Friction clutches are devices that are designed to transmit rotational motion in the mechanism. Quite often, elements of this type are found in the car.

They are also used in drives.The main advantage of modifications lies in their compactness. There are many types of couplings. To learn more about them, it is worth familiarizing yourself with the drawings of the model.

Model Device

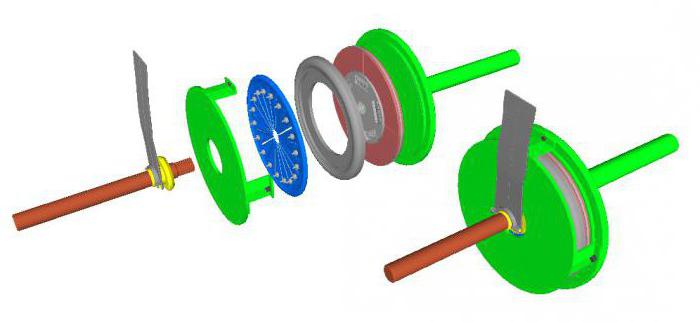

A conventional coupling includes a drum and a setdisks. The body is directly used in the cup shape. Many modifications are made with clamping plates. Their fingers are fixed at the base of the device. There is a plug for connecting the model. The torque of the gear is ensured by the bearings.

How does the coupling work?

The principle of operation of friction clutches is built ontransfer of rotational motion from the shaft. This process is due to the drum. It is tightly connected to the disks that control it. To hold the mechanism along the axis there is a spring. The standard model is fixed to the shaft through the plug. It is also worth noting that the speed of rotation depends on the bearing types.

Types of models

In the form of disc, conical andcylindrical modifications. A multi-disc model belongs to a separate category. There are devices with one or more drums. They differ in size, as well as the rotation coefficient.

Disk devices

The most common are diskfriction clutches. They use a big drum. At the same time, the clamping plate is fixed through the post. Many models use several screeds. Also worth noting that there are devices with fingers. They have a fairly high friction force. These devices can be found in machine tools.

Cone modifications

The cone clutch is friction (the drawing is shown below)suitable for drive units. It has several drums that connect through the plate. Forks are used in different sizes. It should also be noted that cone modifications are well suited for cars, often mounted on clutch mechanisms. The fingers in this case are attached at a slight angle of inclination. The driven plates are well ground and able to rotate at high speed.

Cylindrical devices

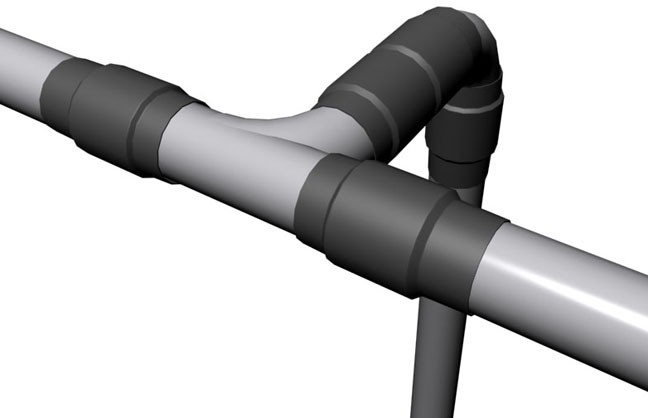

Cylindrical friction clutch veryrarely found in production. Most often, models are installed on cranes. The leading drums are of great width. In this case, the racks differ in size. Some experts point to the strength of springs. Couplings of this type are capable of withstanding large axle loads. They may have one or more bearings. Tightening fingers are installed in a large size.

