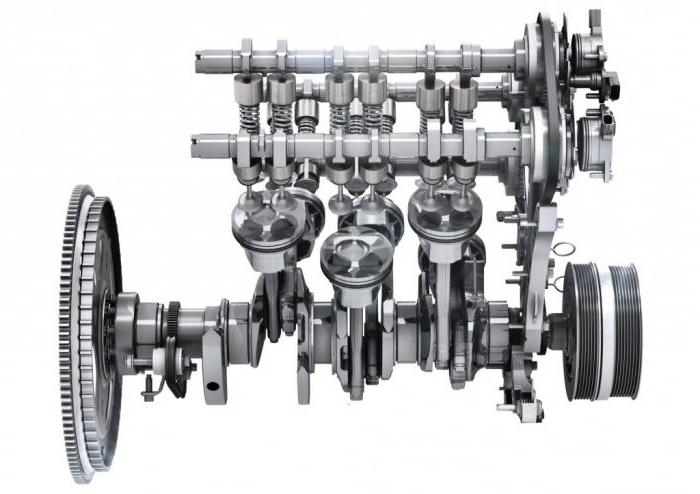

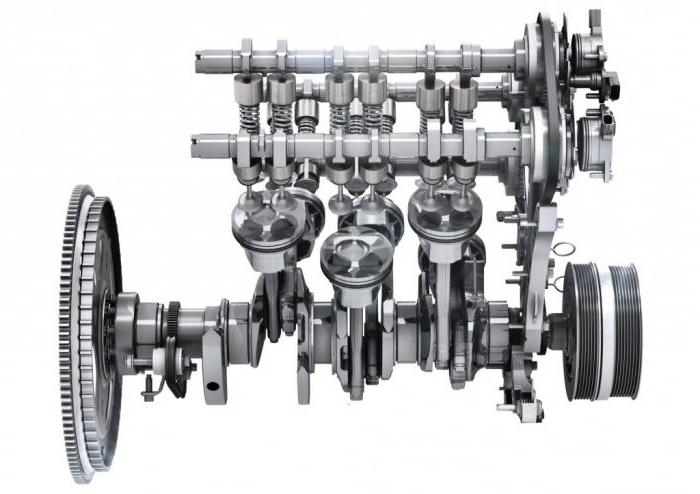

The crankshaft is one of the main elements of the engine. It is part of the crank mechanism. She has a complicated device. What is this mechanism? Let's consider.

Device and purpose

The crankshaft senses forces from the piston andconverts them into mechanical energy. This mechanism is influenced by rotational forces. He works constantly under high load. Therefore, in order to prevent the part from failing prematurely, crankshafts are made of high-quality, high-strength cast iron alloys. Then all parts are quenched with high frequency current. There are shafts with a double counterweight or even without a counterweight. The engine kneleval is located directly in the motor housing. As for the design, it generally depends on the engine.

Despite some differences in designsThere is a lot in common. The crankshaft is a complex of several parts. As a support for this design, radical necks are used - more often there are models with four necks, but there are also three-bearing ones. In the six-cylinder engines installed shafts, where such supports 7. In order for the crankshaft to be balanced, use counterweights. If the cylinders have a small diameter, then use single counterweights. At the expense of these parts ensures the smoothest operation of the power unit.

Auxiliary mechanisms

So, knowing what the crankshaft is forengine and what forces affect it during operation, you can understand why the mates between the cheeks and the connecting rod necks are slightly rounded. This helps prevent premature destruction.

Between the cheeks there is a connecting rod rail.Engineers who service engines call it a "knee." It is designed to ensure uniform ignition, so that engine operation is as balanced as possible, so that minimum torsional and bending forces act on the shaft. The crankshaft is a part that operates at high revs. The rotation of the connecting rods and the shaft itself on the supports is provided by sliding bearings. Installed thrust elements at the extreme or middle root neck. The purpose of this bearing is to prevent axial movement and movement of the mechanism.

If we consider how many parts must be coherently andclearly work in one mechanism, it is easy to say that in the production process the crankshaft is carefully balanced. But sometimes it is possible to detect and unbalanced parts. These products are not available for sale.

The work of the crankshaft from the inside

The principle of operation is generally simple.When the piston is as far removed as possible, the cheeks and the crankshaft connecting rod line up in one line. At this point, the fuel in the combustion chambers is ignited and gases are released, which move the piston to the crankshaft. With the piston moves and the rod, the head of which rotates the crankshaft. When the latter unfolds, the crank neck moves upwards and the piston moves with it.

Lubrication system

Lubrication plays an important role. The crankshaft is a part of the rotation, which means it will experience friction.

From the common lubrication line to the neck supports, a lubricant supply is provided. Then, through the channels in the cheeks, the oil will fall to the necks of the connecting rods. Lubrication significantly increases the wear resistance of all shaft parts.

Malfunctions

В силу высоких нагрузок данный механизм выходит out of service. Among the typical faults can be identified accelerated wear of the necks. It is associated with problems in the cylinder block. Also often there are scuffs on the surfaces of the necks.

This happens due to unsatisfactorycirculation or lack of lubrication, or in connection with violation of temperature conditions. Scratches on the surfaces of the necks can be seen especially often. You just need to distinguish between scratches and cracks that are formed due to metal fatigue. Often there are beats and deflection details. This is especially true for high-speed car engines.

One more typical malfunction - a deviation of necksfrom their factory size. But this is a more natural process than all the others. It should be borne in mind that the dimensions of the crankshaft have a tolerance of no more than 0.02 millimeters. Any discrepancy is eliminated by groove on specialized equipment.

How to perform a replacement?

Of course, with some types of faults you cando repair - grinding or groove. But sometimes to restore the shaft fails. In this case, you can replace the old mechanism with a new one. By the way, in the engine is the most expensive component. Especially in diesel powertrains.

Before the crankshaft is replaced,axial play is checked. This will simplify the selection of axial liners. It is necessary to find labels on the insert and the cylinder block. They indicate the installation direction of the main bearing caps. All parts that prevent you from dismantling the shaft must also be removed. In the repair manuals, the dismantling process is described differently, as there are 8-and 16-valve engines, with in-line or V-shaped cylinder arrangement. Then you need to install a new crankshaft in place of the old one - you must strictly follow the instructions of the car manufacturer and not confuse the crankshaft position. In view of the high responsibility, all work must be done in a specialized service.

So, we figured out the device, purpose and principle of operation of the crankshaft of the car.