Metallurgical industry is one of the most importanteach country’s GDP, it also produces unique and useful materials. Without the production of steel mills, mankind could not do. Steel is one of them. There are different types of this material that are used in many industries. Steel, which has a high ductility and wear degree, it is also Hadfield steel, is a unique alloy. Requirements for it are governed by GOST 977-88 and foreign analogues (USA, England, Germany, China, Japan, Finland, Spain, Korea).

The history of Hadfield steel

Based on the name, it can be argued thatRobert Gadfield got this fusion. Who was this developer? Robert Hadfield - English metallurgist, who received an alloy with increased strength in 1882. Quite quickly, this steel became widespread and proved to be a very unique material.

After Hadfield developed a uniquesteel, its development interested in the military. This is not surprising, since such an alloy is an integral component for the creation of protective equipment for the military.

Rugged Infantry Helmets - Firstprotective gear, which is based on Hadfield steel. Such helmets were used by soldiers of the British army, then the US military became interested in the development and began their production. Until the 80s, Hadfield steel technology has not changed. But from the 80s an organoplastic was developed, which was not inferior in strength to the material developed by the British metallurgist, but was much lighter.

Infantry helmets are not the only use.Hadfield steel. The British company Vikkers was the first to use this high-grade steel for other purposes. Tracked tank truck began to be produced from Hadfield alloy in the 20s. Steel increased the mileage of tank trucks from 500 to 4800 kilometers. During World War I, such an increase in mileage was considered almost a miracle. Steel Hadfield has become indispensable for tank building. Soon this alloy was used not only in tank construction, but also in other industries. In the USSR, Hadfield steel began to be melted in 1936.

Hadfield Steel: Composition

Chemical composition | |||||

Element (Table. Mendeleev) | Fe | FROM | Mn | Si | Other impurities |

Content% | 82 | 1 | 12 | 1 | 4 |

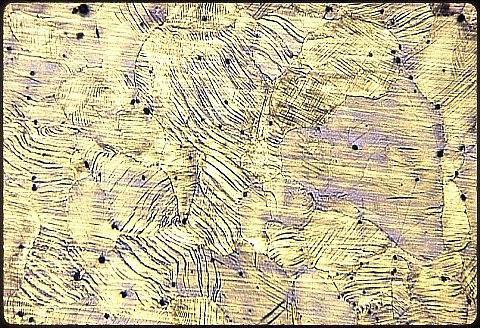

Analyzing the chemical composition, especiallypercentage of carbon and manganese, you can see that it is austenitic steel. This structure improves wear resistance and hardens the alloy. Thus, steel is resistant to deformation processes, possessing a high degree of ductility and toughness. Metallurgists claim that this alloy was the first alloyed steel, which began mass production.

Hadfield steel properties

Due to its properties, austenitic steel is notcould be processed with cutting tools, as it has a high viscosity. For the manufacture of products from this material can only be suitable casting.

Hadfield alloy has a high ability tohardening, which is significantly higher than that of similar steel alloys. Austenitic steel has low hardness, but also high wear resistance during impacts, high pressure and temperature drops. Based on these characteristics, we can say that the steel of the British metallurgist is suitable for working in aggressive environments.

Features of Hadfield steel welding technology

The thermal conductivity of austenite is significantly lower thanother steels, 4-6 times. The coefficient of thermal expansion is several times greater than that of low-carbon steels - 1.9 times. These are very important characteristics of the metal, as it affects the possibility of cold cracks in the area exposed to temperatures.

Существует значительная вероятность и горячих cracks, which is associated with casting shrinkage of the alloy, which is 1.6 times more than low-carbon metal. High temperature transforms the austenitic structure into martensitic, which increases the risk of cracks in the area of high temperatures.

Hadfield steel applications

Due to its chemical composition, characteristics and characteristics, austenite is used in many industries. Using steel products, you can be confident in their reliability and high strength.

Wear resistant steel is enoughpopular material. A huge number of industrial enterprises that produce high-strength products use Hadfield steel. The following products are made from this alloy:

- Engineering products.