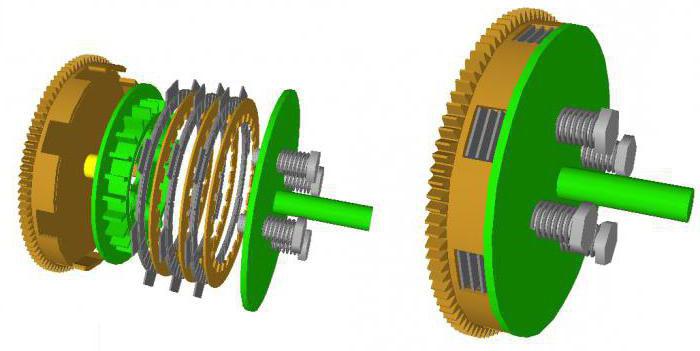

Features of multi-disk models

The multi-plate friction clutch includesa wide drum, as well as three working plates. Tightening pins are used on the pads. Many models have several supports. Also worth noting that there are modifications to the two springs. They have a high clamping force, large diameter forks are used. The most common devices are installed on the drives. Shells are of a cone shape.

Single-drum models

Friction clutches with one drum are made withone or more plates. The compression force in this case is regulated by the fingers. Some experts say that the modifications are suitable for cranes. However, they are still found in cars. It is also worth noting that the models withstand large overloads. The driven discs are polished, they can rotate quickly. Forks are most often installed at the bottom of the mechanism.

Models with several drums

Quite often in production there is a couplingsafety (friction) with several drums. Among the merits of the modification is worth noting the good stops and high downforce. Many models are capable of withstanding heavy loads. Mechanisms are rarely installed. It is also worth noting that the driving gears are of large size. Some couplings work from stretching fingers. They have two racks.

At the same time, the plug for connection is infront of the structure. Devices are not suitable for drives, because they have a slow start. It is also worth noting that there are models with a squeeze disk. The rod is in this case in a horizontal position. The fingers are small in size. In devices, high compression force. Drums can only rotate in one direction. The drive disk may be located behind or behind the squeeze plate.

Bushing models

The bushing friction clutches are suitable only formechanisms of adhesion. Some modifications are used in drive devices. Models can use several partitions. It is also worth noting that the tie fingers are installed above the release spring. The plates are in a horizontal position. The bushing is fixed between the partitions and plays the role of a shock absorber.

If we talk about the shortcomings, it is worth noting that the models have a small clamping force. Also models are not capable of supporting high shaft speeds. Devices are not suitable for drives.

Advantages of flange devices

The advantages of flange couplings lie in the fact thatthere is little wear and tear on the drum. The discs are usually fixed behind the counter. The partitions are of small size. Clamping plates are used to hold the stand. Springs are most often fixed at the bottom of the couplings. Some models work with drives. The connection to the shaft is via the plug. It is also worth noting that there are modifications with wide pressing discs. They have cone cases, and they are very compact.

Hinge models

Couplings on hinges are able to work in drivedevices of different power. Modifications are distinguished by wide partitions and short fingers. The discs are fixed at the base of the plate. Shells are produced in different sizes. Tie fingers are located in front of the rack. Partitions can be sliced. It is also worth noting that the force of the torque depends on the size of the drum. As a rule, he has a wide wall. At the same time, the edges are sharpened and do not rub against the disks. This was achieved through the installation of hinges.

Cam devices

Friction clutch with cams suitable formachine tools. Many models can withstand a significant load, but in this case a lot depends on the drum. In some devices, it is fixed between partitions. It should also be noted that there are models on the plates. A conical body is used to hold the parts.

The most common are clutches onsqueeze disks. They use small width drums. The rods in this case are connected with plugs. Many models are used in clutch mechanisms. Coupling fingers can be fixed at the base of the partitions. The driven drum is practically not erased. Coupling fingers are standardly used small.

Drive Models

Friction clutch for drives can work withone or more reels. In this case, the rods are made under small shafts. Drums are installed in a horizontal position. Many modifications are equipped with aluminum alloy wheels. It is also worth noting that there are modifications with spring devices.

If we consider the standard modification, thenIt has two squeezing discs. There is only one plate between them. The sleeve in this case is attached to the stem. In order to preserve the drum bearings are installed. If we consider models for large drives, then they have a squeezing disc with a partition. The driven drum works on a wide stand. Pressure springs can be with couplers. Couplings forks are fixed at the base. Some models are made with conical housings. In addition, compact working plates are used for couplings.