Сыпучие или кусковые базовые строительные materials in accordance with technical standards vary in size. When sorting materials by sieving through the sieve system, the fraction is determined. This means that crushed stone or sand is divided according to the size of the particles or grains.

What fractions are rubble?

Самым распространенным материалом на любом construction is crushed stone. It is used for the device of road pillows, blind area, it is part of the concrete mix. In each case, use a certain size of rubble with its inherent physical characteristics. GOST stipulates that a fraction is the size of a physical unit of a stone that fits into the established framework. There are two main standard fractions (5-25 mm and 25-60 mm), which are used in construction. Modern equipment allows cutting out crushed stone in narrower values that are required for the implementation of individual tasks - from the smallest (up to 1 centimeter) to very large (from 12 to 30 centimeters).

What is crushed stone for?

Industrial production of concrete and reinforced concretestructures, as well as asphalt, provides for the use of a fine fraction of crushed stone - from 5 to 20 mm. When constructing tram tracks, railway embankments, road pads, larger rubble is often used (fractions 20/65 or 40/70 mm).

Large fractions are suitable for the construction of foundations, and in landscape works they use the largest stone - up to 30 cm.

Thus, the fraction is the size of crushed stone that has been selected, prepared and tested in accordance with the requirements of GOST.

A common indicator for all fractions of the stone is considered to be the cuboid shape of particles, which is achieved in the process of crushing.

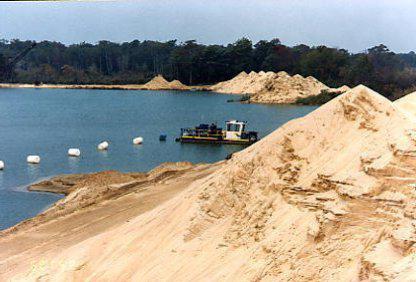

Sand Fractions and Scope

Sand is used not only in construction, butalso in industry, for example, for the manufacture of heaters or glass, the production of adhesive and dry mixes, putties, self-leveling floors, casting molds, in sandblasting works. To avoid problems with the choice of raw materials, you need to know its characteristics and purchase exactly the sand that is needed for a particular type of work.

Classify sand according toorigin and processing method. It can be river, marine, quarry, quartz, perlite, and for each species there is its own regulatory document. For example, the GOST standards governing the parameters of the raw materials used in cement testing distinguish between polyfractional and monofractional quartz sand. Reference is considered to be sand from deposits of the Czech Cretaceous region.

A common characteristic for different sandsorigin is the size of the module (fraction) - this is when the majority of particles of approximately the same size. So, sand is very large, consisting of grains up to 0.5 cm in diameter. Large - 2.5-3.5 mm, medium - 1-2.5 mm, small - from 0.5 to 1.5 millimeters, and smaller grains of sand fall into the category of “fine sand”.

Речной песок – идеальное сырье для производства concrete products, and quarry products - for mixing masonry or plaster solutions, foundation works. Quartz sand is mainly used for the production of tiles and plastic products, earthenware and porcelain, for filtering water, welding materials and molds.