Pure iron is characterized by limitedlist of properties and as the main metal is not of great interest. But alloys based on it have enormous potential, you only need to determine the chemical composition and make the correct heat treatment.

The most common structural steel

All iron-based steels are black.metallurgy and have numerous classification. It is produced according to various parameters: chemical composition, purpose, content of harmful elements, strength and toughness, flexibility, and many others. Constructional - became the most common in the application. Some of them have universal properties and interchangeability.

Structural steel 20 refers tomedium carbon class, has a ferritic-pearlitic structure. Quality steel, i.e. it has a reduced content of harmful elements: sulfur and phosphorus. No restrictions on weldability. The optimal combination of strength and ductility makes it just a versatile material for the production of rolled steel, parts subjected to subsequent thermomechanical and thermochemical processing (cementing, zinc plating and chrome plating).

Twenty has found its application

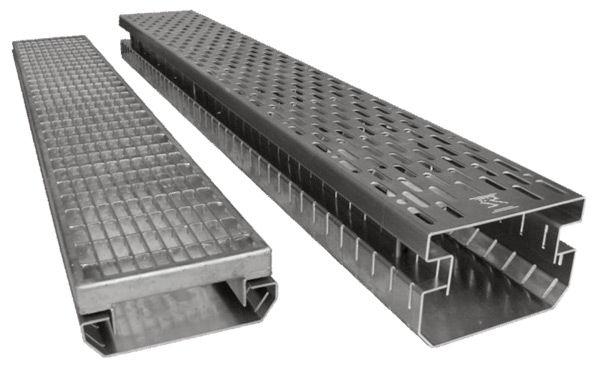

Steel 20, whose properties may vary inlarge limits using chemical-thermal, thermomechanical processing, most in demand in pipe production in the manufacture of parts with a hard surface and a soft middle. These can be shafts, sprockets, gears, bolts, crane hooks, fittings, stamping sheets, decking, nuts and bolts for non-responsible fastening. Manufactured pipes of this steel grade are used to transfer gases, steam, non-corrosive liquids supplied under pressure. These are pipes of superheaters, pipelines, high-pressure boilers and manifolds.

Structure change by thermochemical treatment

The same brand can change itscharacteristics using heat treatment. Steel grade 20 has good plastic characteristics, so products made from it are obtained by several methods: casting, cold or hot rolling or drawing. After receiving the parts by the method of castings, chemical-thermal treatment can be applied to them. The purpose of this procedure is to obtain a hard, wear-resistant layer that does not give in to corrosion, and a soft plastic middle.

For this, the finished part is placed inthe corresponding medium (lined with dry carbon-containing substance, placed in a gaseous or liquid medium), after which it is maintained from several hours to 1.5 days at a high temperature. Machining of parts by this point should be completed, since after thermochemical processing the product will have the final structure. The element saturates the top layer of the product (from 0.3 to 3.0 mm), accordingly improving its structure and properties.

Depending on the substance used processingcalled: cyanidation (zinc plating), carburizing (carbon), chrome plating (chromium). Carbon gives strength, zinc - corrosion resistance, chromium, in addition to all listed, makes the surface mirror.

Structure change by machining

Unlike the previous processing method,which is carried out solely to impart hardness in the upper layer of metal and flexibility in the internal, thermomechanical processing is one of the methods of shaping. Steel 20 can be deformed in both hot and cold ways. Each form has its advantages and disadvantages. But they are used on the basis of the most necessary properties.

Hot deformation is applied to productshaving a wall thickness of more than 5 mm. Since doping and a decarburized microlayer (an undesirable structure) is formed when the metal is heated, it is impractical to use this type of rolling for thin-walled parts. However, it has one great advantage over cold deformation.

Холодное деформирование применяется к деталям, having a thickness of less than 5 mm. For cold drawing, only “soft” types of steel are suitable. During rolling, the metal undergoes significant deformation, or cold working. This leads to an increase in its strength and the presence of large stresses in the structure. Such a metal cannot be heated due to its thin walls (to take a leave, that is, to restore the old structure). It is more susceptible to damage during impacts and other dynamic loads. Structural steel pipe (steel 20) is distinguished by the methods of manufacture and the resulting technical characteristics that affect the application. For the production of each type of pipe has its own standards, standards, equipment.

Cold rolled pipes with straight seam

The production process begins with the preparationsteel strip. For this, sheets of steel are cut into strips and welded into one long strip. The tape is fed to the bending rolls, where it takes the form of a pipe. The next stage is welding. For any design, this is the weakest point. It is completely impossible to eliminate the disadvantages that occur during welding (the appearance of oxides and carbon burnout), but using some techniques, they can be reduced. In order to connect steel 20, electric arc welding in a protective atmosphere of inert gas (argon) or induction welding (high-frequency currents) is used. The pipe passes the obligatory inspection of the weld, after which it is cut into parts of the required length and stored.

Spiral seam cold drawn pipes

Подготовка стали для производства этого вида pipes repeats the same process as for pipes with a straight seam view. Also identical: welding, control and trimming. Only the folding angle of the tape differs, at which the subsequent seam rounds the pipe along a spiral curve. By virtue of its design features, this method is the most durable. And withstands greater tensile loads than these products with a straight seam.

Seamless tubes

Seamless pipes are particularly durable, possessseveral advantages: they do not have welded (weak points), there are no stresses in the steel structure, the thickness of the pipes is at least 5 mm. Their production is a more complicated process, and therefore expensive. Steel 20 is unique in that pipes can be manufactured in two ways - by cold and hot drawing.

Hot rolled seamless

After warming up over 1100ºС billetstitched sleeve and forms an internal diameter. With further drawing, the pipe takes the specified dimensions of the inner, outer diameter and wall thickness. During the whole process, the temperature of the rolled stock remains high. And only after the adoption of the final form of the tube is cooled. During long-term cooling, tempering occurs, all the negative effects of rolling, increased strength and brittleness are removed. With full cooling, steel gains 20 characteristics that were originally present. This technological process involves the manufacture of pipes with walls of at least 5 mm, and the maximum thickness can reach 75 mm.

Cold drawn seamless

Unlike the previous method, in thisobserved a small temperature nuance. The workpiece is heated, but after the initial flashing with a sleeve, the temperature is not maintained, and the workpiece is drawn out in a cold state. This method differs from hot-rolled one in that it is possible to manufacture strong pipes with thin walls, whereas in the hot-rolled method only thick walls are provided. For the final structure, these two methods are identical, since after cold rolling the pipes undergo normalization, at which the structure is partially restored, and the stresses disappear.

This is not the whole list of products, which are based on steel 20 GOST 1050-74. The needs of the population are increasing, new ideas and production are emerging. But this brand only changes its form and purpose, reserving the right to exist.