On the LM317T microassembly power supply circuit (PSU)simplified many times. Firstly, it is possible to make an adjustment. Secondly, the stabilization of the power produced. Moreover, in the opinion of many radio amateurs, this microassembly is several times greater than domestic analogues. In particular, its resource is very large; it cannot be compared with any other element.

Power supply base - transformer

Needs use asvoltage converter buck transformer. It can be taken from almost any household appliances - tape recorders, televisions, etc. You can also use transformers of the brand TVK-110, which were installed in the block scanner of black and white televisions. True, they have an output voltage of only 9 V, and the current is quite small. And if you need to power a powerful consumer, it is clearly not enough.

But if you want to make a powerful power supply, then it makes more sense.use power transformers. Their power should be at least 40 watts. In order to make the power supply for the DAC on the micro-assembly LM317T, you will need an output voltage of 3.5-5 V. It is this value that you need to maintain in the power supply circuit of the microcontroller. It is possible that the secondary winding will need to be slightly modified. The primary one is not rewound, only its isolation is carried out (if necessary).

Rectifier cascade

The rectifier unit is an assembly of semiconductor diodes. There is nothing difficult in it, only it is necessary to determine what type of straightening should be used. The rectifier circuit can be:

- half-wave;

- full-wave;

- pavement;

- with doubling, trebling, stress.

The latter is reasonable to apply, if, for example, onThe output of the transformer is 24 V, and you need to get 48 or 72. At the same time, the output current will inevitably decrease, this should be taken into account. For a simple power supply, the most suitable bridge rectifier circuit. The used LM317T micro assembly cannot be made powerful. The reason for this - the power of the microcircuit is only 2 watts. The bridge circuit allows you to get rid of the pulsations, and the efficiency of it is much higher (if compared with the half-wave scheme). It is allowed in the rectifier cascade to use both diode assemblies and individual elements.

Housing for power supply

More sensible materialuse plastic. It is convenient in processing, gives in to deformation when warming up. In other words, you can easily give the blanks any shape. And for drilling holes will not take much time. But you can work a little and make a beautiful, reliable body made of sheet aluminum. Of course, there will be more trouble with him, but the appearance will be amazing. After the body is made of sheet aluminum, it can be thoroughly cleaned, primed and put on several layers of paint and varnish.

In addition, you immediately kill two birds with one stone - getbeautiful body and provide additional cooling micro assembly. On the LM317T, the power supply is built on the principle that stabilization is carried out with the release of a large amount of heat. For example, you have 12 volts at the output of the rectifier, and the stabilization should produce 5 V. Here is the difference, 7 volts, goes to heat the microassembly body. Therefore, it needs high-quality cooling. And the aluminum case will contribute to this. However, you can do and more advanced - to mount on the radiator a thermal switch that will control the cooler.

Voltage stabilization circuit

So, you have an LM317T microassembly block diagrampower on it before my eyes, now we need to determine the purpose of its findings. There are only three of them - input (2), output (3) and mass (1). Turn the body to face it, numbering is from left to right. That's all, now it is necessary to carry out voltage stabilization. And this is easy to do if the rectifier unit and the transformer are ready. As you understand, the minus from the rectifier is fed to the first output of the assembly. From the plus of the rectifier, voltage is applied to the second output. The third is a stabilized voltage. Moreover, the input and output must be installed electrolytic capacitors with a capacity of 100 μF and 1000 μF, respectively. That's all, only at the output it is desirable to put a constant resistance (about 2 kOhm), which will allow electrolytes to discharge faster after switching off.

Power supply circuit with adjustable voltage

Make an adjustable power supply on the LM317TIt turns out to be easy, it does not require special knowledge and skills. So, you already have a power unit with a stabilizer. Now you can slightly upgrade it to change the output voltage, depending on what you need. To do this, it is enough to disconnect the first output of the microassembly from the power supply minus. On the output, connect in series two resistances - constant (nominal 240 Ohm) and alternating (5 kΩ). In the place of their connection, the first output of the microassembly is connected. Such simple manipulations allow you to make an adjustable power supply. Moreover, the maximum voltage applied to the input LM317T, may be 25 volts.

Additional Features

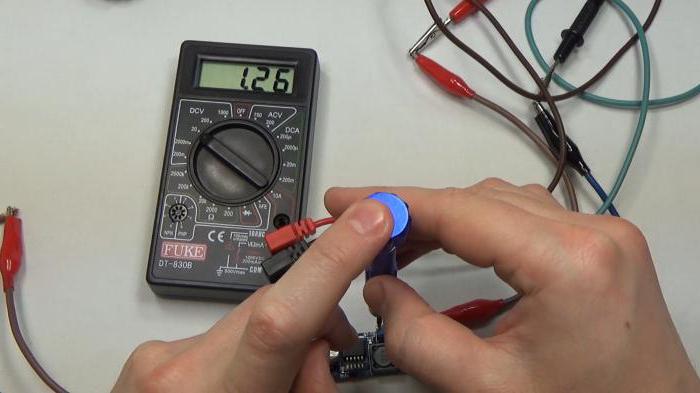

Using microassembly LM317T block diagrampower becomes more functional. Of course, during the operation of the power supply, you will need to monitor the basic parameters. For example, the consumed current or output voltage (this is especially true for a circuit with an adjustment). Therefore, on the front panel you need to mount the indicators. In addition, you need to know if the power supply is plugged in. The duty to notify you about the inclusion in the grid is better placed on the LED. This design is quite reliable, only the power for it must be taken from the output of the rectifier, and not the microassembly.

To control current and voltage you can usedial gauges with graduated scale. But if you want to make a power supply that will not yield to the laboratory one, you can also use LCD displays. However, to measure the current and voltage on the LM317T, the power supply circuit becomes more complicated, since it is necessary to use a microcontroller and a special driver - a buffer element. It allows you to connect an LCD display to the I / O ports of the controller.