If you want to buy a folding grill, thenYou can think about the possibility of its manufacture. Despite the fact that on sale today you can find similar designs of various sizes and shapes, such models are quite expensive. Whereas if you prefer cheap options, then, as practice shows, they serve a rather short time.

Preparation of materials

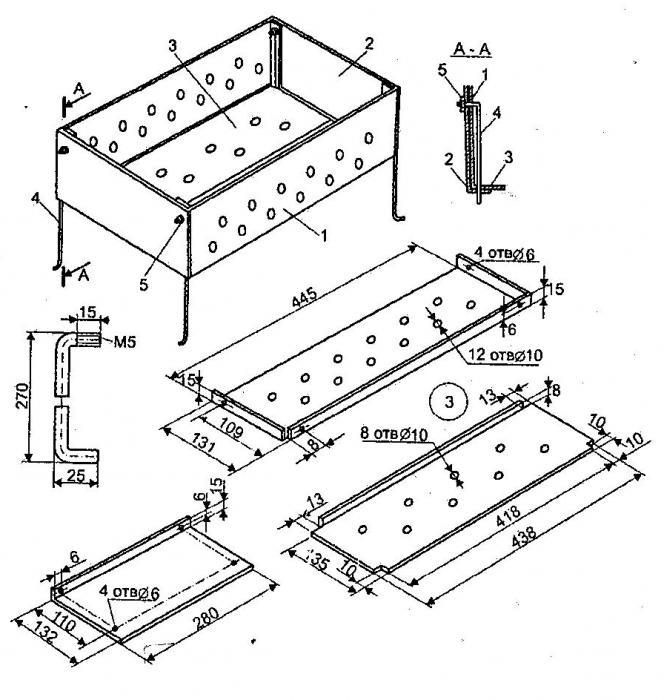

In order to make a folding grill, you needwill purchase sheet steel. The one that has a thickness of 2 millimeters, will go to the formation of the sides. Whereas 3 mm steel will be used for the bottom of the structure. Steel rods will be needed, the length of which should be equal to 20 millimeters. They will be used for the manufacture of legs. Get the nuts that will act as mounting for the legs. You will need and standard furniture hinges, with the help of them will be able to fix the sides to the bottom.

Preparation of tools

Folding grill can not be made withoutthe use of reinforced shears, designed to work on the metal. Useful Bulgarian, as well as roulette. The master will not do without a drill, square and ruler.

Sizing

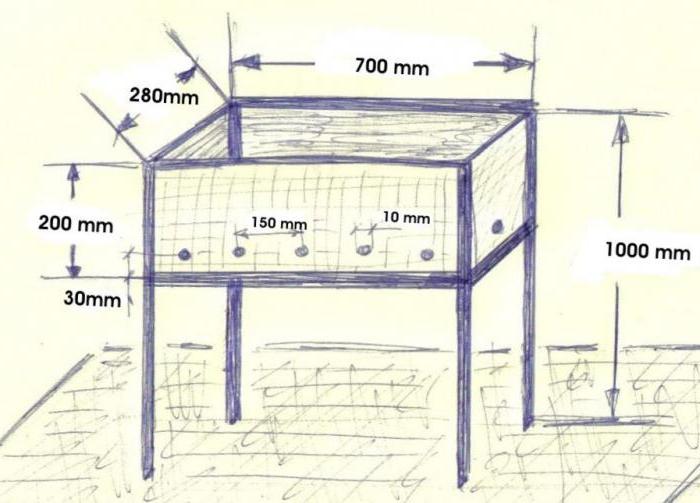

Of course, more impressive dimensions brazierwill allow you to cook a large amount of meat at a time, but it is worth considering the moment that this design will be folding. Therefore, it is best to choose sizes that allow you to conveniently transport the device in the trunk of a car. Experts do not recommend choosing too large case. Due to the fact that the standard length of the skewer is 70 cm, it’s still not worth making the grill too wide. The following are the most suitable dimensions: 50x30x15 cm. It is this kind of case that can be easily placed in the trunk for transportation.

The success of the work will be the selectionsuitable sheet steel. Unnecessarily thin walls and the bottom quickly burn out. Thick will contribute to the weighting of the structure, making it inconvenient to carry and transport. The most optimal option for the bottom is steel, the thickness of which should be equal to 3 millimeters.

Work on the hull

Если вы решили изготовить складной мангал, то After choosing the sizes, you can proceed to the practical part. It is important to do the body, its assembly involves at the first stage cutting sheet of tin, from which you should cut the workpiece with dimensions of 34x54 cm. The resulting element must be bent on the sides, departing 4 cm from the edges. This component will represent the bottom. Now you can cut two sides, the dimensions of which are 50x15 cm. While the other two side elements should be 30x15 cm. Long sides should be fixed to the previously curved part with the help of furniture hinges. Canopies can be welded or strengthened with screws. Now it is necessary to do short walls, in which cuts are made, and then the metal is bent. This will allow you to get fasteners for these sides.

Advice of a specialist

When a folding brazier is made with its ownwith your hands, you should prepare a rectangle with plywood or plastic, the dimensions of which should be slightly less than the bottom. This rectangle should be laid on the bottom of the barbecue, and then use it as a vane for air injection. The improvised fan prepared in this way will need to be transported along with the barbecue grill.

Manufacturing legs

Если изготавливается складной мангал своими hands, then at the next stage, you can do legs. From the thick rod should be cut 4 blanks. Their length will depend on how high a barbecue should be given. At one end of the bars should be cut the thread. The other end is sharpened. This will allow you to easily immerse the legs in the soil.

Barbecue folding should get the maximumconvenient to use, so it is important to take into account that if you do not make restrictions on the ends of the legs, they will go too deep into the ground. In order to exclude this moment, short longitudinal sections of rods should be welded on each leg. On the bottom of the case, the nuts should be welded to the outer corners. In them and the legs will be installed. On the long sides of the brazier you need to drill holes. They will contribute to uniform heating of the coal. In some cases, these holes are made in the bottom, while they are located closer to the edge. In order to ensure a comfortable carrying of the brazier, one can be welded to each side long wall.

Processing of the bottom and walls

When a folding brazier is made of metal,it is important to think about the durability of the structure. For this wall should be treated with paint that has heat-resistant characteristics. To perform this procedure yourself is quite simple. You can use the dye, which is used to process car mufflers. You can purchase such material in the auto parts store. Such a composition can undergo temperatures up to 800 degrees. In order to prolong the life of the metal, it should be missed. To do this, you will need to purchase a heat resistant black film. At the next stage, the brazier is disassembled, the heat-resistant film is peeled off, and the liquid sodium is dissolved in water. In this solution all elements are boiled for one and a half hours.

Conclusion

If the brazier is made foldinghands, the drawings can be prepared independently, using as an example the drawing presented in the article. This will allow you to carry out the work as correctly as possible, even if you choose other dimensions, based on your preferences. First of all, it is important to calculate the length of the legs, which will determine the height of the structure. In this case, be guided by the growth of the person who most often cooks meat with the help of a self-made barbecue.