The planer is designed for processingblanks obtained after cutting wood. The equipment can be of different types. So, we distinguish jointing, quadrilateral and thicknesser machines. The first are designed for processing products "in the corner." Thickness planer is used to form parallel faces. There are units for processing metal products. In particular, a cross-planer is produced. This type of equipment occupies a leading place in its specific weight and value among metal-cutting machines.

Equipment designed for processing(direct or other specified), includes an electric motor, a ruler, a back plate of the working table, a handle of the level indicator of the front plate, a front plate of the working surface, a fan guard, a frame, a knife shaft, a starting device. A planer of this type consists of a frame, a pair of cast-iron plates. They form the desktop. The equipment also includes a drive, planing knives and a knife shaft.

The first plate (in the course of the material) is intendedfor the direction of the product before processing, the rear - in the process. The front is set lower by one and a half to two millimeters (that is, the thickness of the removed chip layer).

Each plate can be installed on the requiredheight. Adjustment of the height of the first is carried out by means of a handle, on which there are corresponding marks. The rear plate is installed using a screw with nuts.

The planer is equipped with a guide ruler. This part is removable. The ruler can be installed across the table, placed at the desired angle or flipped up.

The planer is also equipped with a braking device designed to quickly stop the cutter head after the engine is switched off.

The supply of material is usually producedmanually. Narrow products are processed in several pieces at the same time. In the process of working on the equipment with conveyor feed the product is sent end to end.

Modern automatic feeders can be used oncircular saws, planing, band saws, milling and grinding units. They provide a mechanized supply of material on equipment, which, as a rule, is produced with a manual mechanism for dispatching products for processing.

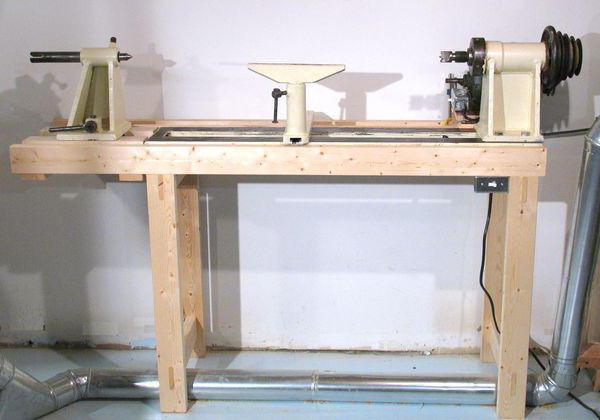

It should be noted that the planer with its own hands (yes, there are craftsmen who can create such a complicated equipment) looks much simpler than that produced in the factory.