In any mechanism, for actuation of which the shafts are involved, a connecting part is necessarily present and is called a gear coupling.

Если есть два вала, которые нужно соединить по one axis or tilted to each other, it is best to transfer the load and effort to a semi-rigid connection using a gear coupling. A single gear coupling is placed under the condition that only angular displacement is allowed between the shafts. If it becomes necessary to compensate for radial or axial displacement, then put two single couplings. Gear coupling has a high reliability and good bearing capacity, because it is equipped with a large number of teeth. Such couplings work well in mechanisms with high rotational speed (cranes, conveyor equipment).

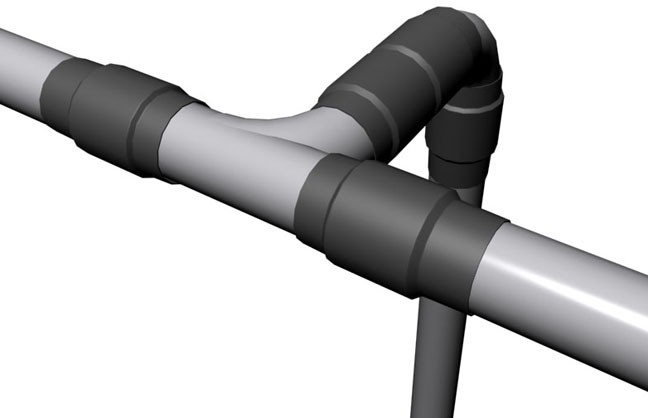

Couplings successfully compensate for radial, angular andaxial displacement of the shafts, due to the presence of side gaps in the mesh and on the teeth of the bushings of the sphere. All parts of which the coupling consists of, are made of steel: for a shaft with a diameter up to 140 mm - forged, and for large diameters - cast. To improve the wear resistance of the teeth, they are heat treated, and a viscous oil is introduced into the sleeve.

In principle, the functionally gear coupling has much in common with the cardan transmission, although it provides compensation for smaller angular displacements, but it has a large torque per unit volume.

Features of gear couplings

The gear coupling consists of two coupling halves,bolted, and two sleeves inserted into the drum clips. Between themselves, they are hooked with spherical teeth. Such couplings are standardized according to GOST 5006-55 for shafts with diameters from 40 to 560 mm. There are also other standards for gear couplings, which are used for unification in all CIS countries, depending on the torque, for example, GOST R 50895-96 (Russia), DSTU 2742-94 (Ukraine).

The wide scope of application and the various requirements that are imposed on the couplings have led to the fact that today, according to design features, couplings are divided into several classification groups.

So, according to the principle of operation, the couplings are divided into permanent, coupling and self-driving, and according to the nature of the work - into rigid and elastic.

On execution there are couplings with a detachable yoke (gear coupling GOST 5006-55-MZ), with a one-piece yoke and with an intermediate shaft (GOST 5006-55 - MW).

For the short ends of the shaft make the sleeve for the coupling according to GOST 12080 with cylindrical holes, and according to GOST 12081 - with tapered.

Also gear couplings can be made in accordance with the customer's specifications. If the customer needs an exclusive gear coupling, the drawing must accurately display all the necessary parameters.

When mounting the couplings, it is necessary to observe some features, in particular, mounting on the shaft should be carried out with a slight heat.

Recently actively begin to usegear couplings from polymeric compounds (capron, caprolon). Increased elasticity and the ability to more evenly distribute the load on the teeth, puts them in one row with the metal. In addition, polymer couplings have higher electrifying properties and gain in price.