Wire EDM machineserves for accurate execution of holes in metals of different density. The movement of the tool occurs with high precision and smoothness. The engines for it are produced at the enterprise - the manufacturer of machine tools - using a unique technology.

Design

Wire EDM machineequipped with plane-parallel engines. To do this, manufacturers create their neodymium magnets (NdFeB - neodymium-iron-boron). In addition to them, a unique K-SMS control system was required.

Classic EDMwire-cut machine is able to process only electrically conductive blanks. Metals arc burned to a considerable depth. In place of the cut remains a smooth surface, often not requiring additional processing.

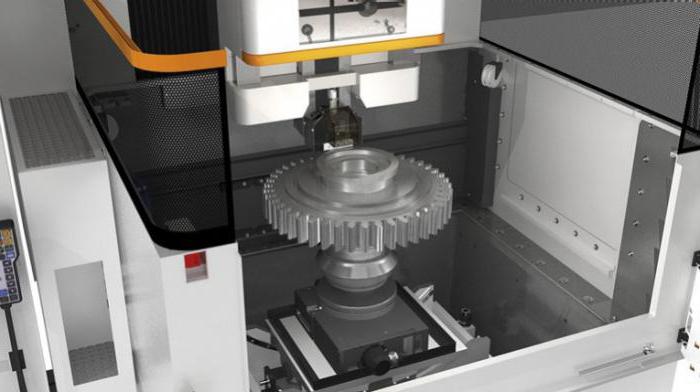

Wire EDM machineIt helps to obtain complex products: molds, strains, conical and cylindrical surfaces, protrusions and bevels. On sale you can find two-coordinate assemblies used for simple operations. More complex products are obtained with the use of five-axis machines.

Principle of operation

In the process of applying a wire-cut machineBrass wire is used most often as a cutting tool. It will be executed using a unique technology, and the speed and accuracy of processing depends on its quality.

If a high-power high-frequency impulse generator built into the machine described is used, the brass wire is equipped with a special coating. Its structure has several layers:

- Base - CuZn40 (copper-zinc alloy) or brass. Molybdenum, copper can also be used.

- Thermal diffusion layer - zinc concentration more than 50%.

- The top layer is pure zinc.

Due to this structure, the wire has several advantages:

- Withstands high temperatures.

- The arc in the process of processing is stable, eliminating the formation of nodules at the site of the cut.

- Reduced wire consumption for the length of the cut.

Wire EDM machines with CNCused mainly in mass production. Single products do not justify the purchase of expensive equipment, but some details can only be obtained by this type of cut. The zinc coating ensures the continuity of the automatic process by eliminating the shedding of brass from high-frequency currents.

Processing process

Electrical discharge machining basedon the formation of a spark due to the transmission of high frequency current through the minimum air or water gap. This process is most active with the participation of brass.

There are several types of metal processing on the above equipment:

- Copy firmware technology.

- Profile cutouts.

- Stitching.

More often wire for EDM machinesmounted on the movable node. The workpiece is placed on a fixed table. The cutting process is controlled by the CNC controller, which simultaneously controls several axes.

The essence of technology

Electrical discharge between wire andbillet leads to the removal of part of the metal. Selected particles are displayed in the volume of the working fluid. The sludge (crystallizing particles) is filtered and removed at the end of the cut. Processing speed is regulated by amperage. But the optimal modes should be selected, in which there are no nodules during the cutting process.

Electric erosion helps to make products with verythin walls, to process soft metals without mechanical damage. This method of cutting is used for flashing to a greater depth. The thickness of the wire is minimal, only this parameter is limited by the diameter of the obtained holes.

Дополнительной обработки не требуется, так как after cutting with current pulses no burrs remain. It also does not require expensive tools used in the classical methods of milling. This becomes true for blanks of viscous materials.

Equipment parameters

CNC process control extends the possibilities of electro-erosion treatment of metals. Deviations perpendicularity and straightness of movement of the axes are not more than 0.01 microns.

Mechanical accuracy is claimed by manufacturers, andno need to make additional adjustments. The machine is fully ready for the start of the automatic cycle; you just need to load the part model in the standard code.

Modern electronics provides precisiondisplacement due to angular and linear sensors whose resolution is 1.5 microns. The accuracy of the contours obtained varies from ± 1.5 to ± 5 μm over a length of 300 mm.

Characteristics are selected individually for the needs of production. Based on this, the cost of equipment is formed, focused on a suitable model.

Additional options

The buyer of an electroerosized machine can retrofit equipment with the options presented:

- The controlled position of the C axis. Often required for milling cylindrical billets.

- Turret head with additional degrees of freedom tool. Using such a model, geometrically complex parts are obtained.

- The table may have additional axes. Such option is used when processing case products or several preparations for one cycle.

В стандартную комплектацию включают системы cleaning of the working fluid, allowing filtration with quality up to 3 microns. Dirty cartridges are standard sizes and change fairly quickly.