- Truck tracks caterpillars.

- Tractors.

- Railway crosses.

- Switches that can work in hard shock loads and abrasion conditions.

- Prison bars on the windows.

- Crusher components.

Entertaining is the prisonaustenite gratings. Many believe that this is a uniform mockery of prisoners who are trying to escape. According to the classics of the genre, many relatives carry hacksaws for prisoners who, in the hope of freedom, begin to cut window grids.

In the case of using ordinary metalthere is a chance of escape. But Hadfield's alloy is a wear-resistant steel that cannot be cut with a regular hacksaw. If you start to cut Hadfield alloy gratings, then the surface is hardened, which entails hardening of austenite. The hacksaw increases the hardness of the grille to the hardness of the hacksaw and higher. Therefore, we can talk about the unreality of escape.

Steel 110G13L

Chemical composition | |||||||

Element (Table. Mendeleev) | Neither | FROM | Mn | Si | FROM | P | Wed |

Content% | Max. one | 0,9-1,5 | 11,5-15 | 0,3-1 | Max. 0.05 | Max. 0.12 | Max. one |

Steel grade 110G13L - alloyed, which is used for castings and has special properties. This steel has a high wear resistance when shocks or pressure drops.

Application of steel grade 110G13L

This steel grade is used in the production of the following materials:

- Heavy duty parts that must be durable.

- Cone crusher.

- Teeth, walls of excavators.

- The body of the ball, vortex mills.

Steel Grade Analogs

Many countries produce similar steel.

England | France | Austria | Czech Republic | China | Italy | Spain | USA | Germany |

Bw10 | Z120M12M Z120M12 | BOHLERK700 | 422920 17618 | ZGMn13-1 | GX120Mn12 | AM-X-120Mn12 | A128 J91129 | 1.3401 X120Mn12 GX120Mn12 |

Properties of steel grade 110G13L

Technological and mechanical properties of the material are given in the tables.

Foundry properties | |

Foundry shrinkage,% | 2,6-2,7 |

Technological properties | |

Welding | Not used for making welded structures. |

Holiday fragility | No addiction |

Flock sensitivity | No sensitivity |

Mechanical properties at T = 20aboutFrom steel grade 110G13L

Assortment | The size | For example | fromat | fromT | d5 | and | KCU | Heat treatment |

- | mm | - | MPa | MPa | % | % | kJ / m2 | - |

Castings, GOST 21357-87 | 800 | 400 | 25 | 35 | Hardening 1050 - 1100 ° C, cooling occurs in water | |||

GOST 977-88 | Fur. properties are set according to customer requirements | |||||||

Heat treatment

Heat treatment of Hadfield steel directlydepends on the carbon content of the alloy. The higher the carbon level, the higher the temperature should be. For example, if in the alloy it is at the level of 1%, then the temperature should be not lower than 900 degrees. If carbon is 1.5%, then processing is possible at 1000 degrees. If carbon is 1.6% in the alloy, the temperature should be above 1050 degrees. This is followed by cooling with water.

High temperature is necessary for completedissolving carbides, deteriorating the quality of the casting, and for the growth of austenitic grains. The dwell time of the casting depends on its thickness. Thus, a thickness of 30 millimeters requires an exposure at 4 hours, and at 125 millimeters - at 24 hours.

Wear resistance of Hadfield steel in castThe condition is the same as after quenching. The structure of austenite is surrounded by a carbide mesh and behaves in conditions of wear in the same way as a uniform hardened alloy. That is why it can be argued that cast austenite in some microvolumes has the same viscosity and wear resistance as hardened steel. Its increased brittleness is due to the influence of the carbide mesh, which causes a strong concentration of internal stresses.

Hadfield steel has been developed severaldecades ago. Today, alloy steel is an integral part of the production of many products in different industries. Without it, industries such as engineering, oil and gas, chemical, food, energy industries could not function normally. Do not forget about the construction, tank building and development of new types of weapons that use the new achievements of the metallurgical industry. However, engineers and metallurgists do not fully understand all the properties, features and characteristics of alloyed steels.