rod, screwed into the mounting nut. The node is used to regulate the flow rate and to completely shut off the flow (in the lowest position).

- Needle - conical piston with regulation of fluid flow under high pressure (about 220 Bar).

Valve materials:

- ball: brass, stainless or structural steel;

- Valve: cast iron, brass.

New materials are also used formanufacturing valves. The polypropylene body makes the device durable and cheap at the same time. Fluoroplastic coatings can increase the resistance to corrosion and aggressive environment.

Difference between valve and tap

Water taps and faucets are different thoughthey are often identified. The latter is installed between the joints of two pipes, forming a line. The faucet includes a valve and a spout directly through which water flows out.

Device and operation of the valve

The most important working body of the valve issaddle with a spindle, manually moved spindle. The valve is a tap valve, the device of which is given below, contains threads in the housing and on the stem, which has the braking property. As a result, the valve disc tightly pressed against the seat, blocking the flow when the valve is closed. In the open state, the flow area remains unchanged when the flow of water.

Normally, no thread is made in the case becauseshe quickly wears out. For this purpose, the chassis nut is fastened to it, into which the spindle is screwed. Then, instead of a worn knot, you can install another one, but the case will remain. All parts are interchangeable on the water valve (GOST 12.2.063-81, GOST 5761-74).

The valve opens by turning the knob. In this case, the spindle moves progressively, freeing the passage for fluid. If the rotation is performed in the opposite direction, the valve will close.

The device is connected to the pipeline through the inlet and outlet. Among themselves, they can be distinguished by the presence of an arrow indicating the direction of flow.

Angle valves

For a perpendicular change in the direction of fluid transfer with overlap and adjustment capabilities, an angle valve is used (the drawing is below: a - straight; b - angular)

The perpendicular arrangement of the inlet and outlet nozzles determines the purpose of the valve for pipelines that change direction by 90about. The principle of its work is the same as that of the pass. The stroke is made coaxially with the inlet pipe.

The scope of application of angle valves:

- When pipes are supplied to the heating radiator whenit is blocked or regulated by the flow rate of the coolant valve (see photo below). High-temperature polypropylene models are more convenient and cheaper than brass when combined with plastic pipes.

- Prevent vibration and buildup of pipelines.

- Reduced fluid flow rate without high frequency noise.

- In fire water mains during operation in all positions.

- Simplify the installation of pipes by reducing the consumption of fittings.

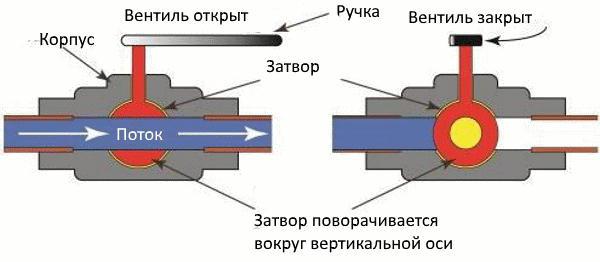

The device and principle of operation of the ball valve

The main working body of the valve is a ball withthrough hole. When the handle is positioned along the pipe, the tap is open. If it is rotated perpendicular to the pipe, it will close. The hole in the ball can be round, square, trapezoid or oval. In valves of small diameter, the valve is made floating, and for large-sized devices it is made on special supports. High tightness of the shutter is provided by an elastic seal. This allows you to install this type of model on gas pipelines.

The ball water valve works in two extreme positions when turning 90aboutwhen it is fully open or closed. Attempting to regulate the flow rate will lead to rapid deterioration of the seal.

Ball valves have more opportunities to connect pipes when installing water supply systems:

- checkpoints;

- angular;

- with three or more taps to redirect transported streams.

Pipe connections are made by choke, flanged and welded. The latter option allows you to permanently install a water valve in the system.

Shower Faucets

The device is performed by a single lever ball orform of two valve valves. The kit includes a removable shower head with attached flexible hose and a spout into the bath. The mixer perform hidden, bringing out only the water temperature control valves.

The classic option is the two-valveaccessory with manual adjustment of temperature. Cold and hot water are mixed in a special chamber, and then flow into the shower hose or onto the spout. The main elements of the device are two crane boxes with interchangeable gaskets.

A single-lever device with convenient water adjustment is becoming popular. The main element of the mixer is a replaceable cartridge. At failure, it is easily removed and replaced with a new one.

With built-in thermostat, adjustment is easier.It is pre-configured, which guarantees the exit of water at a given temperature. To do this, in the housing is a thermostatic element that distributes the flow. The only drawback of such models is the high price.

Installation

The valves of small diameter are installed onthread (up to 60 mm). The pipe has sgon, the joint is compacted with a hemp or fluoroplastic film. Winding is performed in the direction of twisting the thread. This creates a tight joint that can withstand high pressure.

Large diameter pipe flanged towasher straight or angle valve through the gasket. They are bolted together with nuts. The flange is connected to the pipe by means of arc welding.

Water valve: repair

If the valve is damagedreplace with the same unworn or new knot. To do this, the pipeline section is freed from the liquid, blocking it from both sides. Then, the valve-type locking element is removed. The ball valve is removed completely with open-end wrenches or adjustable wrenches. On the flanges, the nuts are twisted in parallel and gradually - 3-4 turns on each.

You should first check the healthseals that replace wear. Leaks mostly occur due to deformation of the gaskets and when the thread breaks down when improperly installed. Then the body and seat are inspected. In the absence of cracks, the knot is assembled again. The case is not subject to repair if mechanical damage appears on it. Adhesion to the pipeline requires it to be trimmed and the need for further welding work.

In this case, you will have to install a new or repaired water supply valve. An unprepared person should not undertake difficult repairs because of ignorance of his features.

Valves create additionalresistance, so blockages can form in the joints. It is not always necessary to remove the valves. Sometimes it is enough just to flush the pipelines, opening all the taps.

Replacement of the gland can be done carefully with their own hands. To do this, shut off the water supply from the riser, disassemble the locking mechanism, replace the gaskets and lubricate the moving parts.

Conclusion

Water valve is simpleoperation and does not require special maintenance. Each model should be used for its intended purpose. Simple repair of the valve can be done by hand, if you act carefully and correctly.