When constructing heating mains, main pipes,hot water flows into special protective trays made of reinforced concrete. The pipeline system may be located above or above the ground, but in each of these cases the components must be reliably protected from the effects of low temperatures and moisture. For this purpose, special trays and ducts are used along which the pipes of the heating main pass.

Sizes of reinforced concrete trays

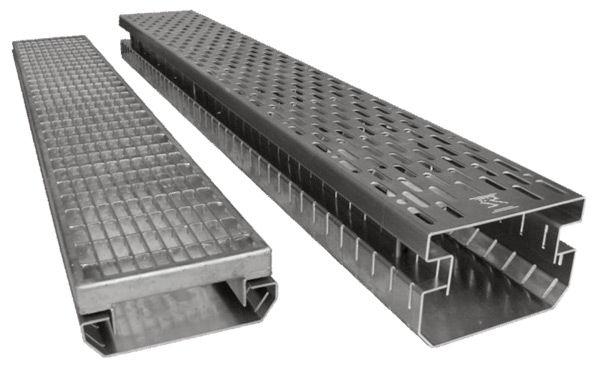

Tray for the heating of reinforced concrete hasrectangular shape and has a gutter configuration. The parameters for the type of width, length and height of different models differ among themselves, but these values are spelled out in GOST. Structures are made of heavy concretes, which, after solidification, are extremely resistant to loads of different types. In addition, these trays are very frost resistant.

If you use low-quality concrete, then it will crack and burst in the cold, so when choosing trays, you should ask what technology was used to make structures:

- ordinary pressing;

- vibrating casting;

- ordinary casting;

- vibropressing.

Tray for the heating route will be the mostquality, if carried out by the method of vibration technology. The most important parameters when installing heating mains in trays are the quality of the material and dimensions. Depending on where the communications will take place, certain requirements are placed on the trays.

Among others, it is necessary to highlight the correspondencesizes of gutters with pipes. For example, metal pipes should not be flush with the concrete walls of boxes. This requirement is especially relevant if the pipes are additionally wrapped with insulating material. Therefore, the tray for the heating main is selected in several large sizes as compared with the external diameter of the pipeline system.

Today there are certainstandards for trays dimensions. For example, the length can vary from 720 to 2970 mm, with regard to the width, it varies from 570 to 2460 mm. The height of the gutter is limited as well as the wall thickness. In the first case, the value can be in the range from 530 to 740 mm, while in the second - from 40 to 80 mm. The inner surface of the tray is also important when choosing, it can vary from 450 to 2180 mm, whereas the height of the channel of the inner surface can be equivalent to the limit from 300 to 1200 mm. Weigh trays from 100 to 3000 kg.

Steel for trays

Tray for the heating main should be made using high strength steel. Usually steel is used for this, belonging to the following classes:

- AI

- A-III.

- Bp-i.

It is used in the first stage to formmetal frame, which is covered with high or medium density concrete. This allows you to get reinforced concrete structures with different parameters for laying in the ground.

GOST reinforced concrete trays

Reinforced concrete trays for heating mains, sizeswhich were mentioned above, must be manufactured in accordance with state standards 23009-78. Concrete must be made of Portland cement grade M-400 or higher, in addition, sulfate-resistant portland cement should be used. For concrete mixes, too, there are strict requirements, which are spelled out in GOST 26633-91.

Purpose of trays

Reinforced concrete trays for heating mains are usedto protect pipes from damage and rodents, to save heat, to protect against flood and groundwater, as well as to protect against chemicals in places of their accumulation and availability. Such trays are necessary so that the pipes do not interact with the air, which prolongs their service life.

Trays for the heating main, the size of which is GOSTmentioned in the article, can be used even in seismically hazardous zones. When the gutters are covered with lids, it allows to exclude unforeseen situations. The constructions are quite simple, so in a short time they can be opened to eliminate possible system breaks.

Used with floor slab trays

Concrete tray for heating must beused in tandem with floor slab. It is located on top of the gutter, and it is required that foreign elements do not fall inside when filling the ground. Otherwise, the meaning of the idea is lost, because the pipeline system should not be subjected to additional loads.

The overlaps are rectangular andbe made of reinforced concrete or concrete. These products must be sized to fit concrete trays. The concrete tray for the heating main is covered with a slab, which is made of concrete of the same brand as the complaints. This allows you to maintain the integrity of the structure of the box, which will be ready to serve for several decades. With the increase in the thickness and size of the plate, its price rises, since more raw materials have to be spent on manufacturing.

Classification trays according to the method of laying

Tray for heating, dimensions of which are mentionedin the article may differ in the way of laying. Each variety has its own label. For example, if the gutter is indicated by two letters - KL, it means that there is a channel in front of you with ceilings resting on them. If the designation looks like this - KLP, then you have channels from the covers with supported trays.

There is also the designation CLS, whichindicates that the channels in front of you are from trays leaning on each other and connected by channels. Such channels are suitable for moving inside a person, whose height does not exceed 180 cm. Interestingly, only a few firms are engaged in manufacturing such trays in Russia. Before installation, a sand cushion is placed in the ditch, which is necessary for a firm and direct contact of the gutter with the ground. When the tray for the heating main is laid, the dimensions of which are mentioned in the article, it is important to use protective rubber seals, which should be between the covers and the complaints. Subsequently, the seams are poured with concrete, which allows you to create a monolithic system.

Decoding of the marking

Reinforced concrete trays for heating mains, the dimensions of which should be selected with regard to the pipes used, are marked according to GOST 13015-83. The inscriptions on the products should contain information about:

- manufacturing company;

- product weight;

- date of manufacture;

- brand;

- sizes;

- strength;

- stamp of technical control.

Decipher marking is quite simple.Reinforced concrete gutters are marked with the letter "L". Then you can find a typical size. Through the hyphen manufacturer specifies the maximum load. According to the rules of GOST, the product length may differ from the typical one, in this case one more figure can be seen in the marking after the main parameters.

Conclusion

For the reason that the reinforced concrete traysundergo a high load and are used in important areas, their production is regulated by state standards. They can find the quality of the used concrete, as well as the conditions of operation and installation. If the trays do not correspond to at least one of the points shown, then the products cannot be considered as high-quality, that is why it is unacceptable to use them in construction.